Method for preparing GaN/conductive substrate composite material by magnetron sputtering method and application of GaN/conductive substrate composite material on lithium ion battery

A composite material and magnetron sputtering technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

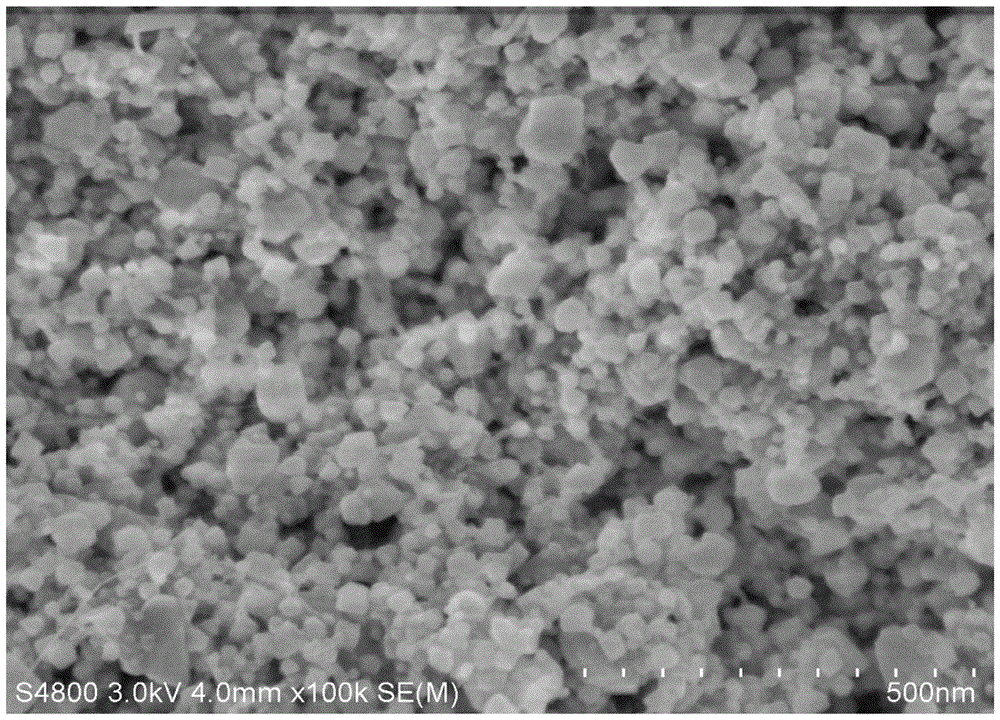

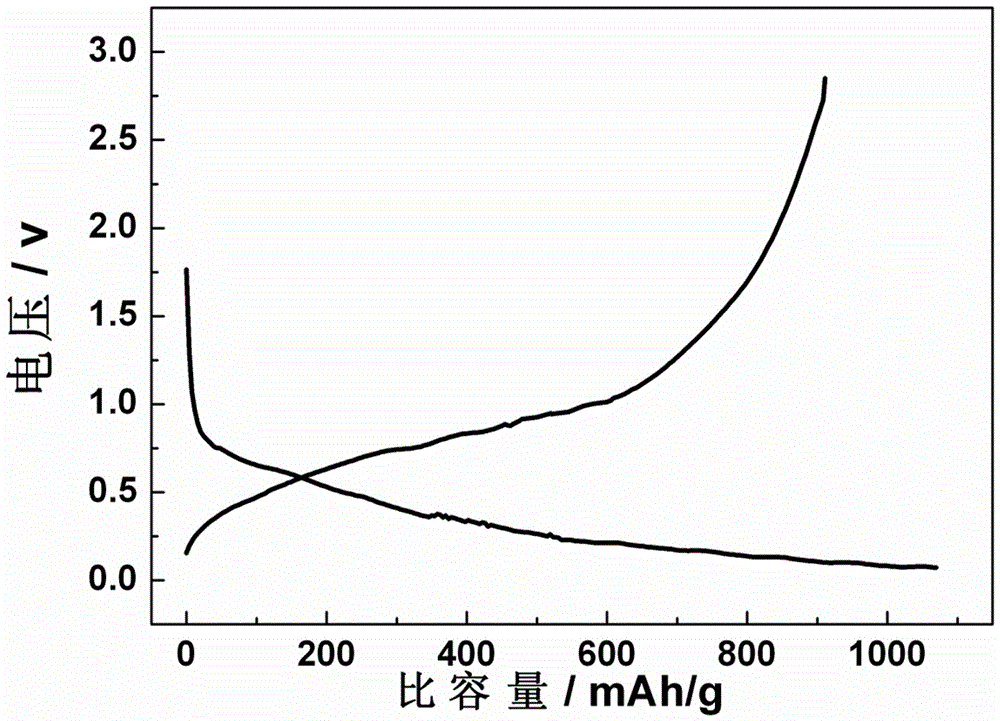

Embodiment 1

[0020] The GaN target with a purity of 99.99% and the copper foil are respectively placed in the sputtering chamber, the distance between the target and the substrate D=7cm; the cavity is evacuated to V≥1×10 -7 Torr and heat the substrate to 600°C; use magnetron sputtering to bombard the target to deposit and grow GaN on the metal substrate. Reactive gas N 2 Flow rate F=20sccm, working pressure P=100mTorr; sputtering power W=200w, deposition time 120mins. The prepared sample was characterized by SEM, figure 1 It can be seen that the sample is nanoparticles with an average size of about 40nm. The material obtained in Example 1 was made into a button battery according to the following method: the prepared GaN / Cu was cut into a disc with a diameter of 14 mm, and vacuum dried at 120° C. for 12 h. Lithium metal sheet is used as the counter electrode, Celgard membrane is used as the separator, and LiPF is dissolved 6 (1mol / L) EC+DEC (volume ratio 1:1) solution is the electrolyte, ass...

Embodiment 2

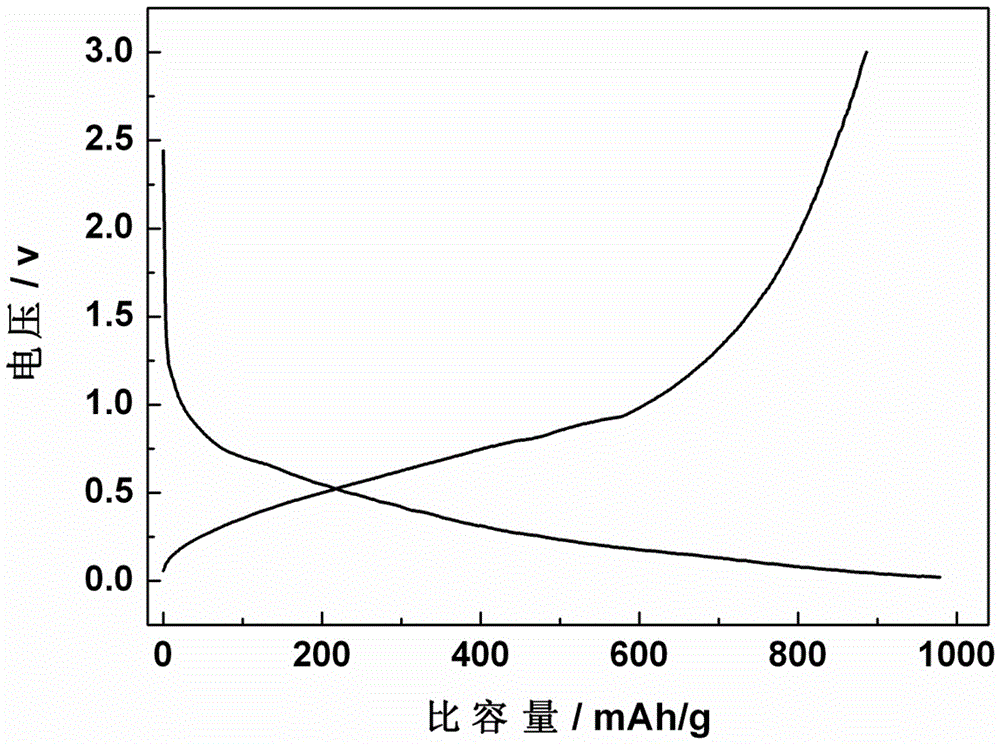

