Combined type multi-stage biological aerated filter and wastewater treatment process based on same

A technology of biological aerated filter and biological filter, which is applied in the directions of multi-stage water treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. Nitrification, biological aerated filter is easy to clog and other problems, to achieve the effect of high treatment effect, prolong the backwash cycle, and reduce the probability of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

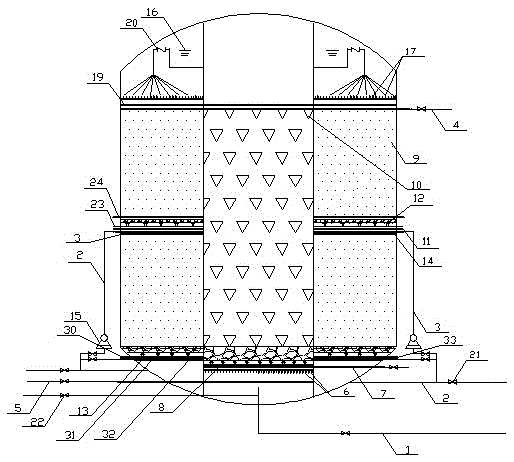

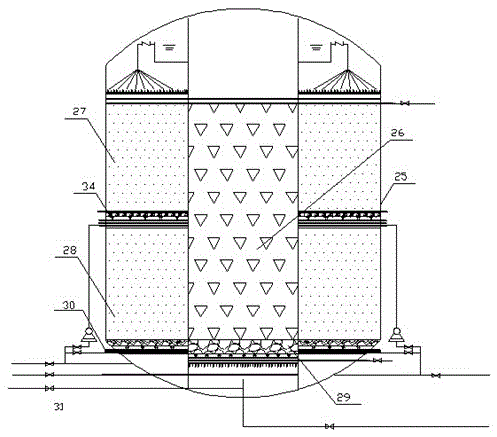

[0033] A compound double-stage biological aerated filter, comprising a tank-shaped filter body 25, and a water inlet pipe 1 and an outlet pipe 21 arranged at the bottom end of the tank-shaped filter body 25, the center of the bottom end of the tank-shaped filter body 25 is provided with Cylindrical primary biological aerated filter 26, the primary biological aerated filter 26 divides the filter body 25 into a secondary biological aerated filter 27 and a tertiary biological aerated filter 28 from top to bottom; the cylindrical primary biological aerated filter The diameter ratio of the gas biofilter to the tank-shaped filter body is 1:2;

[0034] The first water distribution device 6, the first aeration device 8, the first perforated plate 13 and the first crushed stone supporting layer 29 are sequentially arranged between the primary biological aerated filter tank 26 and the water inlet pipe 1 from bottom to top; The first perforated plate 13 and the first crushed stone suppor...

Embodiment 2

[0045] In this example, the composite double-stage biological aerated filter obtained in Example 1 is used to treat a certain rural domestic sewage. The COD concentration of the sewage is 240 mg / L, the ammonia nitrogen concentration is 32.1 mg / L, and the nitrate nitrogen concentration is 10 mg / l. .

[0046] The treatment process is as follows:

[0047] A) The simulated laboratory water to be treated is evenly sprinkled into the primary biological aerated filter 26 through the water inlet pipe 1 through the first water inlet device 6, and the inlet water passes through the suspended packing in the central filter column 10 in reverse direction and is exposed at the same time. The air passes through the overflow weir 16 and the check valve 20 into the second-stage biological aerated filter 27 with finer fillers, and then runs downward to the third-stage biological aerated filter 28, and finally passes through the outlet pipe 21 by gravity. discharge;

[0048] Wherein, the disso...

Embodiment 3

[0054] In this embodiment, a compound multi-stage biological aerated filter is used to treat a certain rural domestic sewage. The influent COD concentration is 200-300mg / L, the ammonia nitrogen concentration is 25-40mg / L, the TN concentration is 40-60mg / L, and the TP concentration It is 4-7mg / L, 10-20mg / L phthalic acid lipids, and the turbidity is 7-10NTU.

[0055] The running time of sewage in this example is 6 months, the treated water volume is 2.5L / h, the primary biological aerated filter is backwashed every 7 days, and the secondary biological aerated filter is backwashed every 15 days. The removal rate of organic matter, ammonia nitrogen and total nitrogen can reach more than 85%, the removal rate of TP is about 80%, the removal rate of phthalic acid lipids is more than 60%, and the removal rate of turbidity can reach more than 90%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com