Membrane and method of manufacturing the same

A technology of functional membranes and functional groups, which is applied in the field of functional membranes and their preparation, can solve the problems of increasing flow rate, thickness and preparation costs, needs, etc., and achieve the effect of increasing filtration efficiency and reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, specific contents for implementing the present invention will be described with reference to the drawings.

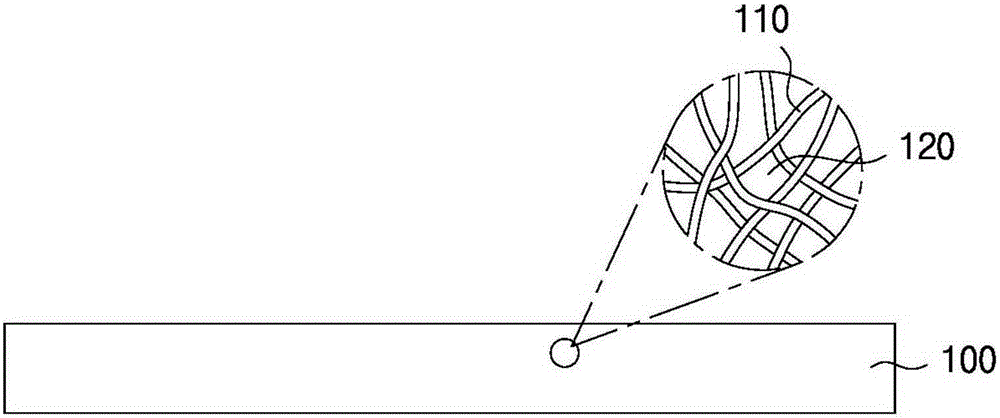

[0036] refer to figure 1 , The functional film 100 of the first embodiment of the present invention is characterized in that the above-mentioned functional film 100 is formed by accumulating nanofibers 110 and forming a nanofiber network with a plurality of pores 120, wherein the above-mentioned nanofibers are made of dopamine It is made by electrospinning the spinning solution mixed with monomer or dopamine polymer, solvent and polymer substance.

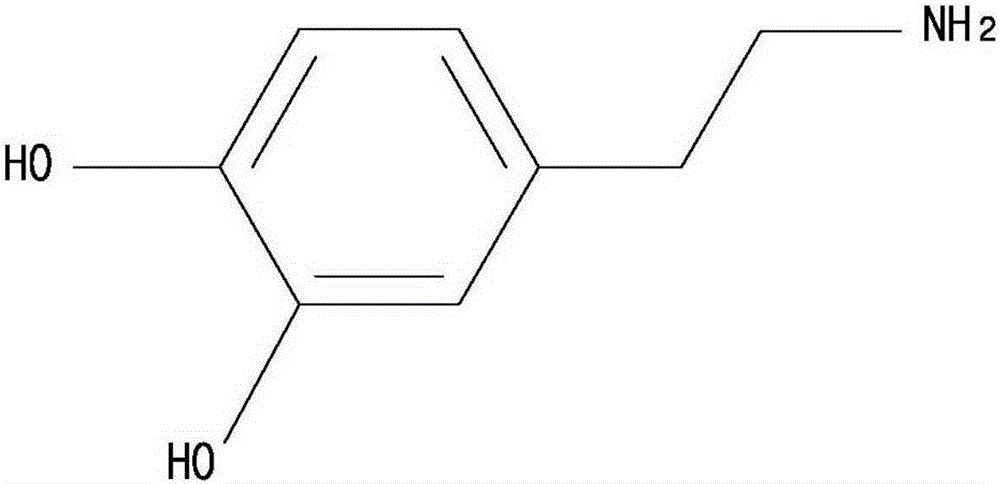

[0037] Among them, such as figure 2 As shown in the chemical formula of , dopamine (DOPAMINE, 3,4-dihydroxyphenylalanine (3,4-dihydroxyphenylalamine)) has a structure in which -NH and -OH are combined in a benzene ring.

[0038] Therefore, the functional membrane 100 according to the first embodiment of the present invention is a nanofibrous network in which nanofibers containing dopamine are accumulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com