[0022] The GaN target with a purity of 99.99% and the foamed nickel are respectively placed in the sputtering chamber, the distance between the target and the substrate D=7cm; the chamber is evacuated to V≥1×10 -7 Torr and heat the substrate to 600°C; use magnetron sputtering to bombard the target to deposit and grow GaN on the metal substrate. Reactive gas N 2 Flow rate F=20sccm, working pressure P=100mTorr; sputtering power W=200w, deposition time 80mins. The material obtained in Example 2 was prepared into a button battery according to the steps in Example 1 and its electrochemical performance was studied. Such as image 3 As shown, the first charge and discharge capacities of the GaN prepared in Example 2 as the negative electrode of the lithium ion battery are 888 and 980 mAh / g, respectively.

Embodiment 3

[0024] Place the GaN target with a purity of 99.99% and the foamed copper with pre-deposited graphene in the sputtering chamber. The distance between the target and the substrate is D=7cm; the chamber is evacuated to V≥1×10 -7 Torr and heat the substrate to 600°C; use magnetron sputtering to bombard the target to deposit and grow GaN on the metal substrate. Reactive gas N 2 Flow rate F=20sccm, working pressure P=100mTorr; sputtering power W=200w, deposition time 30mins. The material obtained in Example 2 was prepared into a button battery according to the steps in Example 1 and its electrochemical performance was studied. Such as image 3 As shown, the first charge and discharge capacities of the GaN prepared in Example 2 as the negative electrode of a lithium ion battery are 913 and 955 mAh / g, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com