Bacillus licheniformis gene engineering bacterium capable of producing polysaccharide flocculant at high yield and establishment method thereof

A technology of Bacillus licheniformis and genetically engineered bacteria, which is applied in the field of genetic engineering and microbial fermentation, can solve the problems of unclear regulation mechanism and low flocculation activity of polysaccharide flocculants, and achieve the effect of improving flocculation activity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

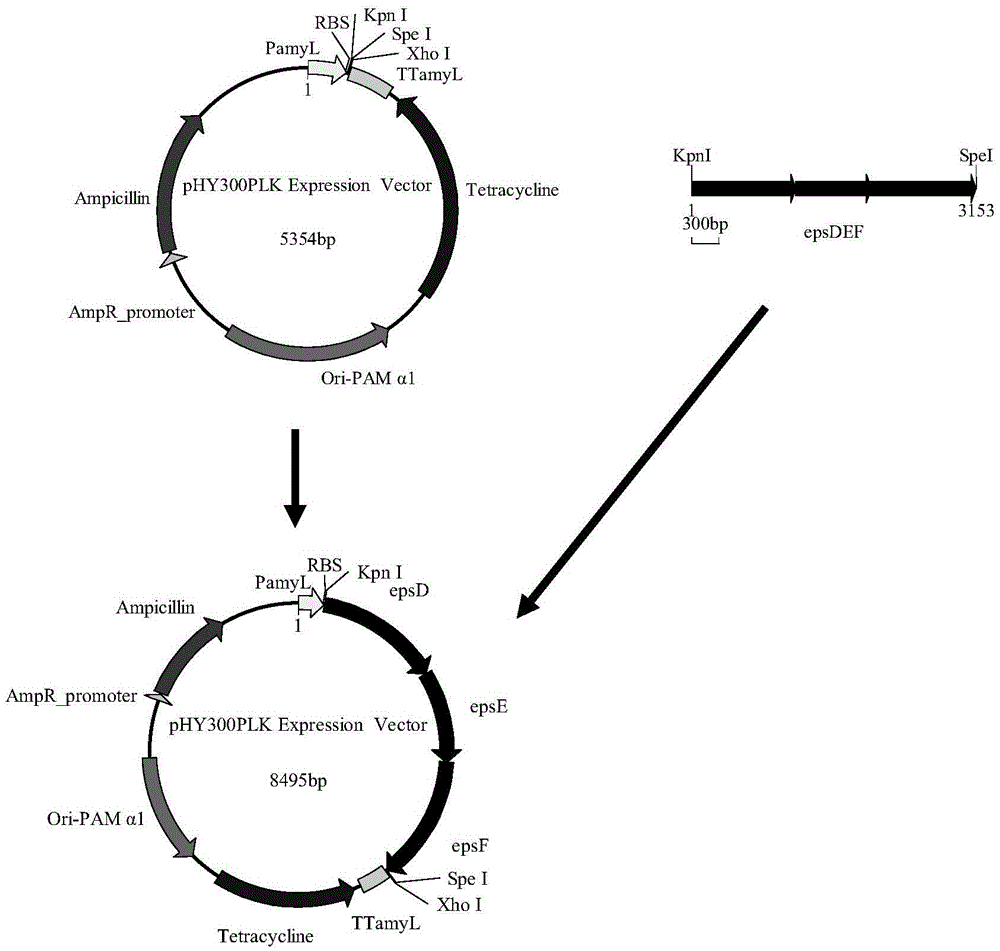

[0030] Embodiment 1: the construction of recombinant expression vector PHY300-epsDEF

[0031] Design PCR primers for amplifying the espDEF gene fragment.

[0032] The upstream and downstream primers are:

[0033] Upstream primer: GGGGTACCATGACAAGAACGGTTTTGT (the underline is the KpnI restriction site)

[0034] Downstream primer: GGACTAGTTCACTGTCCTTCTGCCGC (the underline is the SpeI restriction site)

[0035] Using BacilluslicheniformisCGMCC2876 genomic DNA as a template, perform the following PCR procedures: (1) 94°C, 5min; (2) 94°C, 30s; (3) 55°C, 30s (4) 72°C, 1min, (2)~(4) Repeat step by step for 35 cycles; (5) 72°C, 10min, and store at 4°C.

