A kind of high-efficiency degradation and denitrification treatment system and treatment method of aquaculture wastewater

A technology for aquaculture wastewater and nitrogen treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Low cost, overcoming slow reproduction and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

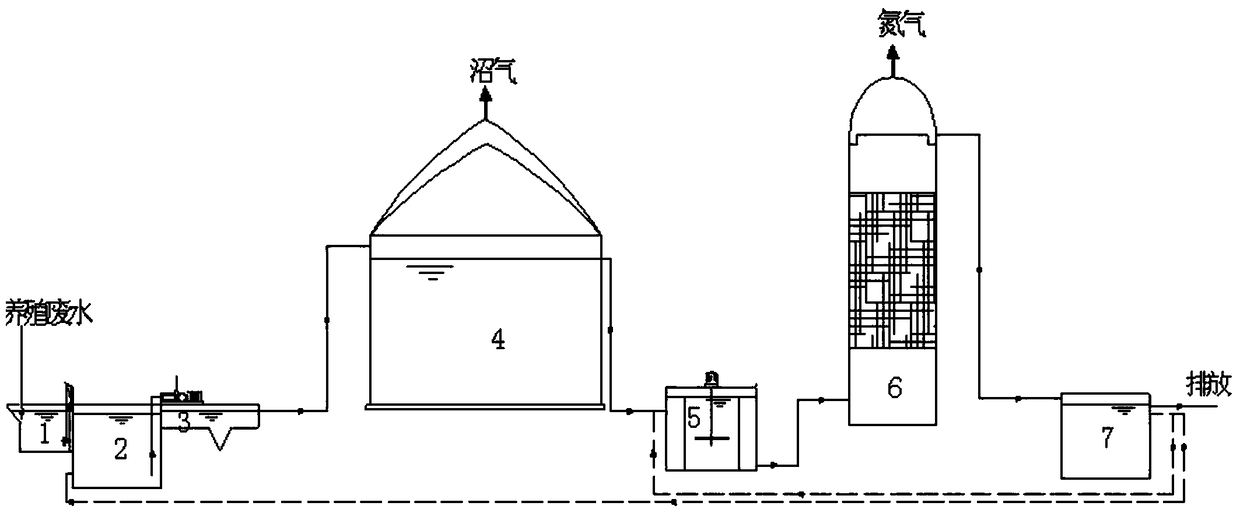

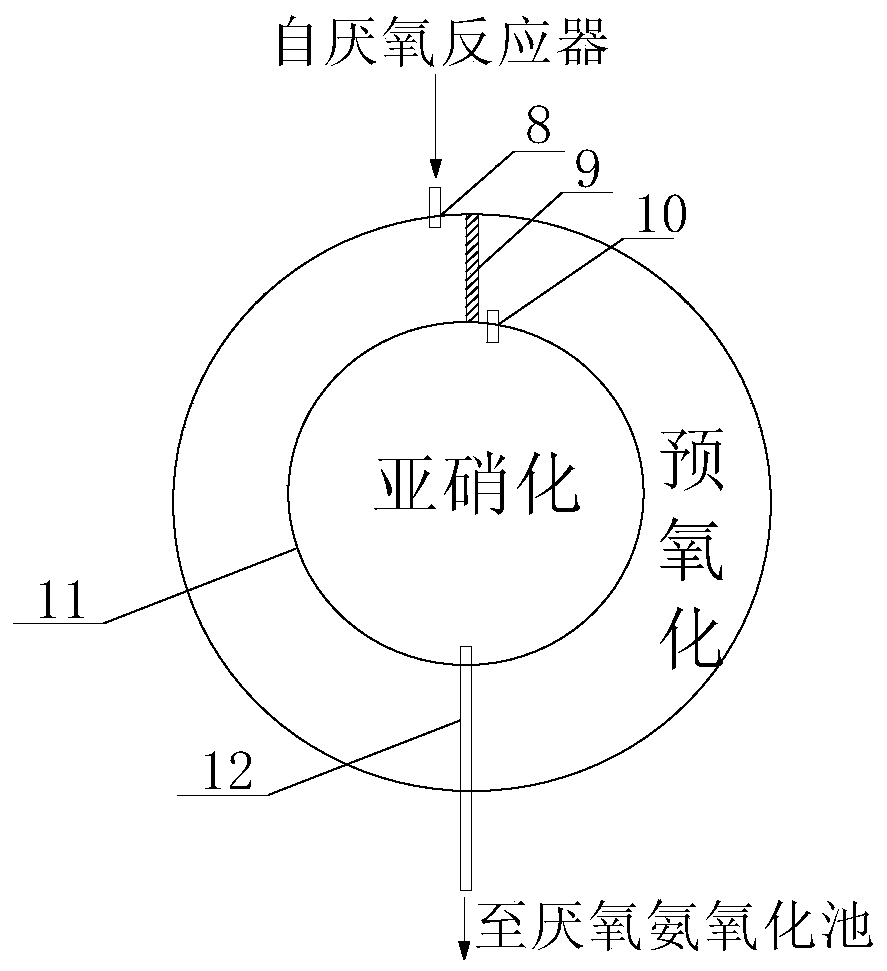

[0048] A high-efficiency degradation and denitrification treatment system for aquaculture wastewater, the structure of which is as follows: figure 1 , figure 2 As shown, it includes a regulating tank 1, a grit chamber 2, a feed tank 3, an anaerobic reactor 4, a pre-oxidation-nitrosation integrated tank 5, anammox reactor 6 and an effluent reflux tank 7 connected in sequence, The anaerobic reactor 4 is an anaerobic internal circulation reactor, and the preoxidation-nitrosation integrated pool 5 includes two cylindrical pool bodies inside and outside, and an annular outer ring pool chamber is formed between the pool body of the outer layer and the pool body of the inner layer , the pool body of the inner layer forms an inner ring pool cavity, and the inner ring pool cavity communicates with the outer ring pool cavity, and a diversion wall 9 is arranged in the outer ring pool cavity of the pre-oxidation-nitrosation integrated pool, and the inner ring pool cavity A paddle mixer ...

Embodiment 2

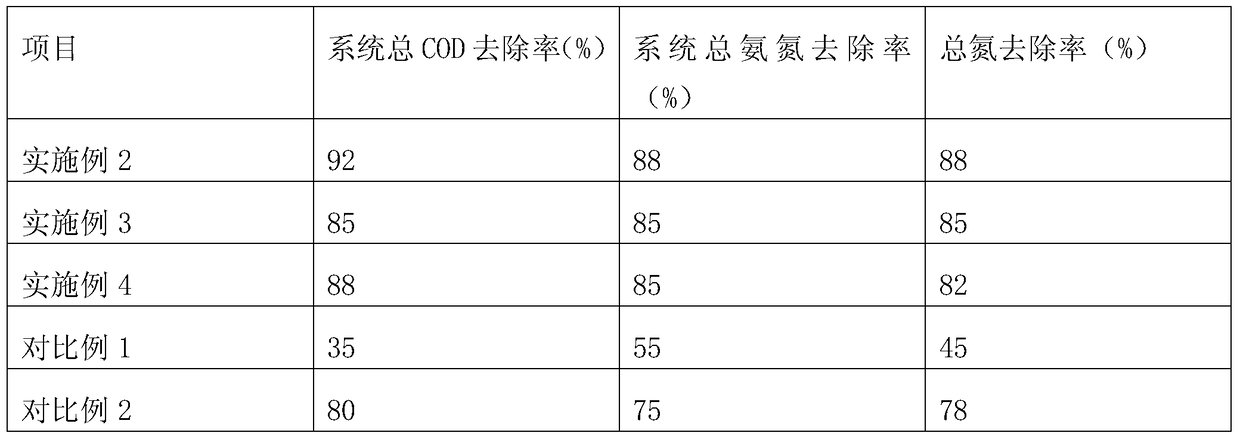

[0052] Treat 30t / d dairy farm wastewater, the wastewater quality is COD 3000~4000mg / L, NH 4 -N 550~650mg / L, pH 7.8~8.0,

[0053] Utilize the treatment method of embodiment 1 treatment system to carry out efficient degradation and denitrification of aquaculture wastewater,

