Preparation method of titanium fiber

A technology of titanium fiber and titanium wire, which is applied in the field of metal processing, can solve the problems that limit the application of titanium fiber in high-end fields, and achieve the effects of ensuring performance stability, improving product quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

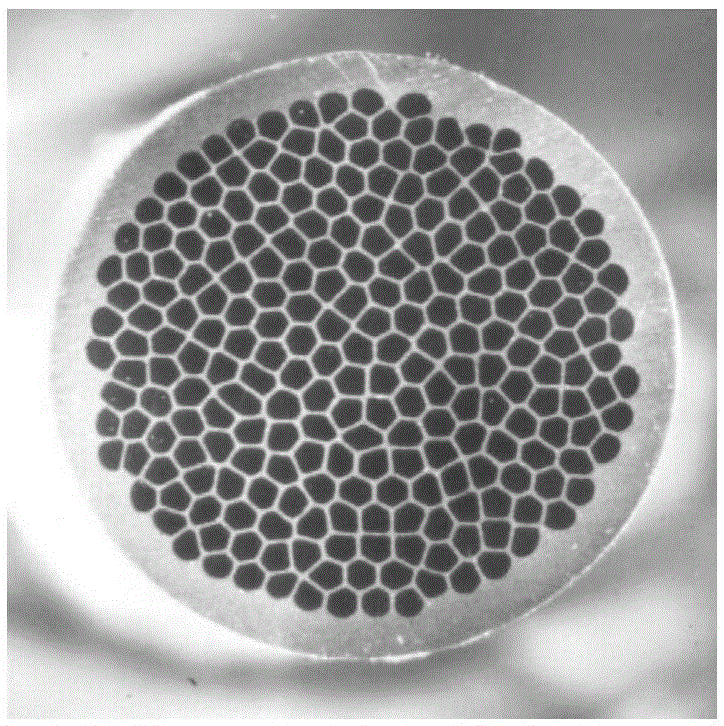

Image

Examples

preparation example Construction

[0021] The preparation method of titanium fiber of the present invention, specifically implement according to the following steps:

[0022] Step 1, using an automatic winding machine with a speed of 60-200r / min to make the titanium wire with a diameter of 0.4-0.6mm go through the pickling tank and the pre-nickel plating tank for activation treatment and nickel plating on the surface, and finally enter the main plating tank to obtain copper plating Titanium wire, in which the grooves are closely connected to prevent the titanium wire from being exposed to air for too long and regenerating an oxide film on the surface;

[0023] The pickling solution in the pickling tank is composed of the following components by mass percentage: nitric acid (mass concentration is 65%) 15% to 25%, hydrofluoric acid (mass concentration is 40%) 3% to 5%, and the balance is water. The sum of the mass percentages of the components is 100%, and the pickling time is 20-30s;

[0024] The composition of...

Embodiment 1

[0033] Step 1, first wipe the pure titanium (TA1) with a wire diameter of 0.4 mm to degrease with alcohol, then clean it with deionized water, and use an automatic winding machine with a speed of 60r / min to make the titanium wire pass through the pickling tank and the pre-coating tank in sequence. The nickel plating tank is activated and the surface is nickel plated, and finally enters the main plating tank to obtain copper-plated titanium wire;

[0034] In the pickling tank, the pickling solution is composed of the following components by mass percentage: nitric acid (mass concentration is 65%) 18%, hydrofluoric acid (mass concentration is 40%) 3%, the balance is water, the above-mentioned components mass percentage The sum is 100%, and the pickling time is 30s;

[0035] The composition of plating solution in the pre-nickel plating bath is: nickel chloride 120g / L, hydrochloric acid (mass concentration is 34%) 160ml / L, wherein the mass concentration of hydrochloric acid is 34%...

Embodiment 2

[0040]Step 1, first wipe the pure titanium (TA1) with a wire diameter of 0.5 mm to degrease with alcohol, then clean it with deionized water, and use an automatic winding machine with a speed of 120r / min to make the titanium wire pass through the pickling tank and the pre-coating tank in sequence. The nickel plating tank is activated and the surface is nickel plated, and finally enters the main plating tank to obtain copper-plated titanium wire;

[0041] Pickling solution in the pickling tank is made up of following components by mass percentage: nitric acid (mass concentration is 65%) 21%, hydrofluoric acid (mass concentration is 40%) 4%, surplus is water, above-mentioned component mass percentage The sum is 100%, and the pickling time is 25s;

[0042] The composition of plating solution in the pre-nickel plating tank is: nickel chloride 130g / L, hydrochloric acid (mass concentration is 34%) 200ml / L, wherein the mass concentration of hydrochloric acid is 34%, and pre-plating c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com