[0036] The PCR reaction system is shown in Table 1.

[0037] Table 1

[0038]

[0039] The PCR product and the expression vector PHY300PLK-PamyL-TTamyL were double-digested with restriction endonucleases KpnI and SpeI respectively, and after recovery, the PCR product and the expression vector were treated with T4 DNA ligase at...

Embodiment 2

[0040] Embodiment 2: the construction of bacillus licheniformis genetically engineered bacteria HN301-1

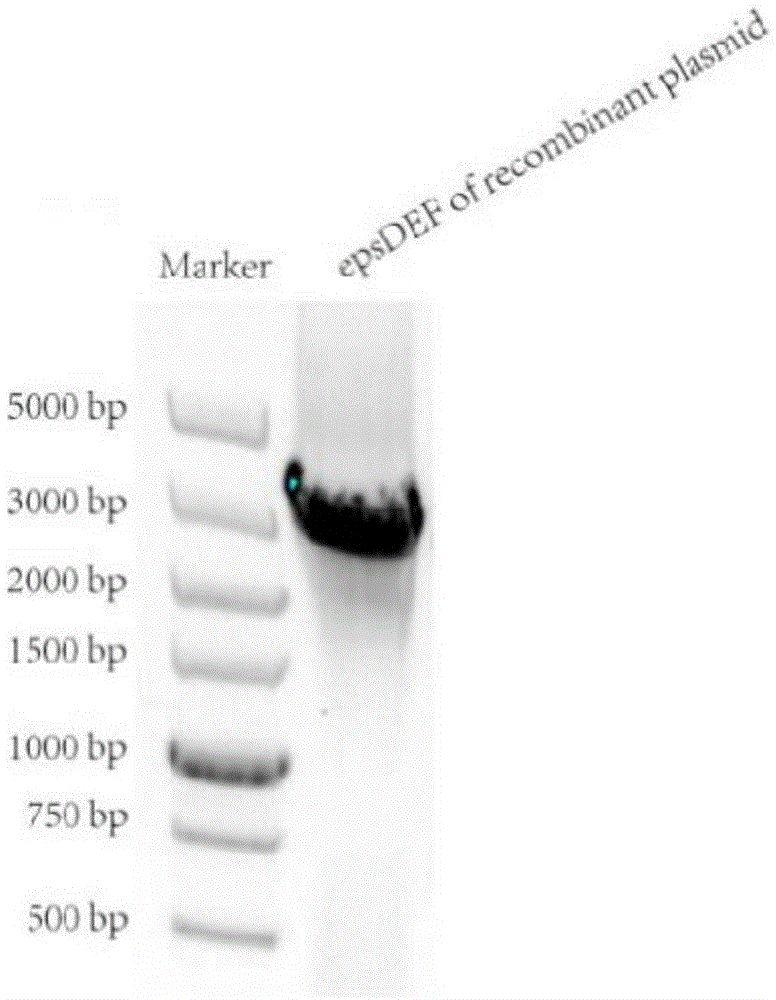

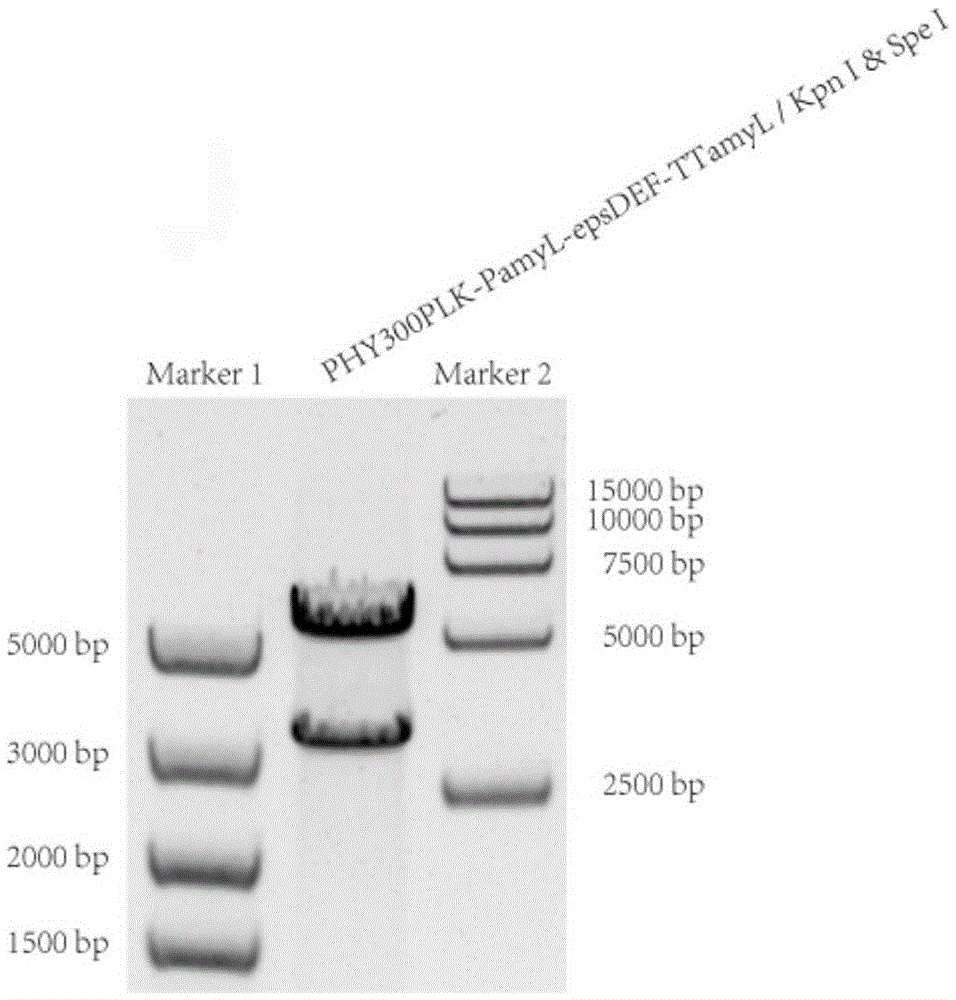

[0041] After the PHY300-epsDEF overexpression plasmid was extracted and concentrated, it was transformed into Bacillus licheniformis by electric shock, recovered at 37°C for 5 hours, coated with a tetracycline-resistant plate, and cultured at 37°C for 12 hours to screen transformants. After the transformant was extracted from the plasmid, it was verified by PCR and double enzyme digestion (such as figure 2 and 3 ). Thus, the Bacillus licheniformis engineering strain HN301-1 overexpressing the glycosyltransferase gene epsDEF was obtained.

[0042] The specific steps of electroconversion are as follows:

[0043] Preparation of Bacillus licheniformis competent:

[0044] (1) Inoculate a ring of B. licheniformis in 50mL LB medium, 37°C, 200rmin -1 Cultivate overnight for 12 hours;

[0045] (2) Take 1 mL of the overnight culture solution and put it into 50 mL of the growth ...

Embodiment 3

[0054] Embodiment 3: Utilize Bacillus licheniformis and its genetically engineered bacteria fermentation to prepare polysaccharide flocculant

[0055] Inoculate the Bacillus licheniformis CGMCC2876 starting strain and the genetically engineered bacteria described in Example 2 in the liquid seed medium, 37°C, 200rmin -1 Cultivate for 16 hours, prepare seed culture solution, inoculate in polysaccharide flocculant fermentation medium with an inoculum size of 4% (V / V), 37°C, 200rmin -1 Cultivate and carry out the experiment of producing polysaccharide flocculant by fermentation. After 56 hours, respectively measure the flocculation activity of the fermentation broth and the output of the polysaccharide flocculant, and draw a growth curve (such as Figure 4 and 5 ). The final flocculation activity of the epsDEF gene overexpressed recombinant genetically engineered bacteria fermentation broth was 5332U / mL, which was 90% higher than the final flocculation activity of the original ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com