[0054] Regulating pool volume 30m 3 , the size is length × width × height = 5.0 × 3.0 × 2.0m; the volume of the feed tank is 30m 3 , the size is length × width × height = 4.0 × 3.0 × 2.5m; the grit chamber adopts an advection type grit chamber with a volume of 7.2m 3 , the size is length × width × height = 6.0 × 1.0 × 1.2m; the anaerobic reactor adopts IC reactor with a volume of 100m 3 , the size is diameter × height = φ3.6 × 9.8m; the volume of pre-oxidation-denitrification integrated pool is 6m 3 , the size is diameter × height = φ1.5 × 1.0m, the diameter of the inner ring is 1.06m, and a paddle mixer is installed in the chamber of the inner ring pool, and the power of the mixer is 0.75kW; the anammo...

Embodiment 3

[0064] Treat 100t / d of dry pig farm wastewater, the quality of the breeding wastewater is COD2000~3000mg / L, NH 4 -N 600~700mg / L, pH 7.2~7.8

[0065] Utilize the treatment method of embodiment 1 treatment system to carry out efficient degradation and denitrification of aquaculture wastewater,

[0066] Regulating pool volume 100m 3 , the size is length × width × height = 5.0 × 5.0 × 4.0m; the volume of the feed tank is 60m 3 , the size is length × width × height = 5.0 × 4.0 × 3.0m; the grit chamber adopts an advection type grit chamber with a volume of 24m 3 , the size is length × width × height = 10.0 × 2.0 × 1.2m; the anaerobic reactor adopts IC reactor with a volume of 300m 3 , the size is diameter×height=φ5.2×14.0m;

[0067] Pre-oxidation - denitrification integrated pool volume 21m 3 , the size is diameter × height = φ4.2 × 1.5m, the diameter of the inner ring is 3.0m, and a paddle mixer is installed in the chamber of the inner ring pool, and the power of the mixer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com