Quick starting method of waste water treatment system short-cut nitrification denitrification

A wastewater treatment system and short-range nitrification technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of long-term stable operation, strong adaptability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 denitrification microbial preparation

[0029] 1. Cultivation of a single bacterial strain: According to the methods described in CN102465103, CN102465104, CN102465105 and CN102465106, the four bacterial strains FDN-1, FDN-2, DN-3 and SDN-3 were individually cultured to the logarithmic growth phase to obtain a single The seed liquid of the strain.

[0030] 2. Preparation of nitrogen-removing microbial preparations: the seed liquids of the above-mentioned four strains of Arthrobacter FDN-1, Flavobacterium waterii FDN-2, Paracoccus denitrificans DN-3 and Methylobacterium SDN-3 were mixed at a ratio of 1:2. : 8~15:8~15 and 8~15:8~15:2:1 are mixed in two volume ratios, respectively carried out amplified culture in a reactor with a good stirring system, and the concentration of ammonia nitrogen in the culture solution is 200~800mg / L, the mass ratio of carbon to nitrogen is 2:1~4:1, the temperature is 25°C~35°C, the pH value is 6.5~10.0, the ...

Embodiment 2

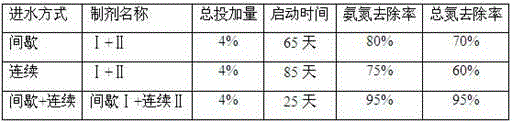

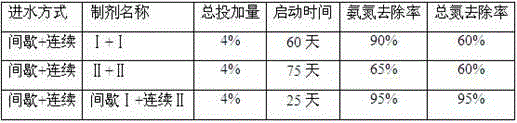

[0033] Use self-prepared wastewater with ammonia nitrogen concentration of 300mg / L and COD concentration of 800mg / L as the test water for short-range nitrification and denitrification start-up test of the reactor. During the start-up process, the pH is controlled at 7.9, the temperature is controlled at 20°C, 1.5~3.0mg / L, the mass ratio of carbon to nitrogen is 4:1. Firstly, 20% of the treated wastewater volume was inoculated with activated sludge for adaptive acclimatization. First run intermittently, stop ventilation after 24 hours of reaction, discharge the supernatant after natural settlement, leave activated sludge, and then fill the reactor with new ammonia-containing wastewater. When the removal rate of ammonia nitrogen is greater than 90%, increase the concentration of ammonia nitrogen in the influent, and the range of each increase is 100mg / L. After 3 days of operation, when the concentration of suspended solids in the supernatant is 80mg / L, add according to the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com