Early-strength ethers polycarboxylic acid water reducing agent and preparation method thereof

An early-strength, polycarboxylic acid technology, applied in the field of ether early-strength polycarboxylate water reducer and its preparation, can solve the problems of small synergy space, short setting time, high early strength, and achieve safe operation. Good properties, low reaction temperature and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

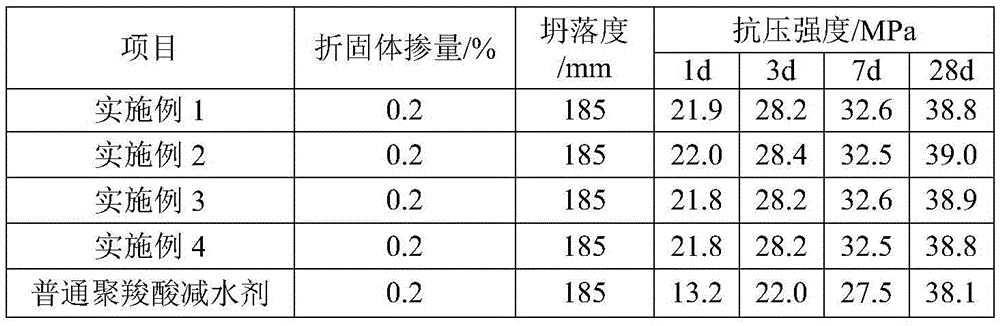

Examples

Embodiment 1

[0024] The preparation method of ether early-strength polycarboxylate water reducer is as follows:

[0025] Under normal temperature conditions, add 440g of deionized water into a 1L glass flask, start stirring, add 360g of methallyl polyoxyethylene ether with a molecular weight of 6000, and after fully dissolving, add 1.8g of hydrogen peroxide with a concentration of 27.5wt%. Then add successively a solution A mixed with 14.4g acrylic acid, 19.8g sodium p-styrene sulfonate, and 40g deionized water and a solution B mixed with 0.72g vitamin C, 1.08g mercaptoacetic acid, and 80g deionized water, dropwise Adding time is 1.5h, after stirring for 1h, add NaOH solution with a concentration of 30wt% to neutralize to a pH value of 5-7, and then add water to a solid content of 40wt%, to obtain an ether-based early-strength polycarboxylate superplasticizer.

Embodiment 2

[0027] The preparation method of ether early-strength polycarboxylate water reducer is as follows:

[0028] At room temperature, add 193.8g of deionized water to a 1L glass flask, start stirring, add 360g of methallyl polyoxyethylene ether with a molecular weight of 7000, and after it is fully dissolved, add 3.6g of ammonium persulfate, and then drop Add solution A mixed with 25.2g of acrylic acid, 10.8g of sodium methacrylate, and 40g of deionized water and solution B of 1.44g of sodium bisulfite, 2.16g of mercaptopropionic acid, and 80g of deionized water, drop Adding time is 2 hours, after stirring for 1 hour, add NaOH solution with a concentration of 30wt% to neutralize to a pH value of 5-7, and then add water to a solid content of 40wt% to obtain an ether-based early-strength polycarboxylate superplasticizer.

Embodiment 3

[0030] The preparation method of ether early-strength polycarboxylate water reducer is as follows:

[0031] At room temperature, add 300g of deionized water to a 1L glass flask, start stirring, add 360g of methallyl polyoxyethylene ether with a molecular weight of 8000, and after fully dissolving, add 1g of 27.5wt% hydrogen peroxide and 1.5 g ammonium persulfate, then dropwise added solution A mixed with 21.6g acrylic acid, 9g sodium p-styrene sulfonate, 40g deionized water and 1.08g vitamin C, 0.8g mercaptoacetic acid, 1g mercaptopropionic acid, 80g deionized water The solution B mixed with ionic water, the dropping time is 2.5h, after stirring for 0.5h, add a NaOH solution with a concentration of 30wt% to neutralize to a pH value of 5-7, and then add water to a solid content of 40wt%, to obtain ethers Strong polycarboxylate superplasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com