A kind of preparation method of imidization SMA modified cationic styrene-acrylic sealing primer

A technology of imidization and sealing primer, applied in the direction of coating, etc., can solve the problems of accelerated aging process of coating film, high surface tension, insufficient smooth surface of decorative coating, etc., to achieve excellent substrate permeability and salt resistance. Good analytical performance, excellent anti-pan-alkali effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

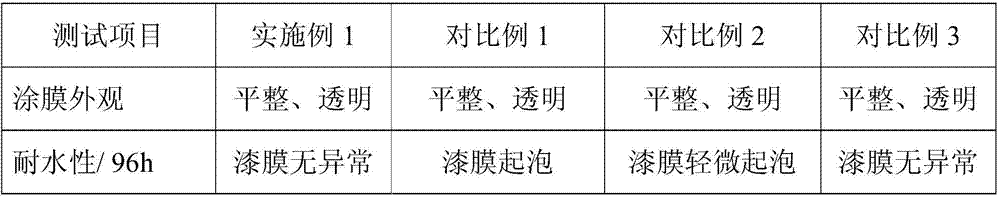

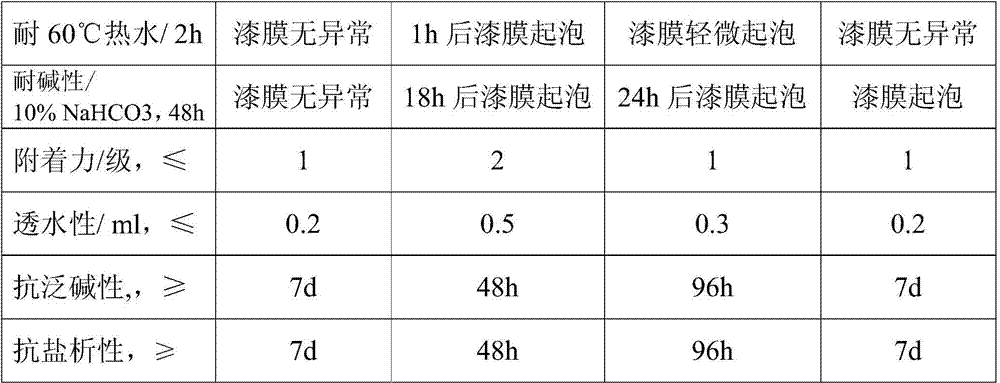

Examples

Embodiment 1

[0012] An imidized SMA modified cationic styrene-acrylic sealing primer is prepared by high-speed dispersion with a mixer according to the weight ratio of the following raw material formula: the formula consists of: 20%-35% deionized water, 1%-5% propylene glycol , 0.1%~0.5% defoamer, 0.5%~2% dispersant, 0.05%~0.3% wetting agent, 0.1%~0.4% fungicide, 4%~8% titanium dioxide, 5%~12% heavy Calcium carbonate, 5% to 10% kaolin, 1% to 3% talc, 30% to 50% imidized SMA modified cationic styrene-acrylic emulsion, 2% to 6% coalescent, 0.5% to 3% Thickening rheological agent, 0.2% ~ 1% pH regulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com