Loaded graphite phase carbonized nitrogen composite material as well as preparation method and application thereof

A composite material, graphite phase technology, applied in a new composite nanocatalyst and its application in the reduction of p-nitrophenol, can solve the problem of difficulty in obtaining highly dispersed and stable precious metal nanoparticles and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Dissolve 2 g of melamine in 80 ml of deionized water, and heat to 80° C. until completely dissolved to form a uniform and transparent solution A.

[0032] 2) Add 1.5ml of concentrated hydrochloric acid with a concentration of 30wt% into solution A, stir for 30 minutes and mix evenly to form mixed solution B.

[0033] 3) Stir the above mixed solution at a constant temperature of 80° C. until all the white solids are precipitated, and grind it into powder A.

[0034] 4) Place the obtained white powder sample A in a 50ml crucible, place it in a muffle furnace and heat it to 500°C, heat and condense for 2 hours, place it at 80°C for a certain period of time, take it out, and cool it down to room temperature naturally After that, the light yellow product obtained is porous graphite phase nitrogen carbide.

Embodiment 2

[0036] (1) Dissolve 2 g of melamine in 80 ml of deionized water, and heat to 80° C. until completely dissolved to form a uniform and transparent solution A.

[0037] (2) Add 1.5ml of concentrated hydrochloric acid with a concentration of 30wt% into solution A, stir for 30 minutes and mix evenly to form mixed solution B.

[0038] (3) Stir the above mixed solution at a constant temperature of 80° C. until all the white solid is precipitated, and grind it into powder A.

[0039] (4) Place the obtained white powder sample A in a 50ml crucible, place it in a muffle furnace and heat it to 500°C, heat and condense for 2 hours, place it at 80°C for a certain period of time, take it out, and cool it naturally to After room temperature, the light yellow product is porous graphite phase nitrogen carbide.

