Special geonet material prepared by modifying polyester and polyethylene mixed wastes and preparation method for special material

A technology of polyethylene and geonet, which is applied in the field of waste plastic treatment and resource utilization, can solve the problems of poor quality and low utilization value, and achieve the effect of high value, low production cost and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

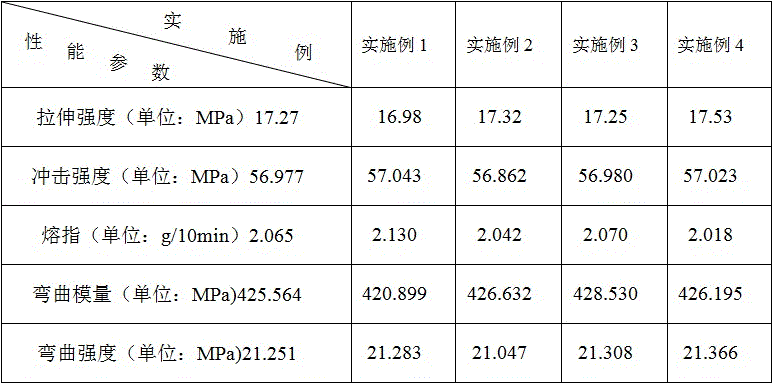

Examples

Embodiment 1

[0025] In this embodiment, a special material for geonet is modified by using waste polyester bottle flakes (PET) and mixed polyethylene waste (PE). The special material for geonet is prepared from the following raw materials in parts by weight Made: 100 parts of PET / PE mixed waste, 6 parts of chlorinated polyethylene, 1.5 parts of maleic anhydride, 2 parts of silane coupling agent, 2 parts of paraffin oil, 0.5 part of ferrous sulfate, wherein the PET / PE mixed The waste consisted of 10wt% polyester bottle flakes (PET) and 90wt% polyethylene mixed waste (PE).

[0026] The above-mentioned geonet special material prepared from polyester waste bottle flakes (PET) and polyethylene mixed waste (PE) is prepared by the following method, including the following steps:

[0027] (1) Separately crush polyester waste bottle flakes (PET) and polyethylene mixed waste (PE) into materials of similar size, clean them, dehydrate and dry them, and then mix them evenly in proportion to obtain PET / ...

Embodiment 2

[0031] In this embodiment, a special material for geonet is modified by using waste polyester bottle flakes (PET) and mixed polyethylene waste (PE). The special material for geonet is prepared from the following raw materials in parts by weight Made: 100 parts of PET / PE mixed waste, 8 parts of chlorinated polyethylene, 1 part of maleic anhydride, 2 parts of silane coupling agent, 1 part of paraffin oil, 0.5 part of ferrous sulfate, wherein the PET / PE mixed The waste consisted of 20 wt% polyester bottle flakes (PET) and 80 wt% polyethylene mixed waste (PE).

[0032] The method adopted in this embodiment to prepare the above-mentioned geonet special material is the same as that in Embodiment 1.

Embodiment 3

[0034] In this embodiment, a special material for geonet is modified by using waste polyester bottle flakes (PET) and mixed polyethylene waste (PE). The special material for geonet is prepared from the following raw materials in parts by weight Made: 100 parts of PET / PE mixed waste, 8 parts of chlorinated polyethylene, 2 parts of maleic anhydride, 3 parts of silane coupling agent, 2 parts of paraffin oil, 0.5 part of ferrous sulfate, wherein the PET / PE mixed The waste consisted of 30wt% polyester bottle flakes (PET) and 70wt% polyethylene mixed waste (PE).

[0035] The method adopted in this embodiment to prepare the above-mentioned geonet special material is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com