Dry-mixed mortar for staple shaft masonry and preparation method thereof

A technology of dry-mixed mortar and hidden well, which is applied in the field of construction/road construction, which can solve the problems of affecting vehicle traffic and road landscape, easy seepage manhole cover and road surface, and low strength at the joint, so as to reduce maintenance cost and anti-freezing effect Good, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

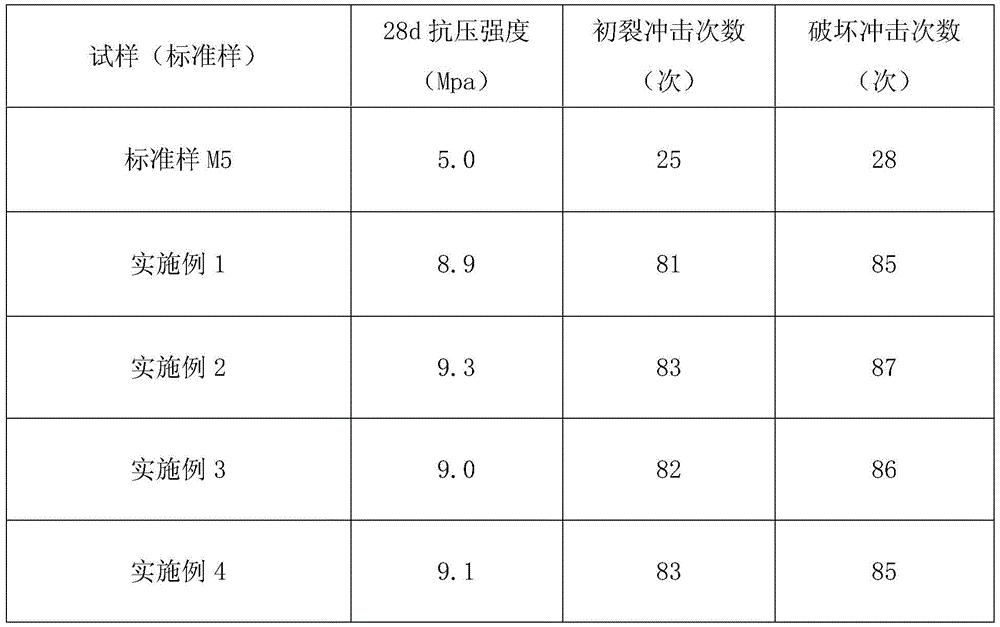

Examples

Embodiment 1

[0026] A dry-mixed mortar for masonry of a hidden well is used for masonry of a vertical shaft, and its component formula is: 12% of cement, 85% of natural sand, and 3% of admixture.

[0027] The preparation method is as follows:

[0028] 1) Dry the natural sand until the moisture content is below 0.5%, sieve, send the particles larger than 4.75mm to the crusher, and send the rest to the mixer by weighing;

[0029] 2) The natural sand larger than 4.75mm is sent into the crusher and is crushed again, repeating step 1);

[0030] 3) Weigh the fly ash Portland cement with strength grade 32.5 into the mixer, and stir and mix for 1 minute;

[0031] 4) Methyl cellulose ether, polyhydroxy acid powder superplasticizer, alkyl silicate silicone waterproofing agent, C 12 h 25 N(EO) 7 (PO) 5 H organosilicon reinforcing agent is premixed according to weight percentage 0.1:0.05:0.05:1 to prepare admixture (total weight percentage is 3%), put into mixer and mix for 1min to obtain dry-mix...

Embodiment 2

[0034] A dry-mixed mortar for masonry of hidden wells is used for masonry and plastering of well covers and road surfaces, and its component formula is: 15% of cement, 80.5% of natural sand, and 4.5% of admixture.

[0035] The preparation method is as follows:

[0036] 1) Dry the natural sand until the moisture content is below 0.5%, sieve, send the particles larger than 4.75mm to the crusher, and send the rest to the mixer by weighing;

[0037] 2) The natural sand larger than 4.75mm is sent into the crusher and is crushed again, repeating step 1);

[0038] 3) Portland cement with a strength grade of 42.5 is weighed and sent to the mixer, and stirred and mixed for 1 minute;

[0039] 4) Mix the mixture of methyl cellulose ether and hydroxypropyl methyl cellulose ether (1:1), polyhydroxy acid powder superplasticizer, naphthalene powder superplasticizer, melamine superplasticizer and sulfamate Mixture of superplasticizer (1:1:1:1), mixture of alkyl silicate and polyalkylhydroxy...

Embodiment 3

[0043] A dry-mixed mortar for masonry of hidden wells is used for masonry of shafts of hidden wells in winter, and its component formula is: 13% of cement, 83% of natural sand, and 4% of admixture.

[0044] The preparation method is as follows:

[0045] 1) Dry the natural sand until the moisture content is below 0.5%, sieve, send the particles larger than 4.75mm to the crusher, and send the rest to the mixer by weighing;

[0046] 2) The natural sand larger than 4.75mm is sent into the crusher and is crushed again, repeating step 1);

[0047] 3) Weigh the ordinary Portland cement with a strength grade of 42.5 and send it into the mixer, and stir and mix for 1 minute;

[0048] 4) A mixture of hydroxypropyl methylcellulose ether, a mixture of melamine superplasticizer and sulfamate superplasticizer (1:1), a mixture of polyalkylhydroxysiloxane, and a silicone reinforcing agent C 12 h 25 N(EO) 7 (PO) 7 H is premixed according to the weight percentage 0.1:0.05:0.05:1 to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com