Method for modifying magnetic bentonite by biosurfactant and application of modified magnetic bentonite

A biological surface, active agent technology, applied in the methods of using microorganisms, chemical instruments and methods, radioactive purification, etc., can solve the problems of difficult and rapid separation and recovery, affecting recycling, etc., to achieve strong chemical stability, ensure contact, and reaction. mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

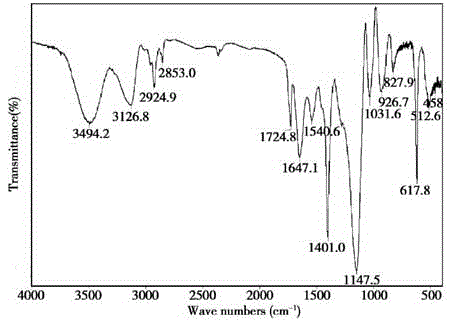

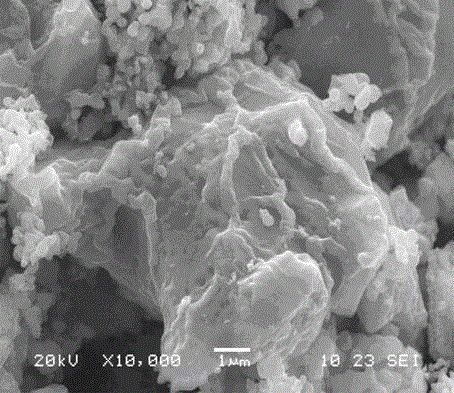

Image

Examples

Embodiment 1

[0035] The first step, the enrichment culture and domestication of strains

[0036] Air-dried 100g of rice straw and 100g of chaff were crushed and sieved to obtain powdery biomass, and 500g of farmland soil samples were collected from field farmland. Use powdered biomass as the initial compost material, bury it in the farmland soil, and add 10g of air-dried and crushed bark as a filler to improve the porosity of the compost. After culturing at 4-5°C for 7 days, store them until use.

[0037] Take 10g of compost samples and place them in a 250mL Erlenmeyer flask filled with 90mL of sterile water, vibrate for 25min, then stand still for 30min to obtain a soil suspension. Take 2mL of soil suspension and inoculate it into the enrichment medium, put it into a constant temperature incubator with a temperature of 25°C and a rotation speed of 220r / min for shaking culture for 3-5 days.

[0038] Draw 1mL of the above-mentioned enriched culture solution and inoculate it into the ferme...

Embodiment 2

[0047] The first step, the enrichment culture and domestication of strains

[0048] Specifically with embodiment 1.

[0049] The second step, the preparation of biosurfactant

[0050] After the acclimatized strains were continuously cultured in the enriched culture medium for 1 day, 1 mL of the bacterial liquid was inoculated into the fermentation medium at 4.5%, adjusted to a pH of 6, and cultured at a constant temperature at a temperature of 25°C and a rotation speed of 200r / min. In the tank, continue to shake and cultivate for 2.5 days, take out the fermentation broth, centrifuge, collect flocculent precipitates, and then use dichloromethane to resuspend, filter, extract, centrifuge, collect precipitates, and dry naturally at room temperature to obtain the purified biological surface active agent.

[0051] The third step, biosurfactant magnetically modified bentonite

[0052] Weigh 4g of bentonite into a 500mL three-neck flask, add 100mL of deionized water, 120mL of ethy...

Embodiment 3

[0057] The first step, the enrichment culture and domestication of strains

[0058] Specifically with embodiment 1.

[0059] The second step, the preparation of biosurfactant

[0060] After the acclimatized strains were continuously cultured in the enriched culture medium for 1 day, 1 mL of the bacterial liquid was inoculated into the fermentation medium at a rate of 4.5%, adjusted to a pH value of 7, and cultured at a constant temperature of 25°C and 200r / min. In the tank, continue to shake and cultivate for 2.5 days, take out the fermentation broth, centrifuge, collect flocculent precipitates, and then use dichloromethane to resuspend, filter, extract, centrifuge, collect precipitates, and dry naturally at room temperature to obtain the purified biological surface active agent.

[0061] The third step, biosurfactant modified magnetic bentonite

[0062]Weigh 5g of bentonite into a 500mL three-neck flask, add 100mL of deionized water, 120mL of ethylene glycol, and 60mL of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com