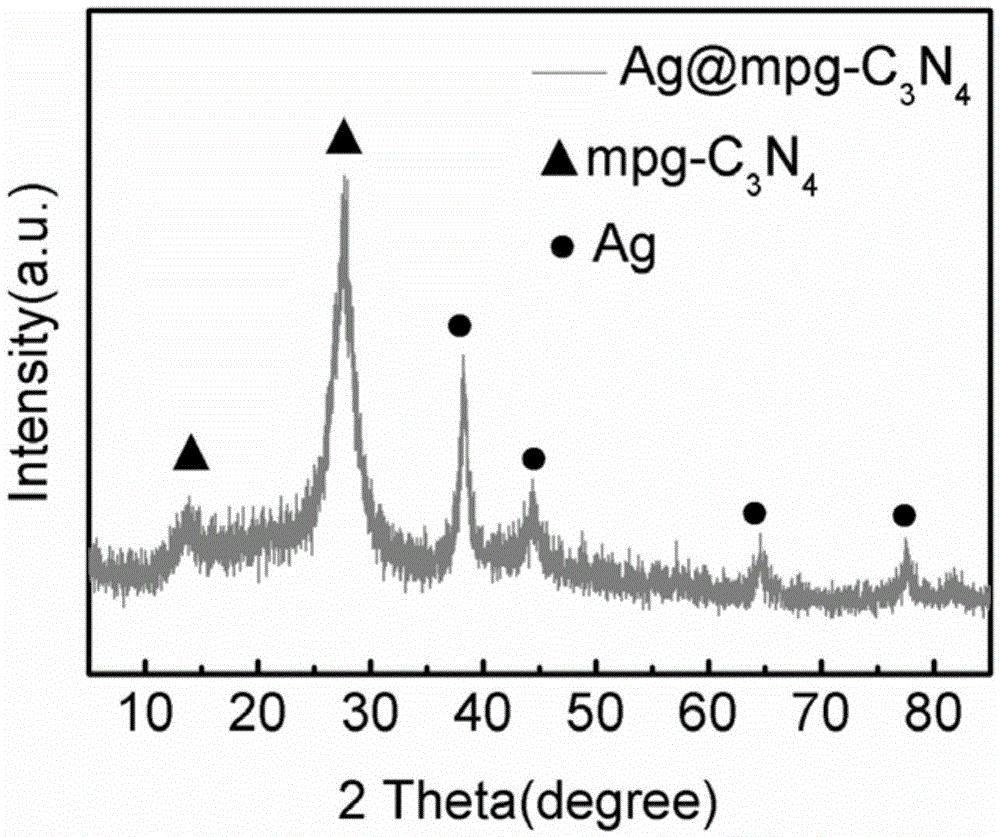

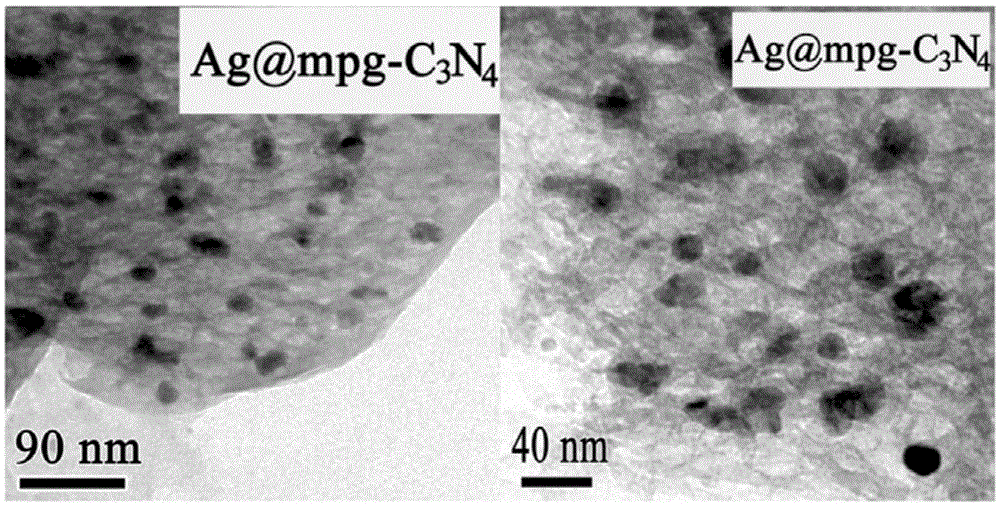

[0040] (5) With the porous graphite phase nitrogen carbide (mpg-C obtained in the above steps 3 N 4 ) as a template, 100mg of mpg-C 3 N 4 Add it into a mixed solution of 20ml of eth...

Embodiment 3

[0048] (1) Dissolve 2 g of melamine in 80 ml of deionized water, and heat to 80° C. until completely dissolved to form a uniform and transparent solution A.

[0049] (2) Add 1.5ml of concentrated hydrochloric acid with a concentration of 30wt% into solution A, stir for 30 minutes and mix evenly to form mixed solution B.

[0050] (3) Stir the above mixed solution at a constant temperature of 80° C. until all the white solid is precipitated, and grind it into powder A.

[0051] (4) Place the obtained white powder sample A in a 50ml crucible, place it in a muffle furnace and heat it to 500°C, heat and condense for 2 hours, place it at 80°C for a certain period of time, take it out, and cool it naturally to After room temperature, the light yellow product is porous graphite phase nitrogen carbide.

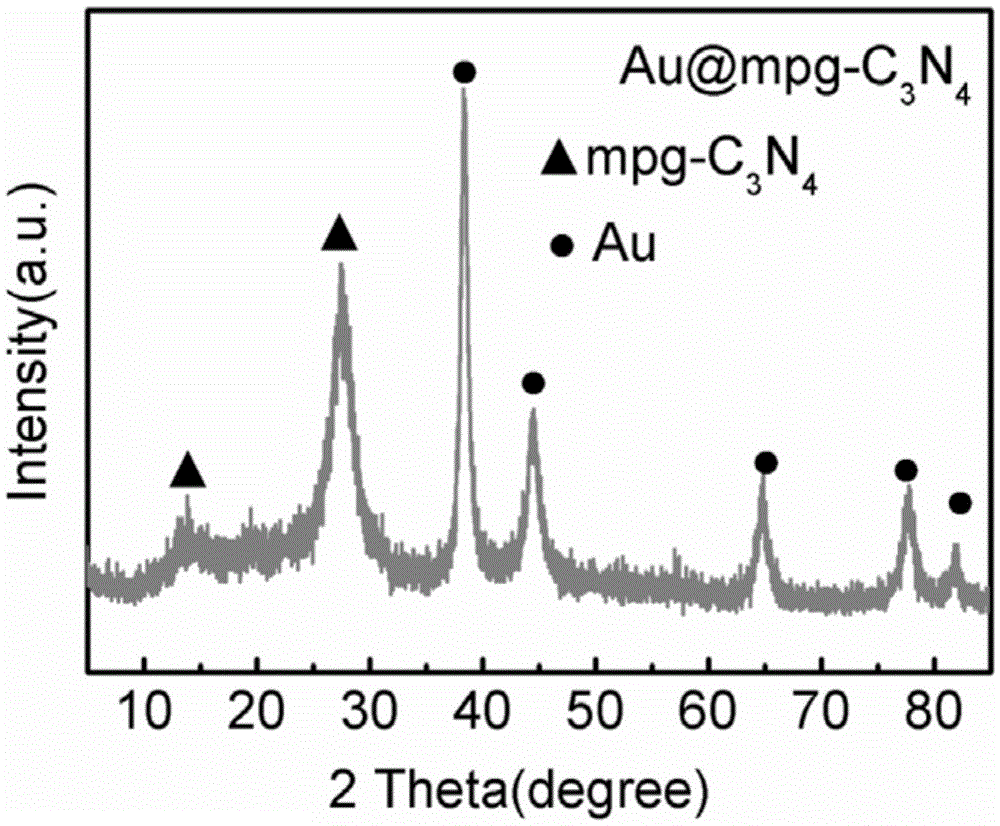

[0052] (5) With the porous graphite phase nitrogen carbide (mpg-C obtained in the above steps 3 N 4 ) as a template, 100mg of mpg-C 3 N 4 Add it to 20ml of isopropanol and water m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com