Ginger processed pinellia or ginger water processed pinellia processing method

A technology of Pinellia and Ginger, which is applied to medical preparations containing active ingredients, pharmaceutical formulations, medical raw materials derived from ferns/filamentous plants, etc., can solve the problems of low yield, low total organic acid content, The processing time is long and other problems, so as to achieve the effect of simple operation steps, exact curative effect, and anti-reversal and anti-vomiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

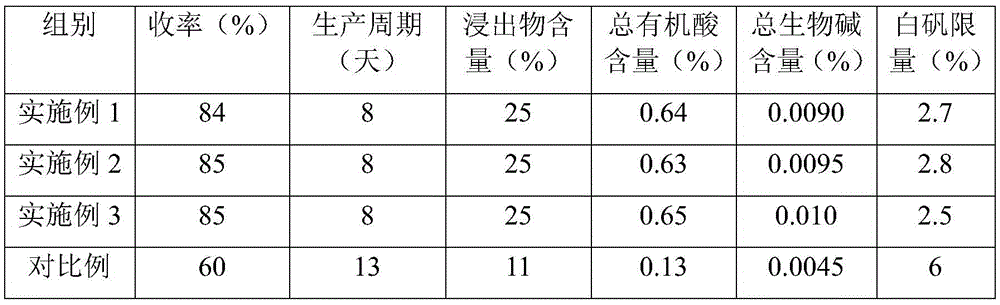

Examples

Embodiment 1

[0030] The concrete steps of the processing method applicable to Pinellia Ginger and Pinellia Jiangshui of the present invention are as follows:

[0031] (1) Purification: remove the impurities in the Pinellia crude drug to obtain a clean Pinellia crude drug;

[0032] (2) Grading: separate pinellia into large, medium and small, and weigh them respectively. The diameter of large pinellia is 1.5cm and above; the diameter of medium pinellia is 1.0-1.5cm; the diameter of small pinellia is less than 1.0cm;

[0033] (3) Soaking: Put the three grades of pinellia into three clean water tanks with constant temperature water bath device in turn, control the temperature at 30°C, soak the big ones for four days, change the water twice a day, until there is no dry core inside; medium Soak the small ones for three days, change the water twice a day until there is no dry core inside; soak the small ones for two days, change the water twice a day until there is no dry core inside;

[0034] (...

Embodiment 2

[0041] The concrete steps of the processing method applicable to Pinellia Ginger and Pinellia Jiangshui of the present invention are as follows:

[0042] (1) Purification: remove the impurities in the Pinellia crude drug to obtain a clean Pinellia crude drug;

[0043] (2) Grading: separate pinellia into large, medium and small, and weigh them respectively. The diameter of large pinellia is 1.5cm and above; the diameter of medium pinellia is 1.0-1.5cm; the diameter of small pinellia is less than 1.0cm;

[0044] (3) Soaking: Put the three grades of pinellia into three clean water tanks with constant temperature water bath device in turn, control the temperature at 35°C, soak the big ones for four days, change the water twice a day, until there is no dry core in the middle; Soak the small ones for three days, change the water twice a day until there is no dry core inside; soak the small ones for two days, change the water twice a day until there is no dry core inside;

[0045] (...

Embodiment 3

[0052] The concrete steps of the processing method applicable to Pinellia Ginger and Pinellia Jiangshui of the present invention are as follows:

[0053] (1) Purification: remove the impurities in the Pinellia crude drug to obtain a clean Pinellia crude drug;

[0054] (2) Grading: separate pinellia into large, medium and small, and weigh them respectively. The diameter of large pinellia is 1.5cm and above; the diameter of medium pinellia is 1.0-1.5cm; the diameter of small pinellia is less than 1.0cm;

[0055] (3) Soaking: Put the three grades of pinellia into three clean water tanks with constant temperature water bath device in turn, control the temperature at 33°C, soak for four days, change the water twice a day, until there is no dry core inside; medium Soak the small ones for three days, change the water twice a day until there is no dry core inside; soak the small ones for two days, change the water twice a day until there is no dry core inside;

[0056] (4) Drying: Dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com