Low-cost light-weight highly-bulletproof B4C/SiC composite ceramic bulletproof plate and preparation method thereof

A composite ceramic and low-cost technology, which is applied in the field of low-cost, lightweight, high-ballistic-resistant B4C/SiC composite ceramic ballistic plates and their preparation, can solve the problems of poor wearing comfort, difficult processing and molding, and low production efficiency, and achieve uniform ballistic resistance. The effect of unification, improving service reliability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

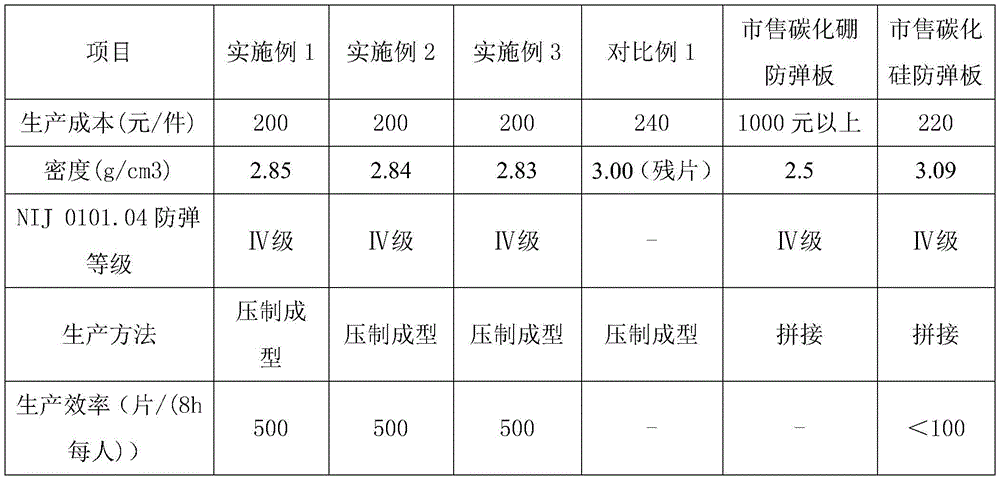

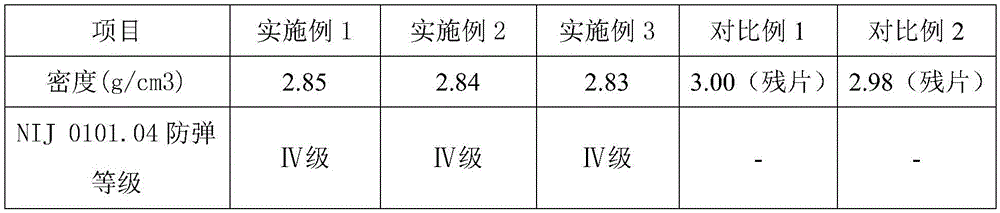

Embodiment 1

[0042] A low-cost light weight high ballistic performance B 4 The preparation method of C / SiC composite ceramic bullet-proof board adopts silicon carbide granulated powder as raw material, and described silicon carbide granulated powder comprises the following components by mass percentage: silicon carbide micropowder 70%, phenolic resin 6%, carbon black 2 %, graphite 2%, boron carbide 10%, polyvinyl alcohol 10%;

[0043] The preparation steps of silicon carbide granulated powder raw material are as follows:

[0044] Get silicon carbide micropowder, phenolic resin, carbon black, graphite, boron carbide and mix evenly, then add polyvinyl alcohol with a mass concentration of 12%, ammonia water and deionized water with a mass concentration of 25%, mix evenly, and the addition amount of ammonia water is silicon carbide micropowder , phenolic resin, carbon black, graphite, 0.1% of the quality of the mixed material of boron carbide, the addition of deionized water is 45% of the qua...

Embodiment 2

[0052] A low-cost light weight high ballistic performance B 4 The preparation method of C / SiC composite ceramic bulletproof plate adopts silicon carbide granulated powder as raw material, and the described silicon carbide granulated powder includes the following components in mass percentage: 60% of silicon carbide micropowder, 8% of phenolic resin, 3% of carbon black %, graphite 1%, boron carbide 16%, polyvinyl alcohol 12%;

[0053] The preparation steps of silicon carbide granulated powder raw material are as follows:

[0054] Get silicon carbide micropowder, phenolic resin, carbon black, graphite, boron carbide and mix homogeneously, add the polyvinyl alcohol of mass concentration 14%, the ammoniacal liquor and the deionized water that mass concentration is 27% mix homogeneously, the addition amount of ammoniacal liquor is silicon carbide micropowder , phenolic resin, carbon black, graphite, 0.2% of the quality of the mixed material of boron carbide, the addition of deioni...

Embodiment 3

[0062] Low cost, light weight and high bulletproof performance B 4 The preparation method of C / SiC composite ceramic bullet-proof board adopts silicon carbide granulated powder as raw material, and described silicon carbide granulated powder comprises the following components in mass percentage: silicon carbide micropowder 68%, phenolic resin 7%, carbon black 3.5% %, graphite 1.5%, boron carbide 9%, polyvinyl alcohol 11%;

[0063] The preparation steps of silicon carbide granulated powder raw material are as follows:

[0064] Get silicon carbide micropowder, phenolic resin, carbon black, graphite, boron carbide and mix homogeneously after adding the polyvinyl alcohol of mass concentration 16%, the ammoniacal liquor and the deionized water that mass concentration is 28% mix homogeneously, the addition amount of ammoniacal liquor is silicon carbide micropowder , phenolic resin, carbon black, graphite, 0.4% of the quality of the mixed material of boron carbide, the addition of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com