Method for preparing hierarchical porous oxygen-rich carbon nanocones from organic metal complexes

A carbon nanocone and hierarchical porous technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, electrochemical generators, etc., to achieve simple equipment and production processes, easy large-scale application, excellent cycle performance and rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

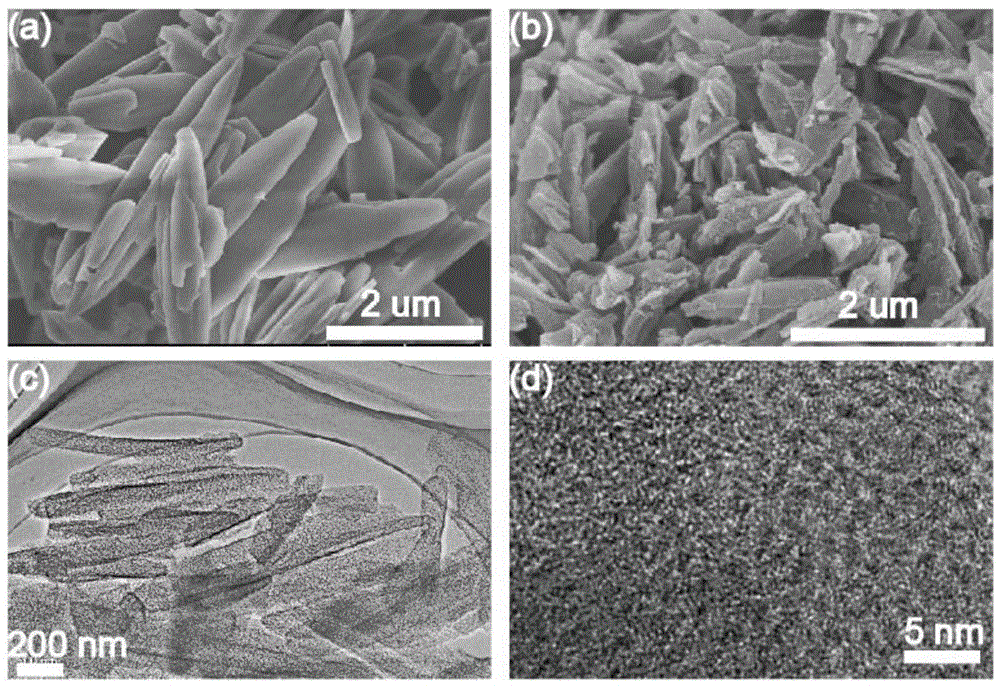

Embodiment 1

[0029] 0.811gFeCl 3 Dissolve in 50mL water, combine magnetic stirring and ultrasonic vibration to make FeCl 3 Fully dissolve. Dissolve 4.803g of o-hydroxybenzoic acid in 50mL of water, combine magnetic stirring and ultrasonic vibration to make FeCl 3 Fully dissolve. Then a homogeneous aqueous solution of o-hydroxybenzoic acid was slowly added to the FeCl 3 In the aqueous solution, stir at room temperature for 2h, once drop into the aqueous solution of o-hydroxybenzoic acid, FeCl 3 The aqueous solution changed from red to deep purple, and the solution began to become cloudy, indicating that the complexation reaction had occurred. After continuous magnetic stirring for 2 h, the obtained precipitate was centrifuged, dried, and then heat-treated in a tube furnace at 600° C. for 2 h under the protection of nitrogen, and finally hierarchical porous heteroatom-rich carbon nanocones were obtained. The prepared hierarchical porous heteroatom-rich carbon nanocone has a length of 2-...

