Method for extracting lysozyme from egg white or whole egg juice

A technology of egg liquid and egg white, applied in the biological field, can solve the problems that are not conducive to co-separation and preparation of egg white, and achieve high purity and biological activity, cost reduction, and high biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

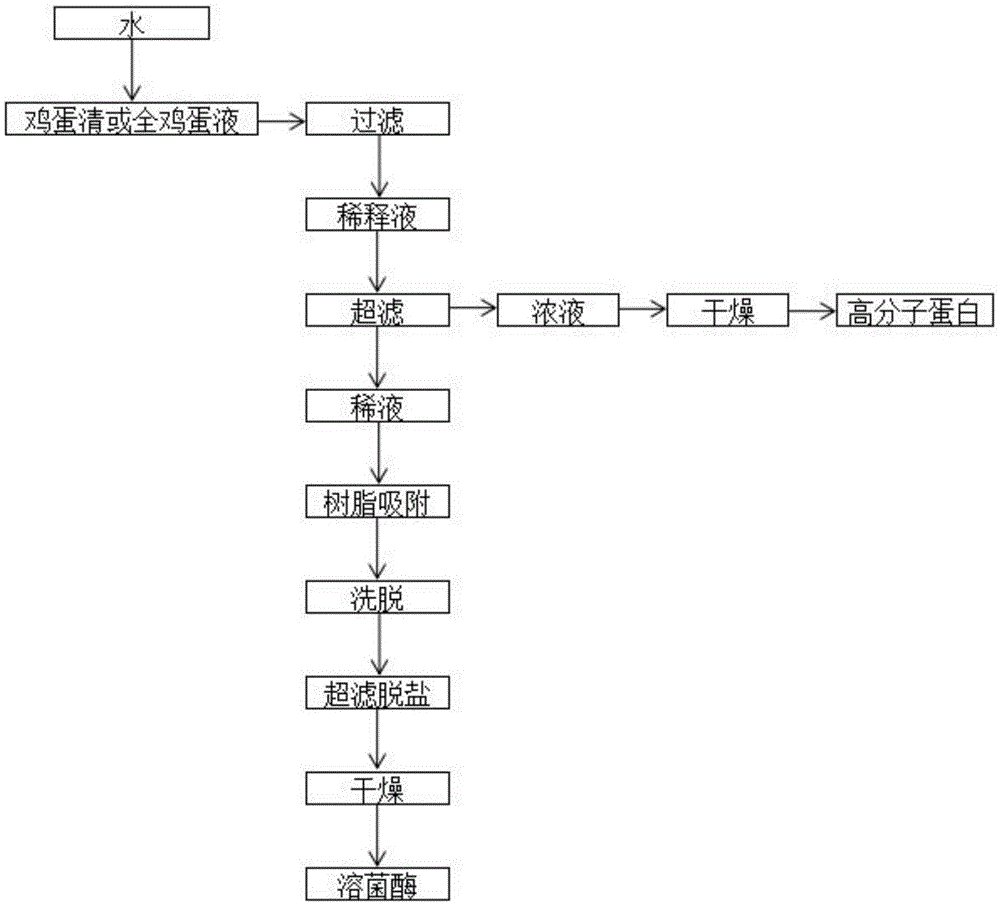

[0034] Such as figure 1 As shown, the method for extracting lysozyme from egg white or whole egg liquid of the present embodiment comprises the following steps:

[0035] (1) Add 1 times the weight of water to egg white or whole egg liquid, mix evenly, filter with a filter cloth, remove the lipid components in the egg yolk, and obtain a dilution;

[0036] (2) The diluted solution obtained in step (1) is ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 20000Da to obtain a thin solution and a concentrated solution, and the concentrated solution is dried to obtain a high-molecular protein, and the high-molecular protein is used for Preparation of ovalbumin and ovotransferrin;

[0037] (3) Adding the cation exchange resin that model is 001*7 to the weak liquid that step (2) obtains is adsorbed, and the weight ratio of described weak liquid and resin is 1:3, obtains the resin after adsorption;

[0038] (4) eluting the adsorbed resin obtained in ste...

Embodiment 2

[0042] Such as figure 1 As shown, the method for extracting lysozyme from egg white or whole egg liquid of the present embodiment comprises the following steps:

[0043] (1) Add 5 times the weight of water to egg white or whole egg liquid, mix evenly, filter with a filter cloth, remove the lipid components in the egg yolk, and obtain a dilution;

[0044] (2) The diluted solution obtained in step (1) is ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 30000Da to obtain a thin solution and a concentrated solution, and the concentrated solution is dried to obtain a high-molecular protein, and the high-molecular protein is used for Preparation of ovalbumin, ovotransferrin, ovomucin and vitellin;

[0045] (3) in the weak liquid that step (2) obtains, add the cationic exchange resin that model is AmberliteIR-120 to adsorb, and the weight ratio of described weak liquid and resin is 1:5, obtains the resin after adsorption;

[0046] (4) eluting the ad...

Embodiment 3

[0050] Such as figure 1 As shown, the method for extracting lysozyme from egg white or whole egg liquid of the present embodiment comprises the following steps:

[0051] (1) Add 10 times the weight of water to egg white or whole egg liquid, mix evenly, filter with a filter cloth, remove the lipid components in the egg yolk, and obtain a dilution;

[0052](2) The diluted solution obtained in step (1) is ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 15000Da to obtain a thin solution and a concentrated solution, and the concentrated solution is dried to obtain a high-molecular protein, and the high-molecular protein is used for Preparation of ovalbumin, ovotransferrin, ovomucin and vitellin;

[0053] (3) add the macroporous adsorption resin that model is D101 in the dilute liquid that step (2) obtains and adsorb, and the weight ratio of described dilute liquid and resin is 1:8, obtains the resin after adsorption;

[0054] (4) eluting the adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com