Graphene dispersant and its application

A graphene and dispersion technology, applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of graphene material chemical composition and physical morphology changes, ineffective effects, non-universal, etc., to achieve beneficial Large-scale implementation, low cost, and the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

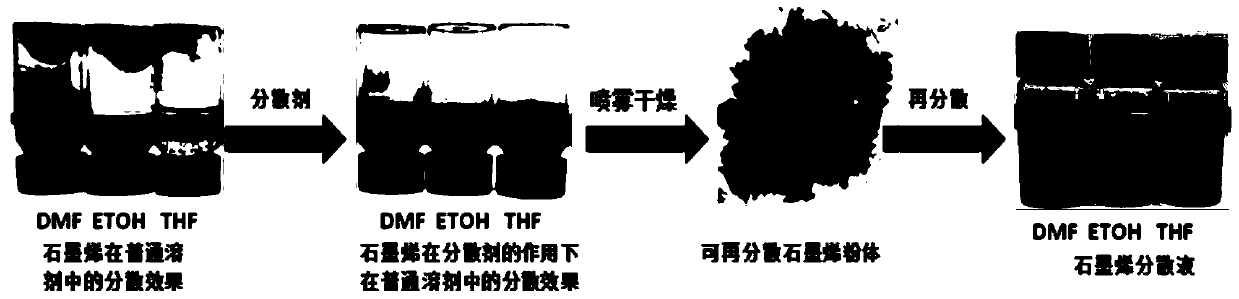

[0055] Another aspect of the present invention also provides a method for preparing a graphene dispersion, which includes: uniformly mixing graphene and the graphene dispersant in a dispersion medium to form a stable dispersion.

[0056] In some embodiments, a graphene dispersion method may include: only dissolving the graphene dispersant and graphene in an organic solvent, thereby forming a stable dispersion. It should be noted that the "dissolved" mentioned here is not understood by those of ordinary skill as dissolved, but should be understood as "incorporated", "dispersed into" or "mixed in", etc. For example, the graphene dispersant and graphene can be added into an organic solvent, and stirred or ultrasonically dispersed, for example, ultrasonically dispersed for more than 1 hour, so as to form a stable dispersion liquid.

[0057] More preferably, the dispersion contains graphene at a concentration of 1 mg / ml-10 mg / ml.

[0058] In the graphene dispersion method, the mol...

