Preparation method of lignin hierarchical porous carbon material with endellite as template

A lignin-based, multi-level porous technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc. Excellent regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

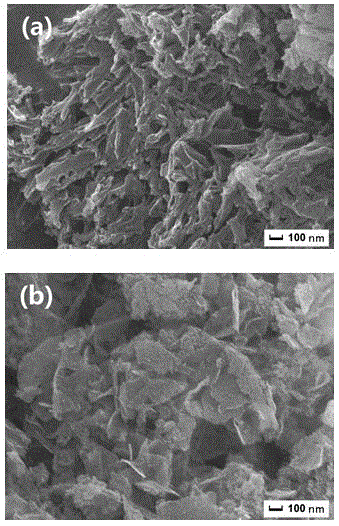

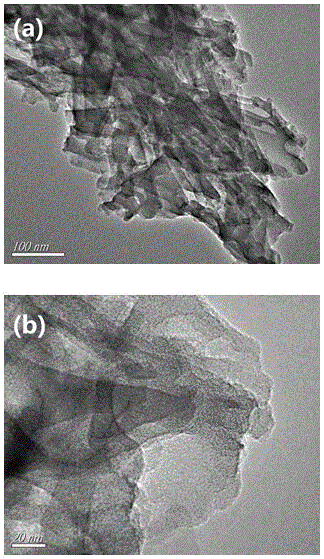

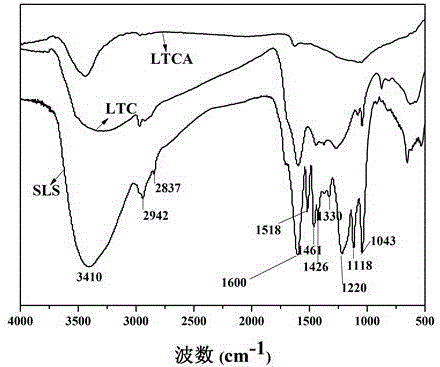

[0041] (1) Preparation of lignin-based template carbon materials

[0042] In the present invention, a lignin-based template carbon material is prepared by a liquid-phase impregnation method. 2 g of halloysite is weighed, added to 100 mL of a hydrochloric acid solution with a concentration of 1 mol / L, heated to 40 ° C, reacted for 1 h, suction filtered, and rinsed with a large amount of distilled water until Neutral, drying, to obtain the halloysite after purification, the halloysite after 2g purification process is mixed with 6g mass fraction as 20% sodium lignosulfonate solution, the mixture is placed statically under negative pressure conditions (-0.1 Mpa) for 2 hours, centrifuge at a high speed of 2000r / min for 1.5 hours to achieve the effect of compact accumulation, then dry the lower layer of solids to constant weight, put them into a porcelain boat after weighing, and place them in a tube furnace. Under the protection of a nitrogen atmosphere, the temperature was raised ...

Embodiment 2

[0046] (1) Preparation of lignin-based template carbon materials

[0047] Prepare lignin-based template carbon materials by liquid-phase impregnation method, weigh 5g of halloysite, add it to 100mL hydrochloric acid solution with a concentration of 4mol / L, heat to 80°C, react for 6h, filter with suction, wash with a large amount of distilled water until neutral , dried to obtain the purified halloysite, mix 2g of the purified halloysite with 10g of sodium lignosulfonate solution with a mass fraction of 40%, and place the mixture under negative pressure conditions (-0.3Mpa) After 4 hours, centrifuge at a high speed of 4000r / min for 2.5 hours to achieve the effect of close packing, then dry the lower layer of solids to constant weight, put them into a porcelain boat after weighing, place them in a tube furnace, and store them in a nitrogen atmosphere. Under the protection of the atmosphere, to 7 o C / min heating rate from room temperature to 600 o C and calcined at this tempera...

Embodiment 3

[0051] (1) Preparation of lignin-based template carbon materials

[0052] Prepare lignin-based template carbon materials by liquid-phase impregnation method, weigh 3g of halloysite, add it to 100mL hydrochloric acid solution with a concentration of 3mol / L, heat to 60°C, react for 4h, filter with suction, rinse with a large amount of distilled water until neutral , dried to obtain the purified halloysite, mix 2g of the purified halloysite with 8g of 30% sodium lignosulfonate solution, and place the mixture under negative pressure conditions (-0.2Mpa) After 3 hours, centrifuge at a high speed of 3000r / min for 2 hours to achieve a close-packed effect, then dry the lower layer of solids to constant weight, put them into a porcelain boat after weighing, place them in a tube furnace, and store them in a nitrogen atmosphere. under the protection of 5 o C / min heating rate from room temperature to 500 o C and calcined at this temperature for 2 h, then cooled to room temperature natur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com