Method for processing Fischer-Tropsch wax and lubricating oil base oil and its preparation method

A technology for Fischer-Tropsch wax and hydrogen oil, applied in the field of preparing lubricating base oil and lubricating base oil, can solve the problems of environmental pollution of waste solvent, loss of heavy base oil, reduction of yield of base oil, etc. Its properties are improved, the degree of isomerization is increased, and the effect of avoiding excessive lightweighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

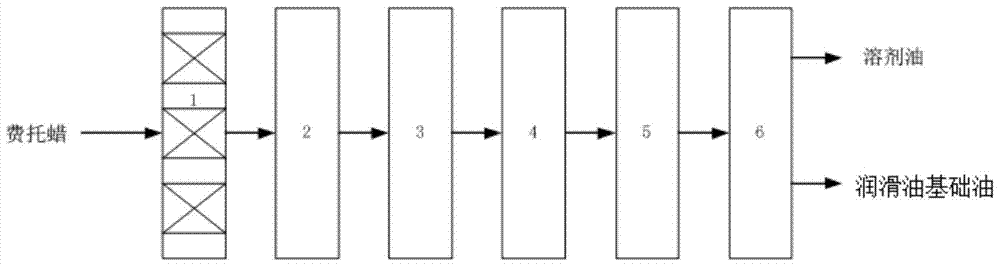

[0065] According to a preferred embodiment of the present invention, the method of the present invention comprises:

[0066] (1) In the first hydrofinishing reaction zone, Fischer-Tropsch wax is contacted with successively loaded hydrofinishing catalyst A1, hydrofinishing catalyst A2 and hydrofinishing catalyst A3, wherein the hydrofinishing catalyst A1 includes fluorine-containing , a hydrogenation catalyst of at least one additive component in boron and phosphorus, the hydrofinishing catalyst A2 includes a hydrogenation catalyst containing fluorine and / or molecular sieves, and the hydrofinishing catalyst A3 includes a hydrogenation catalyst that does not contain fluorine and does not contain Hydrogenation catalysts containing molecular sieves;

[0067] (2) contacting the product obtained in step (1) with the hydroisomerization catalyst a1 in the first wax hydroconversion reaction zone;

[0068] (3) contacting the product obtained in step (2) with the hydroisomerization cata...

Embodiment 1

[0083] In this example, a Fischer-Tropsch synthetic wax is used as a raw material, and its properties are shown in Table 1.

[0084] The catalyst of the present embodiment is prepared by the following method:

[0085] Catalyst a1 adopts the catalyst prepared by the embodiment 1 in CN101942320A with platinum as an active component loaded on the ZSM-22 molecular sieve (molecular sieve aperture is 0.55nm), wherein based on the catalyst total amount, the mass fraction of platinum metal is 0.35% .

[0086] Catalyst a2 is prepared according to the embodiment 6 in CN1382526A with platinum as the catalyst that the active component is loaded on the SAPO-11 (molecular sieve aperture is 0.60nm) molecular sieve / alumina carrier, wherein with catalyst total amount as benchmark, platinum metal The mass fraction is 0.3%, and the rest is carrier. Based on the carrier, the mass fraction of SAPO-11 molecular sieve in the carrier is 75%, and the rest is alumina.

[0087] Catalyst b is the Pt / be...

Embodiment 2

[0131] The raw material Fischer-Tropsch synthetic wax used in this example is the same as that in Example 1.

[0132] The preparation method of the catalyst used in this example is similar to that in Example 1, except that the molecular sieve in the hydroisomerization catalyst a1 of this example is MCM-22 molecular sieve (the pore size of the molecular sieve is 0.55nm).

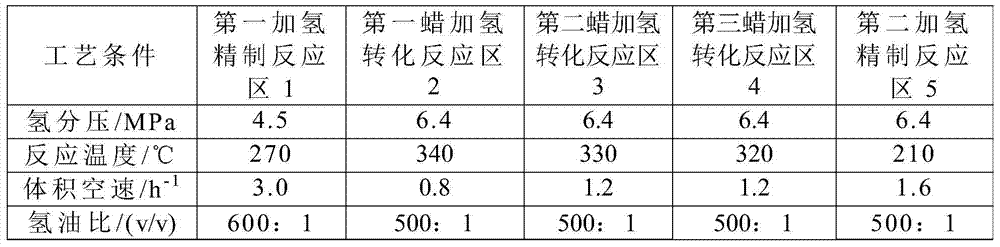

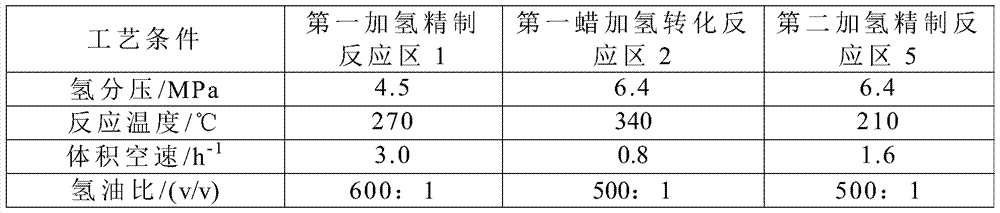

[0133] Adopt the technical process identical with embodiment 1 to process this raw material, wherein, difference is:

[0134] The catalyst loading volume ratio of the first wax hydroconversion reaction zone 2, the second wax hydroconversion reaction zone 3 and the third wax hydroconversion reaction zone 4 is 5:3:2, and the operating conditions are shown in Table 14. See Table 15 for the material balance after separation in distillation zone 6. The properties of the lubricating base oil obtained are shown in Table 16. Moreover, it can be seen with the naked eye that the lubricating base oil obtained by the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com