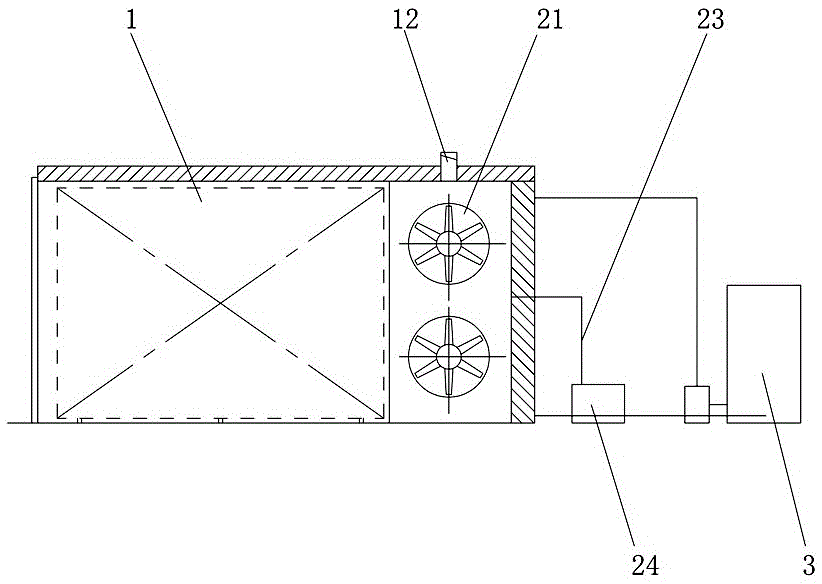

Method and device for drying easily-dried wood

A technology of drying device and drying method, which is applied in the field of wood processing, can solve the problems of low energy utilization rate, long drying time, and slow drying speed, and achieve the effects of reducing drying energy consumption, improving drying efficiency, and increasing drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

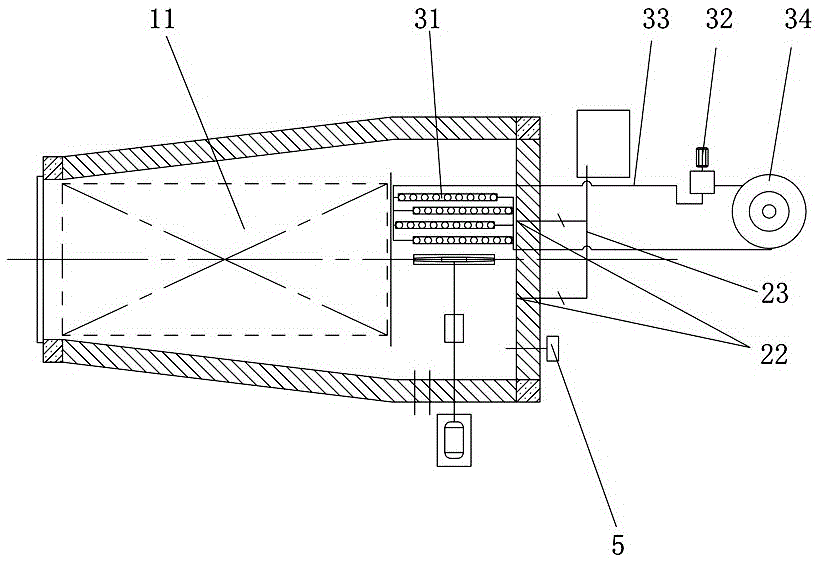

[0031] A drying method for easy-drying wood, specifically comprising the following steps:

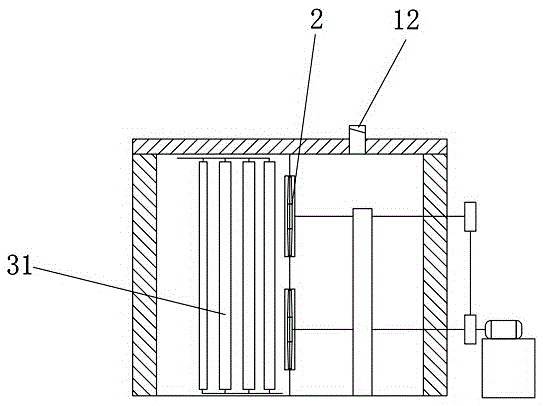

[0032] (1) Wood accumulation: stack the wet masson pine sawn timber into the wood accumulation area in the drying kiln;

[0033] In this embodiment, according to the LY / T1068-2012 standard, the sawn timber of wet masson pine is piled up, the thickness of the sawn timber is 25mm, the length is 2.0m, and the initial moisture content is about 75%; the height of the pile is 1.5m, and the pile The width is 1.5m; the thickness and width of the spacer are 25mm and 35mm respectively, and the length of the spacer is 1.6m; and the temperature and moisture content sensors are placed in the pile according to the standard requirements;

[0034] (2) Heating and preheating: close the door and air inlet of the drying kiln body, and quickly raise the kiln temperature to 42°C under the condition of ventilation and dehumidification, and keep it warm for 1.0 hours, so that the wet masson pine saw is fully ...

Embodiment 2

[0041] A drying method for easy-drying wood, specifically comprising the following steps:

[0042] (1) Wood accumulation: Wet poplar veneers are piled into the wood accumulation area of the drying kiln body;

[0043] In this example, the wet poplar veneer is stacked according to the LY / T1068-2012 standard. The thickness of the poplar veneer is 1.2mm, the width is 1.22m, the length is 2.44m, and the average moisture content is 92%. During the process, first stack 15 layers of veneers in the thickness direction to form a veneer layer with a thickness of 18mm, and then place a layer of spacers, alternately, the height of the stack is 1.2m, and the width of the stack is 1.22m; The thickness and width are 20mm and 30mm respectively, and the length of the spacer is 1.4m. And install the temperature and moisture content sensors in the single plate stack according to the standard requirements.

[0044] (2) Preheating: Close the door and air inlet of the drying kiln body, and quick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com