Seabed medium-voltage direct-current power distribution device

A technology of DC power distribution and DC power, applied in the cooling/ventilation of substations/switchgears, etc., can solve the problems of reducing reliability and stability, aging of components, and high requirements for elastic structure design, so as to improve reliability and stability. , Reduce the requirements of the matching process, the effect of compact electromechanical integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

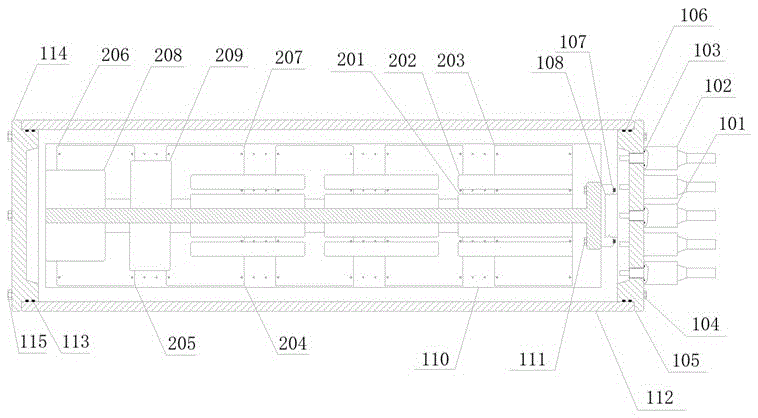

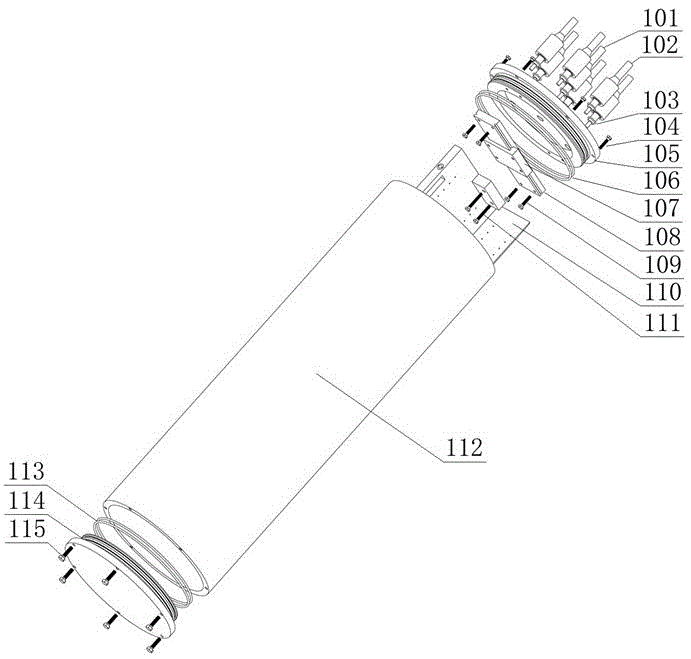

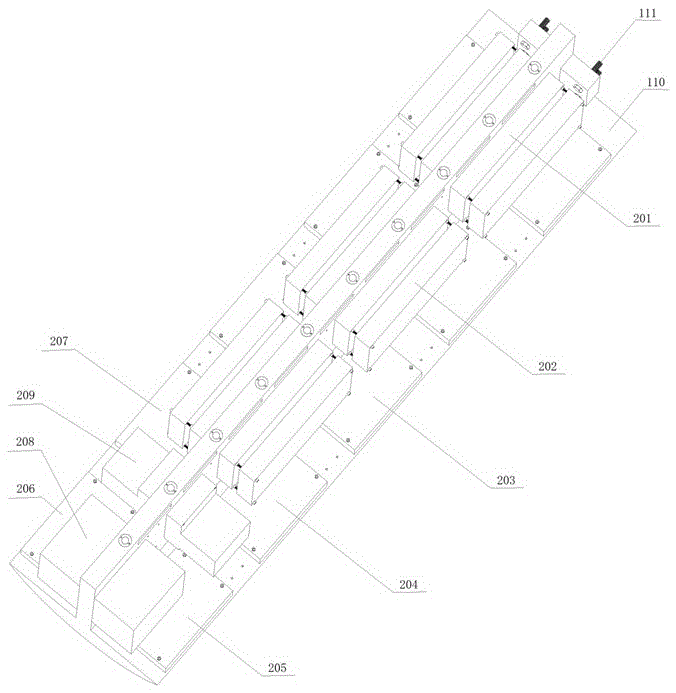

[0026] Example 1: Figure 1-Figure 9 It is the structure and installation method of the pressure-resistant sealed cavity and heat dissipation support of the submarine medium-voltage DC power distribution device. The submarine medium-voltage DC power distribution device includes an internal functional unit and a pressure-resistant sealed cavity, and the internal functional unit is installed in the pressure-resistant sealed cavity: the pressure-resistant sealed cavity mainly includes a front end cover 105, a cylinder Body 112 and rear end cover 114, the first watertight connector 101 and the second watertight connector 102 are installed on the front end cover, and each of the first watertight connector 101 and the second watertight connector 102 has a first An O-shaped sealing ring 103 realizes the sealing with the front end cover 105, the front end cover 105 and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com