Latex for water-based interior wall priming paint as well as preparation method and application of latex

An interior wall primer, water-based technology, applied in the field of coatings, can solve the problems that the emulsion is not competent for the performance of the interior wall primer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

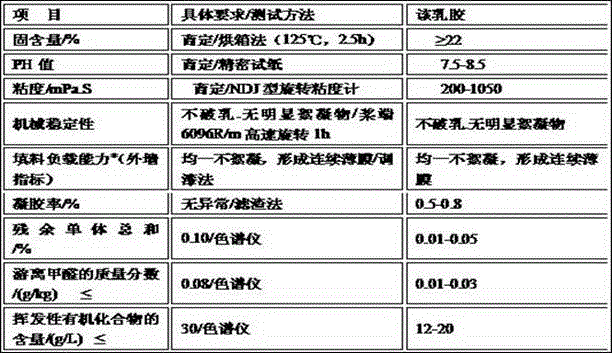

Image

Examples

Embodiment 1

[0042] A kind of latex for water-based interior wall primer, wherein, by weight percentage, comprising:

[0043] Vinyl acetate 10.1%

[0044] Styrene 9.0%

[0045] Butyl Acrylate 7.4%

[0046] Pyrrole 1.1%

[0047] Fatty acid polyoxyethylene ester 0.8%

[0048] Sodium bicarbonate 1.05%

[0049] Fatty acid esters 0.3%

[0050] Persulfate 0.25%

[0051] Deionized water 70.0%

[0052]According to the above formula, add deionized water, pyrrole and fatty acid polyoxyethylene ester into the reactor, heat and stir, and control the temperature at 60°C. After the pyrrole and fatty acid polyoxyethylene ester are completely dissolved, add one-fifth of the monomer (acetic acid Vinyl ester, styrene and butyl acrylate) were pre-dispersed for 0.5h, the temperature was controlled at about 50°C, and a uniform emulsion was obtained in the reactor;

[0053] Then the temperature of the emulsion in the reactor was raised to 65°C, and a quarter of the pre-prepared 5% persulfate aqueous sol...

Embodiment 2

[0059] A kind of latex for water-based interior wall primer, wherein, by weight percentage, comprising:

[0060] Styrene 10.6%

[0061] Isooctyl Acrylate 10.0%

[0062] Methacrylate 9.3%

[0063] Morpholine 1.1%

[0064] Hydroxypropyl Methyl Cellulose 1.2%

[0065] Ammonia 1.05%

[0066] Phosphates 0.5%

[0067] Peroxide 0.15%

[0068] Deionized water 66.1%

[0069] According to the above formula, add deionized water, morpholine, and hydroxypropyl methylcellulose into the reactor, heat and stir, and control the temperature at 65°C. After the morpholine and hydroxypropylmethylcellulose are completely dissolved, add five minutes One of the monomers (styrene, isooctyl acrylate and methacrylic acid) was pre-dispersed for 0.3h, the temperature was controlled at about 55°C, and a uniform emulsion was obtained in the reactor;

[0070] Then the temperature of the emulsion in the reactor was raised to 60°C, and a quarter of the pre-prepared 5% peroxide aqueous solution was adde...

Embodiment 3

[0076] A kind of latex for water-based interior wall primer, wherein, by weight percentage, comprising:

[0077] Methyl methacrylate 12.1%

[0078] Triethylene glycol dimethacrylate 10%

[0079] Pyrrole 0.9%

[0080] Hydroxypropyl Methyl Cellulose 0.5%

[0081] Fatty acid polyoxyethylene ester 0.5%

[0082] Sodium bicarbonate 0.06%

[0083] Ammonia 0.09%

[0084] Citrates 0.5%

[0085] Redox initiator 0.25%

[0086] Deionized water 75.0%

[0087] According to the above formula, add deionized water, pyrrole, and hydroxypropyl methylcellulose into the reactor, heat and stir, and control the temperature at 55°C. After the pyrrole and hydroxypropylmethylcellulose are completely dissolved, add one-fifth The monomers (butyl acrylate and triethylene glycol dimethacrylate) were pre-dispersed for 0.6h, the temperature was controlled at about 45°C, and a uniform emulsion was obtained in the reactor;

[0088] Then the temperature of the emulsion in the reactor was raised to 65°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com