Method for preparing biological butyl alcohol with marine algae as raw materials

A technology of biological butanol and a production method, applied in the field of bioengineering, can solve problems such as affecting the decomposition and utilization of polysaccharides, and achieve the effects of improving high-efficiency output and promoting industrialization development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

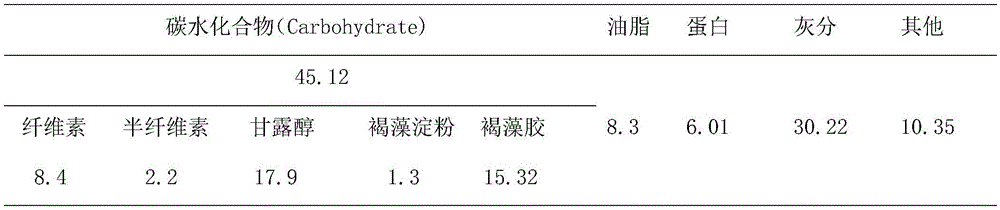

Method used

Image

Examples

Embodiment 1

[0042] Seaweed pretreatment and saccharification: After pretreatment of seaweed homogenate with a concentration of 180g / L, suction filtration, centrifugation and solid-liquid separation, the solid part was taken for saccharification, the amount of cellulase added was 15FPU / g substrate, and the enzymatic hydrolysis treatment was carried out for 3 days. The enzymatic hydrolysis solution is vacuum-distilled to half of the original volume after suction filtration and centrifugation for solid-liquid separation;

[0043] Fermentation medium preparation: After the seaweed hydrolyzate is cooled to room temperature, add this as the main raw material, add ammonium sulfate until the ammonium sulfate in the hydrolyzate is 10.8g / L, add potassium dihydrogen phosphate until the content of potassium dihydrogen phosphate in the hydrolyzate is 5.0g / L, and 1.1g / L, add sodium acetate until the sodium acetate content in the hydrolyzate is 3.0g / L, add potassium dihydrogen phosphate until the conten...

Embodiment 2

[0052] Seaweed pretreatment and saccharification: After pretreatment, the laver homogenate with a concentration of 90g / L was pretreated, suction filtered, centrifuged to separate the solid from the liquid, and the solid part was taken for saccharification. The amount of cellulase added was 15FPU / g substrate, and the enzymatic hydrolysis treatment was carried out for 3 days. The enzymatic hydrolysis solution is vacuum-distilled to half of the original volume after suction filtration and centrifugation for solid-liquid separation;

[0053] Preparation of fermentation medium: After the seaweed hydrolyzate is cooled to room temperature, add this as the main raw material, add ammonium sulfate until the ammonium sulfate in the hydrolyzate is 5.4g / L, add potassium dihydrogen phosphate until the content of potassium dihydrogen phosphate in the hydrolyzate is 5.0g / L, 1.1g / L Add sodium acetate until the sodium acetate content in the hydrolyzate is 3.0g / L, add potassium dihydrogen phosph...

Embodiment 3

[0057] Seaweed pretreatment and saccharification: pretreat the undaria pinnata homogenate with a concentration of 120g / L, suction filter, centrifuge to separate the solid from the liquid, take the solid part for saccharification, add 15 FPU / g substrate of cellulase, and enzymatically hydrolyze for 3 days , the enzymolyzed solution was filtered and centrifuged for solid-liquid separation, and the liquid part was distilled under reduced pressure to half of the original volume;

[0058] Fermentation medium preparation: After the seaweed hydrolyzate is cooled to room temperature, add this as the main raw material, add ammonium sulfate until the ammonium sulfate in the hydrolyzate is 5.4g / L, add potassium dihydrogen phosphate until the content of potassium dihydrogen phosphate in the hydrolyzate is 5.0g / L, 1.1g / L Add sodium acetate until the sodium acetate content in the hydrolyzate is 3.0g / L, add potassium dihydrogen phosphate until the content of potassium dihydrogen phosphate in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com