Embodiment 1

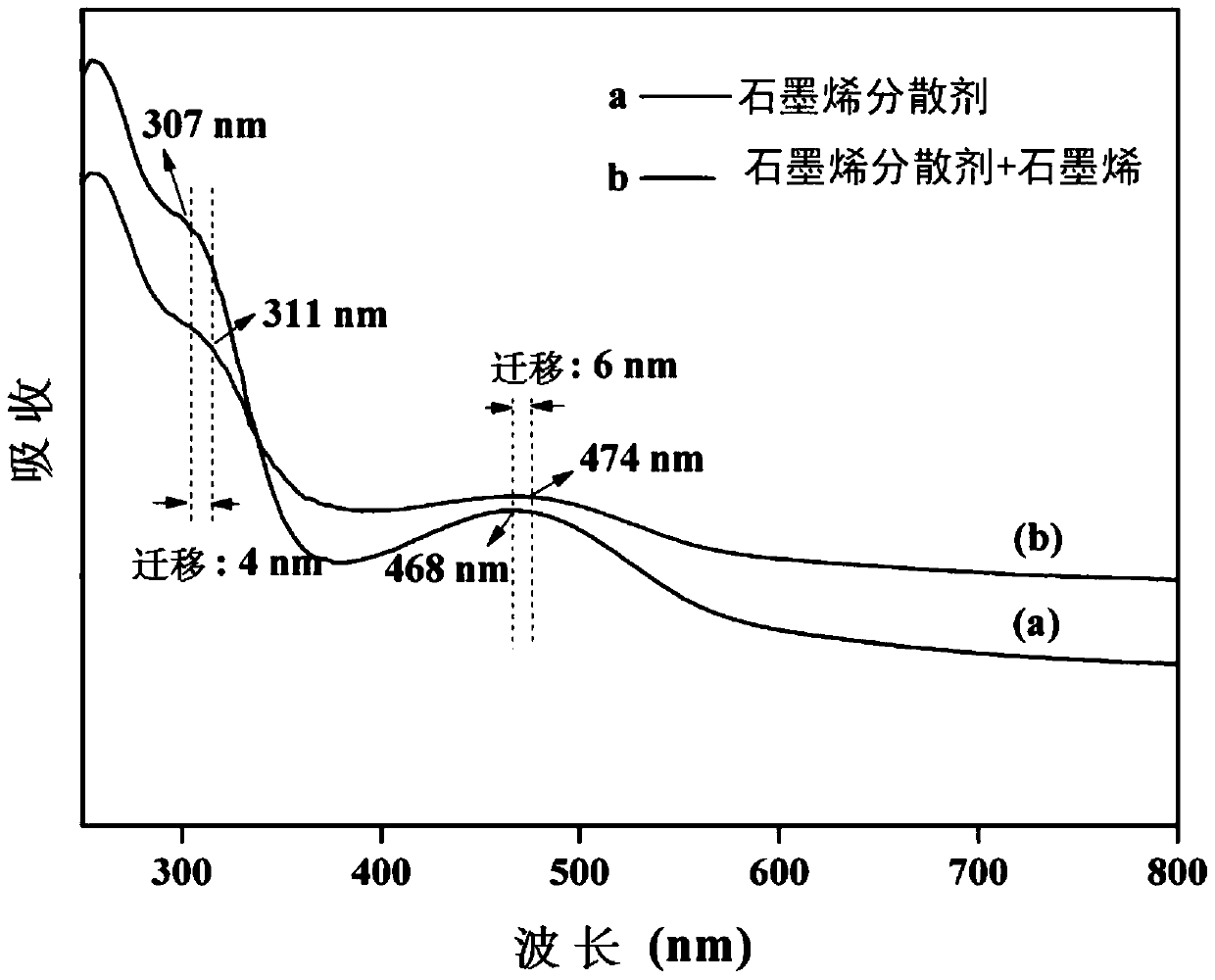

[0075] The synthesis of embodiment 1 aniline trimer and its use in the dispersion of graphene in oily solvent

[0076] Add 2.96g of p-phenylenediamine sulfate, 1.85g of aniline and 50mL of 1M HCl solution into a round-bottomed flask, and place it in an ice-salt bath at -5°C to form a reaction solution A. In addition, 4.5 g of ammonium persulfate was dissolved in 50 mL of HCl solution with a concentration of 1 M to form a reaction solution B, and the solution B was slowly added dropwise to the above reaction solution A at a rate of about 1 drop / second. After the addition was completed, Stirring was continued for 1 h. After the reaction, the product was poured into a Buchner funnel for suction filtration, washed with a 1M HCl solution pre-cooled to 0°C, and then washed with a large amount of deionized water to obtain a dark green solid product. The product was first washed with 10% (mass fraction) ammonia water, and then washed with a large amount of deionized water to finally ...

Embodiment 2

[0083] Embodiment 2. the synthesis of aniline tetramer and its use in graphene oily dispersion

[0084] Weigh 18.5g of aniline dimer in a round bottom flask, add 200ml of acetone and 300ml of HCl with a concentration of 1M, stir and dropwise add 45.65g of ammonium persulfate in an HCl solution with a concentration of 1M in an ice bath, and react for 3 hours Afterwards, filter, wash with 1M ammonia water and distilled water successively to obtain aniline tetramer. The obtained aniline tetramer and graphene slurry were dissolved in tetrahydrofuran in a certain proportion, ultrasonically dispersed for 1 hour, and its dispersion effect in the solution was checked. As shown in Table 3, the aniline tetramer and graphene composite were When the concentration is below 2.5mg / ml, a stable dispersion can be formed in tetrahydrofuran.

[0085] After the dispersion liquid is dried by spray drying, a graphene-dispersant compound can be obtained, and the graphene-dispersant compound is dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com