A method of assembling nanoelectronic devices

A kind of electronic device and nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the interconnection manufacturing process of integrated circuits is no longer compatible, and achieve the effect of solving chaos and disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

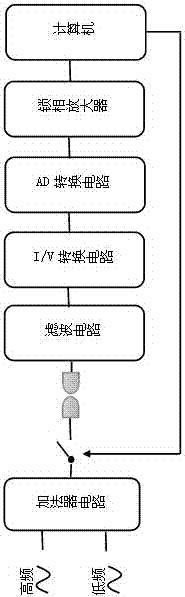

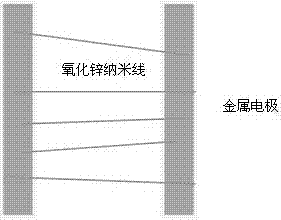

[0020] Step 1: If figure 1 As shown, the circuit system for assembling nanoelectronic devices is built, including high and low frequency AC power supply 1, adder 2, electric key 3, microelectrode pair 4, low-pass filter circuit 5, I / V conversion circuit 6, A / D conversion Circuit 7, lock-in amplifier 8, computer 9, wherein the spacing of microelectrodes is determined as 2 microns according to the size of zinc oxide zinc nanowires;

[0021] Step 2: drop the solution containing zinc oxide nanowires onto the pair of microelectrodes;

[0022] Step 3: Connect the circuit and output 10 6 The high frequency of HZ and the low frequency current of 50HZ, through the computer to observe the change of the electric signal of the circuit, control the closing of the electric key, and disconnect the electric key after five times of waveform changes, so that five zinc oxide nanowires are connected to the microelectrode pair, as in figure 2 shown;

[0023] Step 4: Use high-frequency ultrason...

Embodiment 2

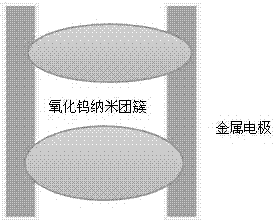

[0025] Step 1: Build a circuit system for assembling nanoelectronic devices, including high and low frequency AC power supply 1, adder 2, electric key 3, microelectrode pair 4, low-pass filter circuit 5, I / V conversion circuit 6, A / D conversion Circuit 7, lock-in amplifier 8, computer 9, wherein the spacing of the microelectrode pair is set as 1 micron;

[0026] Step 2: drop the solution containing tungsten oxide nanoparticles onto the pair of microelectrodes;

[0027] Step 3: Connect the circuit and output 10 5 HZ high-frequency and 30HZ low-frequency current, through the computer to observe the changes in the electrical signal of the circuit to control the closing of the electric key, and disconnect the electric key after two changes in the waveform, so that two zinc oxide nanoparticle clusters are overlapped on the microelectrode pair ,Such as image 3 shown;

[0028] Step 4: Use high-frequency ultrasonic energy to bond the assembled electronic devices.

Embodiment 3

[0030] Step 1: Build a circuit system for assembling nanoelectronic devices, including high and low frequency AC power supply 1, adder 2, electric key 3, microelectrode pair 4, low-pass filter circuit 5, I / V conversion circuit 6, A / D conversion Circuit 7, lock-in amplifier 8, computer 9, wherein the spacing of the microelectrode pairs is determined as 2 microns;

[0031] Step 2: drop the solution containing carbon nanotubes onto the pair of microelectrodes;

[0032] Step 3: Connect the circuit and output 10 7 The high frequency of HZ and the low frequency current of 50HZ, through the computer to observe the change of the electric signal of the circuit, control the closing of the electric key, and disconnect the electric key after the waveform changes, so that a single carbon nanotube is connected to the microelectrode pair;

[0033] Step 4: Use high-frequency ultrasonic energy to bond the assembled electronic devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com