Carbonitriding heat treatment process method

A technology of carbonitriding and process method, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., and can solve the problems of complex heat treatment process and no process specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

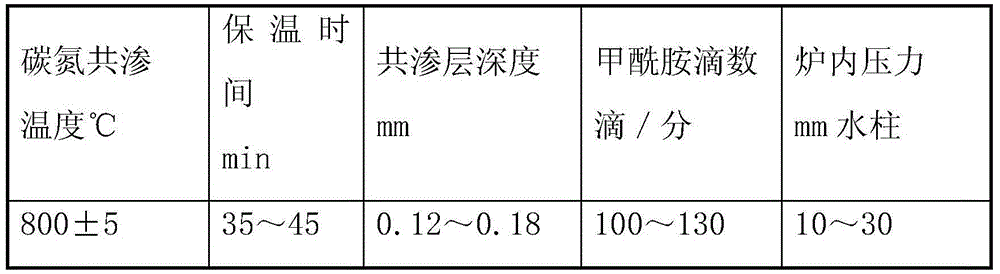

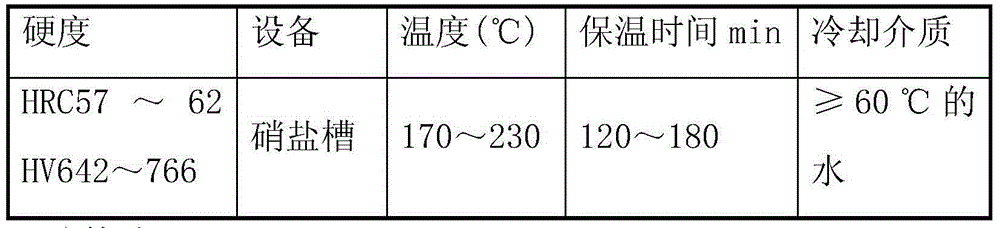

[0013] Best process implementation steps:

[0014] 1 Process material confirmation (see Table 1):

[0015] Table 1 process materials

[0016] serial number

Material

Specification

1

Absolute ethanol (C 2 h 5 Oh)

GB / T678

chemically pure

2

Toluene (C 6 h 5 CH 3 )

GB / T684

chemically pure

3

HB5408

industrial grade

4

HB5408

Industrial Premium

5

GB2367

Industrial Level 2

6

Formamide (HCONH 2 )

---

chemically pure

[0017] 2 Process flow confirmation: parts acceptance → pre-infiltration preparation → carbonitriding → quenching → cleaning → tempering → inspection

[0018] a) Parts acceptance: The parts delivered for carbonitriding are not allowed to have cracks, scratches, burrs, sharp corners, rust, corrosion, paint, oil, dirt and oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com