A kind of tungsten bronze nano short rod particles catalyzed and doped by variable valence metal and its preparation method

A variable-valence metal and tungsten bronze technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problem that the heat shielding effect is not optimal, and achieve excellent light-to-heat conversion performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Preparation of Fe 0.1 -Cs 0.32 WO 3 Hexagonal cesium tungsten bronze nanorod particles

[0068] ①Weigh 6.3503g of sodium tungstate, add 30ml of deionized water, fully dissolve, and quickly add 5mol / L hydrochloric acid under stirring conditions to make the pH ≤ 1, after stirring for 30min, milky yellow flocculent tungsten Acid colloidal suspension, after suction filtration, to obtain milky yellow solid colloidal tungstic acid with a certain volume; add solid colloidal tungstic acid to 120ml deionized water, stir evenly under the condition of ultrasonic vibration, and make it redisperse into a suspension solution, continue to filter, repeat three times; then use 120ml of absolute ethanol to repeat the above operation, filter three times, take out the obtained massive gel and add an appropriate amount of absolute ethanol to make the total volume 77ml, stir and redisperse under the condition of ultrasonic vibration Suspension, obtain solid colloidal tungstic acid ethanol...

Embodiment 2

[0073] Preparation V 0.1 -Cs 0.32 WO 3 nanorod particles

[0074] ①Preparation of solid colloidal ethanol tungstate suspension: same as step ① in Example 1

[0075] ②Preparation of reaction precursor

[0076] Weigh 0.6g of cesium sulfate, add it to 40ml solid colloidal tungstate ethanol dispersion, then measure and add 70ml of acetylacetone, add 8.356g of oxalic acid, 1g of P123 inducer, and finally add 0.163g of vanadyl sulfate, stir 2h, obtain the reaction precursor;

[0077] ③Powder synthesis, washing and drying

[0078] The reaction precursor solution was transferred into a 200ml autoclave, and reacted continuously at 190°C for 72h. The precipitate after the reaction was washed with water and alcohol for 3 times, and after centrifugation, it was dried at 60°C for 10h. According to XRD and Judging by EDS, the synthesized blue powder is V-doped V 0.1 -Cs 0.32 WO 3 Hexagonal Cesium Tungsten Bronze.

