Pig protoheme extraction method

An extraction method, heme technology, applied in the direction of organic chemistry, etc., can solve the problems of co-production of other products, long production cycle, high cost, etc., and achieve the effect of omitting the steps of cracking and dissolving, saving production cost and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

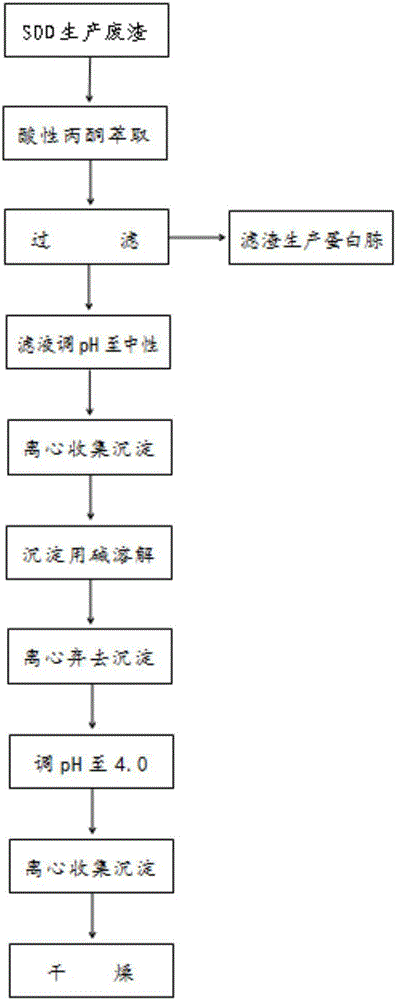

Method used

Image

Examples

Embodiment 1

[0052] Step 1, take by weighing the production SOD waste residue of 100kg;

[0053] Step 2, add 200L of acidic acetone, homogenate, the volume ratio of concentrated hydrochloric acid and acetone in the acidic acetone is 2: 100, the concentration of hydrochloric acid in the described concentrated hydrochloric acid is 12mol / L;

[0054] Step 3, collecting the filtrate by plate and frame filtration;

[0055] Step 4, the filter residue repeats steps 2-3 once, merges the filtrate twice, and collects the filter residue for producing peptone;

[0056] Step 5, adjust pH to neutrality with sodium acetate;

[0057] Step 6, centrifuge and collect about 16 kg of sediment in a three-legged centrifuge;

[0058] Step 7, dissolve with 80kg0.1mol / L NaOH solution;

[0059] Step 8, centrifuging in a tubular centrifuge to discard the precipitate;

[0060] Step 9, adjust the pH to 4.0 with 0.1mol / L hydrochloric acid;

[0061] Step 10, centrifuging to collect the precipitate;

[0062] Step 11,...

Embodiment 2

[0065] Step 1, take by weighing the production SOD waste residue of 300kg;

[0066] Step 2, add 600L of acidic acetone, homogenate, the volume ratio of concentrated hydrochloric acid and acetone in the acidic acetone is 2: 100, the concentration of hydrochloric acid in the described concentrated hydrochloric acid is 12mol / L;

[0067] Step 3, collecting the filtrate by plate and frame filtration;

[0068] Step 4, the filter residue repeats steps 2-3 once, merges the filtrate twice, and collects the filter residue for producing peptone;

[0069] Step 5, adjust pH to neutrality with sodium acetate;

[0070] Step 6, centrifuge and collect about 46.5kg of sediment in a three-legged centrifuge;

[0071] Step 7, dissolve with 80kg0.1mol / L NaOH solution;

[0072] Step 8, centrifuging in a tubular centrifuge to discard the precipitate;

[0073] Step 9, adjust the pH to 4.0 with 0.1mol / L hydrochloric acid;

[0074] Step 10, centrifuging to collect the precipitate;

[0075] Step 11...

Embodiment 3

[0078] Step 1, take by weighing the production SOD waste residue of 500kg;

[0079] Step 2, add 1T of acidic acetone, homogenate, the volume ratio of concentrated hydrochloric acid to acetone in the acidic acetone is 2: 100, and the concentration of hydrochloric acid in the concentrated hydrochloric acid is 12mol / L;

[0080] Step 3, collecting the filtrate by plate and frame filtration;

[0081] Step 4, the filter residue repeats steps 2-3 once, merges the filtrate twice, and collects the filter residue for producing peptone;

[0082] Step 5, adjust pH to neutrality with sodium acetate;

[0083] Step 6, about 70kg of sediment is collected by centrifugation in a three-legged centrifuge;

[0084] Step 7, dissolve with 350kg0.1mol / L NaOH solution;

[0085] Step 8, centrifuging in a tubular centrifuge to discard the precipitate;

[0086] Step 9, adjust the pH value to 4.0 with 0.1mol / L hydrochloric acid;

[0087] Step 10, centrifuging to collect the precipitate;

[0088] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com