Mildew-proof and mildew-removing agent of compound feed and preparation method of mildew-proof and mildew-removing agent

The technology of compound feed and mold remover is applied in the field of feed science, which can solve the problems of poor palatability, single method and high cost of mold inhibitor, and achieve the effects of improving hydrophobic performance, improving adsorption performance and improving adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Preparation method, the steps are as follows:

[0019] 1) After using ferric chloride to modify diatomite and cetylpyridine to modify montmorillonite, then mix the modified diatomite and montmorillonite according to the proportion;

[0020] 2) After mixing sorbic acid, sodium diacetate and propionic acid according to the proportion of the components, they are evenly mixed with the raw materials of step 1) to make them into powder;

[0021] 3) The compound feed anti-mold and mildew-removing agent is added according to 0.5-1% of the total amount of feed each time.

Embodiment 1

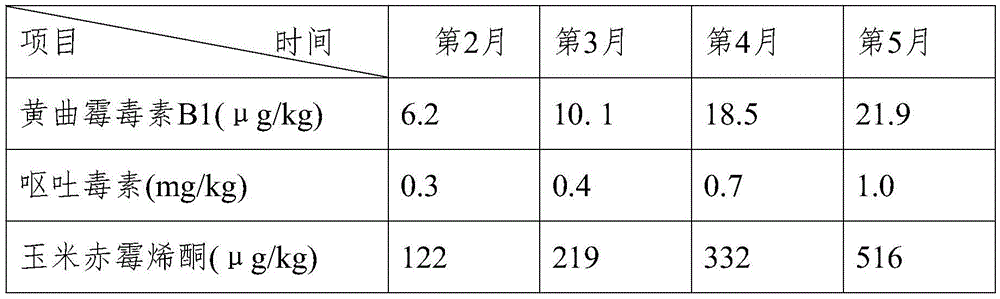

[0023] Raw materials are weighed by weight percentage: 58% of diatomite, 22% of montmorillonite, 6% of sorbic acid, 8% of sodium diacetate, and 6% of propionic acid. Made into powder to achieve the coefficient of variation of mixing uniformity: CV≤5%. The mixed additive is added to the fattening pig compound feed with a water content of 13.9% according to the proportion of 1%, and the coefficient of variation of the mixing uniformity is achieved after mixing: CV≤7%. Store in a cool and dry room, with a shelf life of 3 months in summer. The maximum allowable value of mycotoxins in compound feed for fattening pigs in my country is: aflatoxin B1≤20μg / kg, vomitoxin≤1mg / kg, zearalenone≤500μg / kg kg. The samples were tested for mycotoxins on the 2.3.4.5 month respectively, and the test results are as follows:

[0024]

Embodiment 2

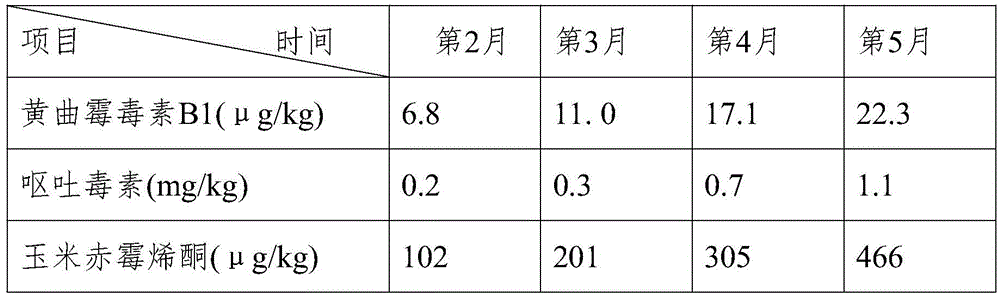

[0026] Raw materials are weighed by weight percentage: 65% of diatomite, 15% of montmorillonite, 5% of sorbic acid, 10% of sodium diacetate, and 5% of propionic acid. Made into powder to achieve the coefficient of variation of mixing uniformity: CV≤5%. The mixed additive is added to the fattening pig compound feed with a water content of 13.9% according to the proportion of 1%, and the coefficient of variation of the mixing uniformity is achieved after mixing: CV≤7%. Store in a cool and dry room, with a shelf life of 3 months in summer. The maximum allowable value of mycotoxins in compound feed for fattening pigs in my country is: aflatoxin B1≤20μg / kg, vomitoxin≤1mg / kg, zearalenone≤500μg / kg kg. The samples were tested for mycotoxins on the 2.3.4.5 month respectively, and the test results are as follows:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com