Embodiment 3

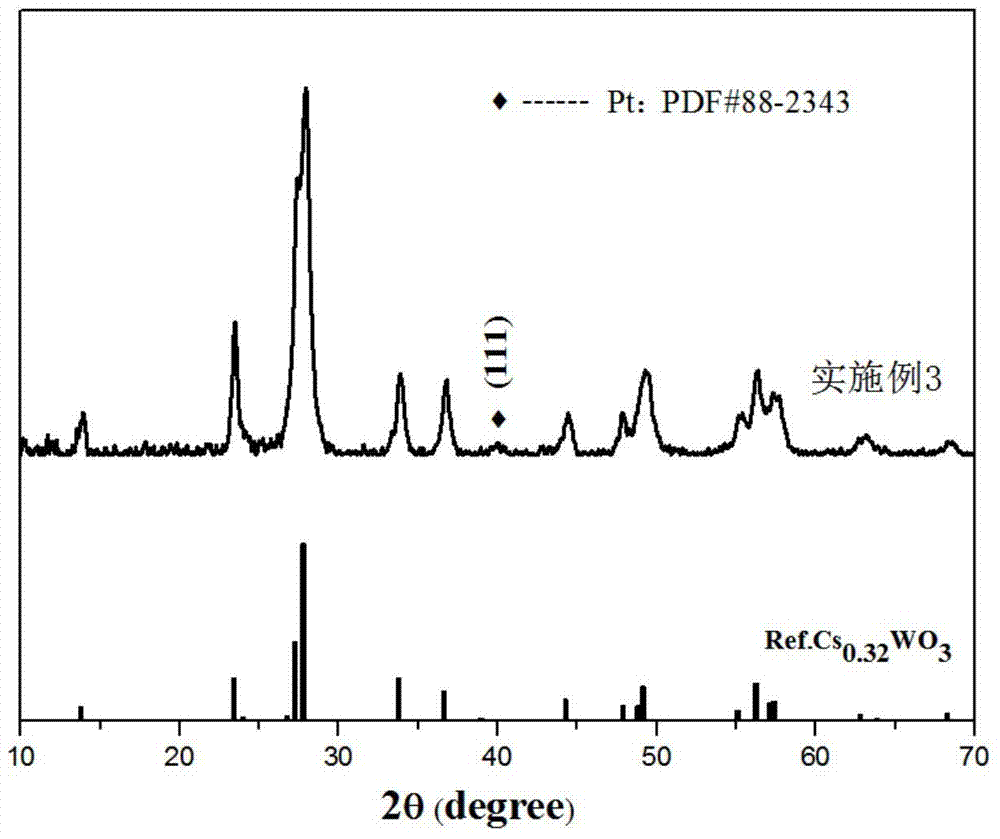

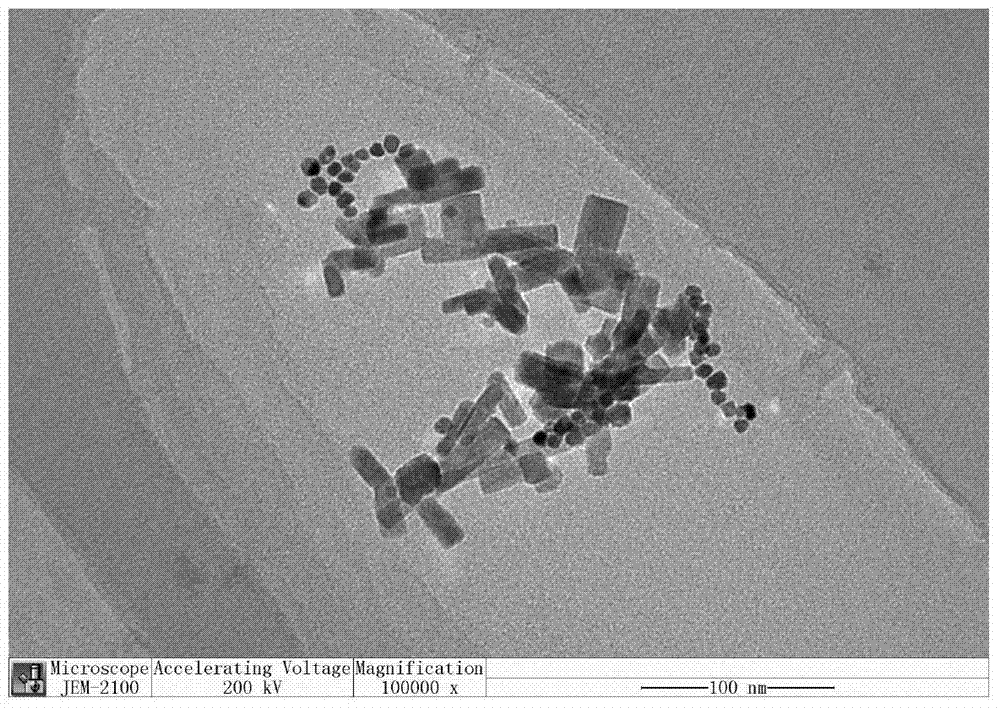

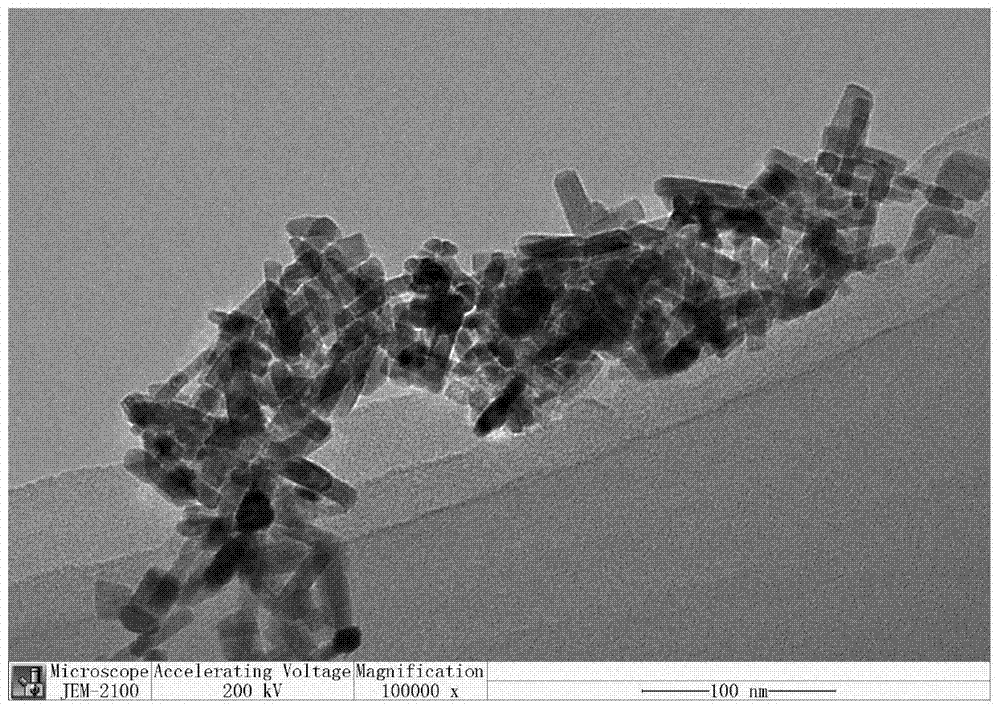

[0080] Preparation of Pt 0.1 -Cs 0.32 WO 3 nanorod particles

[0081] ①Preparation of solid colloidal ethanol tungstate suspension: same as step ① in Example 1

[0082] ② Preparation of reaction precursor solution and powder synthesis

[0083] Weigh 0.6g of cesium sulfate, add it to 40ml of solid colloidal tungstic acid ethanol dispersion, then measure and add 65ml of absolute ethanol, add 5.3721g of sorbic acid, 1g of P123 inducer, and finally add 0.193mol / L of chlorine Platinic acid aqueous solution 5ml, stirred for 2h to obtain the reaction precursor; transfer the reaction precursor into a 200ml autoclave, react continuously at 190°C for 72h, wash the reacted precipitate with water and alcohol for 3 times, and centrifuge Finally, it was dried at 60°C for 10 h. Judging by XRD and EDS, the synthesized blue powder was Pt-doped Pt 0.1 -Cs 0.32 WO 3 Hexagonal Cesium Tungsten Bronze.

[0084] The XRD spectrum of the synthesized Pt-doped cesium tungsten bronze powder is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com