Modified potassium silicate styrene-acrylic emulsion and preparation method thereof as well as preservative-free and solvent-free water-based polymer material and preparation method thereof

A water-based polymer, styrene-acrylic emulsion technology, applied in coatings and other directions, can solve the problems of high efflorescence risk, human and environmental hazards, large organic solvents, etc., and achieve excellent anti efflorescence and low VOC effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment provides a modified potassium silicate styrene-acrylic emulsion and a preparation method thereof, the preparation method of which is:

[0068] (1) Mixing and reacting the first part of the quaternary ammonium salt containing unsaturated double bonds, organosilicon-modified potassium silicate, and the first part of water at 35° C. to obtain the first mixed solution;

[0069] (2) Mix the first part of emulsifier, sodium bicarbonate, methyl methacrylate, butyl acrylate, the second part of quaternary ammonium salt containing unsaturated double bonds and styrene with the second part of water to obtain the second mixed solution ;

[0070] (3) Mix the second part of emulsifier with the third part of water, control the system temperature to 75°C, then mix with the first part of potassium persulfate, the first part of the second mixed solution, and the first part of the silane coupling agent to obtain the third mixed solution;

[0071] (4) Add dropwise the seco...

Embodiment 2、 comparative example 1~5

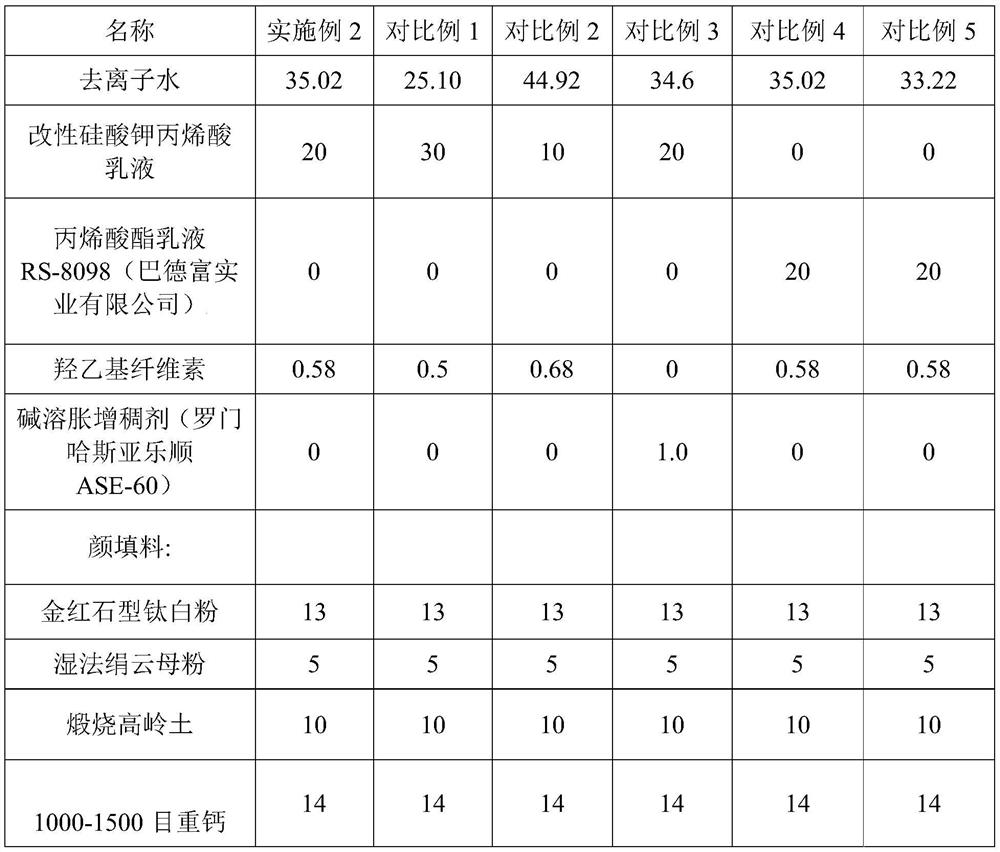

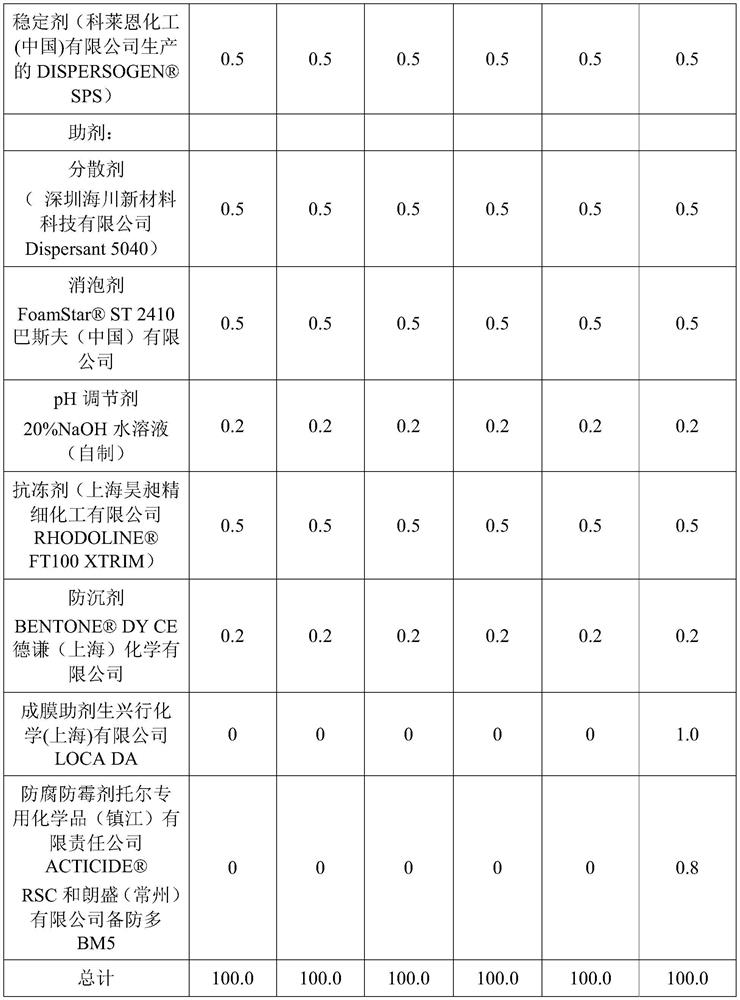

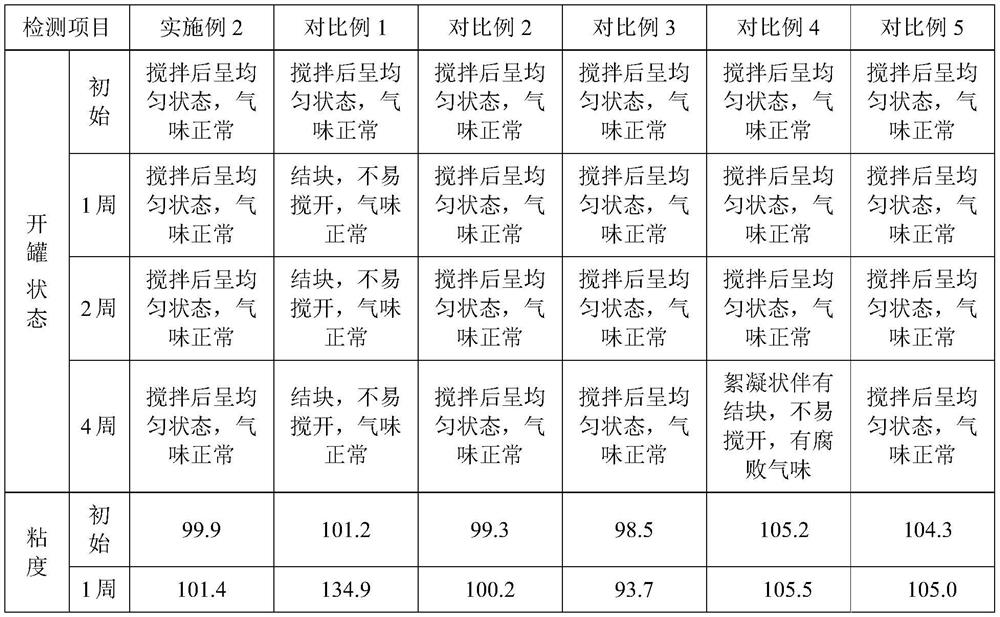

[0084] Example 2 provides a preservative-free and solvent-free water-based polymer material and a preparation method thereof, and Comparative Examples 1-5 provide a water-based polymer material. The dosage of each component is shown in Table 1 (parts by weight).

[0085] Table 1

[0086]

[0087]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com