Embodiment 2

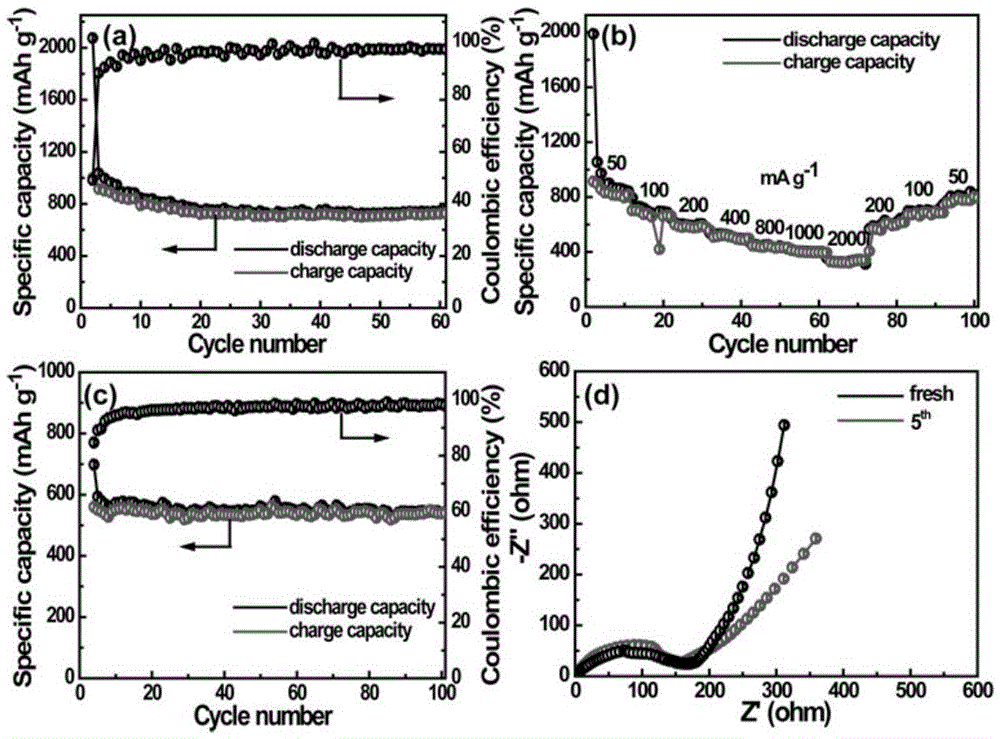

[0031] 0.811gFeCl 3 Dissolve in 50mL water, combine magnetic stirring and ultrasonic vibration to make FeCl 3 Fully dissolve. Dissolve 4.803g of o-hydroxybenzoic acid in 50mL of water, combine magnetic stirring and ultrasonic vibration to make FeCl 3 Fully dissolve. Then the homogeneous o-hydroxybenzoic acid aqueous solution was slowly added dropwise to the FeCl 3 In the aqueous solution, stir at room temperature for 2h, once drop into the aqueous solution of o-hydroxybenzoic acid, FeCl 3 The aqueous solution changed from red to deep purple, and the solution began to become cloudy, indicating that the complexation reaction had occurred. After continuous magnetic stirring for 2 h, the obtained precipitate was centrifuged, dried, and then heat-treated in a tube furnace at 700° C. for 2 h under the protection of nitrogen, and finally hierarchical porous heteroatom-rich carbon nanocones were obtained. When used as a negative electrode material for lithium-ion batteries, at 50...

Embodiment 3

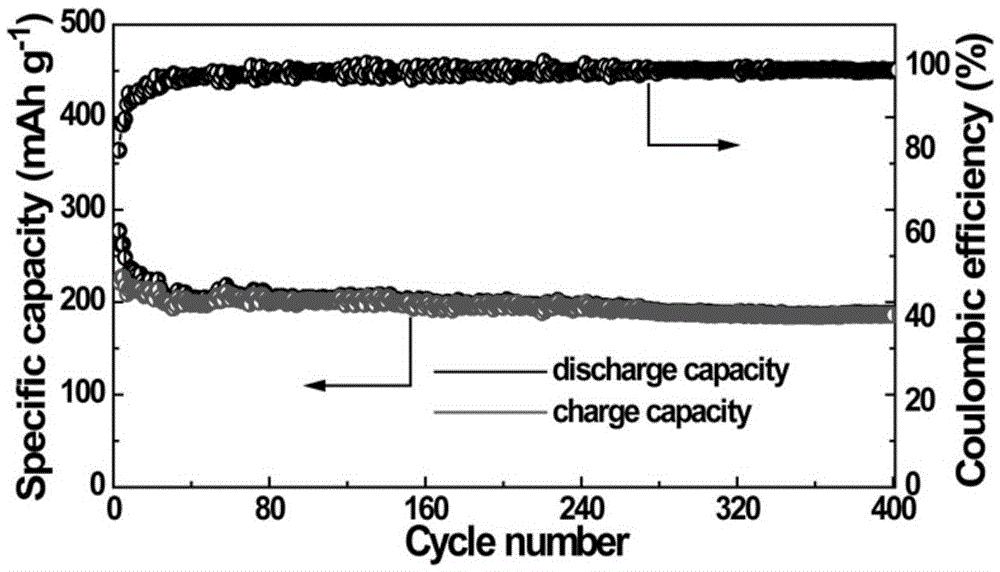

[0033] 2.02Fe(NO 3 ) 3 Dissolve in 50mL water, combine magnetic stirring and ultrasonic vibration to make Fe(NO 3 ) 3 Fully dissolve. Dissolve 4.803g of o-hydroxybenzoic acid in 50mL of water, combine magnetic stirring and ultrasonic vibration to make Fe(NO 3 ) 3 Fully dissolve. Then the homogeneous o-hydroxybenzoic acid aqueous solution was slowly added dropwise to the FeCl 3 In the aqueous solution, stir at room temperature for 2 hours, once the aqueous solution of o-hydroxybenzoic acid is dropped, Fe(NO 3 ) 3 The aqueous solution changed from red to deep purple, and the solution began to become cloudy, indicating that the complexation reaction had occurred. After continuous magnetic stirring for 2 h, the obtained precipitate was centrifuged, dried, and then heat-treated in a tube furnace at 600° C. for 2 h under the protection of nitrogen, and finally hierarchical porous heteroatom-rich carbon nanocones were obtained. The material has multifunctional energy storage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com