Honey extractor and honey concentration method

A honey shaker and honey technology, applied in the fields of honey harvesting, beekeeping, food science, etc., can solve the problems of inferior honey and other problems, achieve the effect of increasing yield, high activity, and ensuring the activity of honey

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

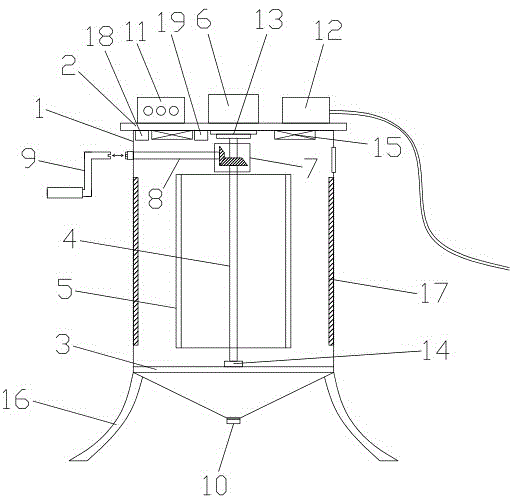

[0034] A honey shaker, comprising a barrel body 1, an upper support rail 2, a lower support rail 3, a main shaft 4, and a centrifugal frame 5, the upper support rail 2 is arranged on the upper part of the barrel body 1, and the lower support rail is arranged on the lower part The gear 3 is provided with a main shaft 4 between the upper supporting crosspiece 2 and the lower supporting crosspiece 3, and the main shaft 4 is fixedly provided with a centrifugal frame 5. It is characterized in that: the upper supporting crosspiece 2 is provided with a motor 6, and the motor 6 Drive main shaft 4 to rotate; Also comprise manual rotating device, described manual rotating device comprises gear transmission mechanism 7, transmission rod 8, rocking handle 9, and gear transmission mechanism 7 is located at the top of main shaft 4, and one end of transmission rod 8 and gear transmission mechanism The other end passes through the bucket body 1 and is connected to the rocking handle 9, and the...

Embodiment 2

[0041] A method for concentrating honey, characterized in that said method comprises the following steps:

[0042] 1) Take out the honeycomb to be shaken from the beehive;

[0043] 2) Clean up the bees on the honeycomb;

[0044] 3) Put the cleaned honeycomb in step 2) into the honey shaker, shake the honey, separate the thin honey from the uncapped honeycomb, and obtain the thin honey and the honeycomb with the cap;

[0045] 4) Use a honey cutting knife to cut off the cover of the honeycomb containing the cover in step 3);

[0046] 5) Put the honey spleen after step 4) into the honey shaker, and shake the honey to get concentrated honey.

[0047] The dilute honey obtained in the step 3) is used for bee feed.

[0048] The concentrated honey obtained by the method contains 30% royal jelly, and the sugar content is more than or equal to 40 degrees Baume.

[0049] During the steps 3) and 5) of the honey shaker, the temperature inside the honey shaker is controlled to be 15°C. ...

Embodiment 3

[0051] A method for concentrating honey, characterized in that said method comprises the following steps:

[0052] 1) Take out the honeycomb to be shaken from the beehive;

[0053] 2) Clean up the bees on the honeycomb;

[0054] 3) Put the cleaned honeycomb in step 2) into the honey shaker, shake the honey, separate the thin honey from the uncapped honeycomb, and obtain the thin honey and the honeycomb with the cap;

[0055] 4) Use a honey cutting knife to cut off the cover of the honeycomb containing the cover in step 3);

[0056] 5) Put the honey spleen after step 4) into the honey shaker, and shake the honey to get concentrated honey.

[0057] The dilute honey obtained in the step 3) is used for bee feed.

[0058] The concentrated honey obtained by the method contains 40% royal jelly, and the sugar content is more than or equal to 40 degrees Baume.

[0059] During the steps 3) and 5), the temperature inside the honey shaker is controlled to be 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com