Functional protective surface material having excellent adhesion performance and preparation method thereof

A surface material, ethyl technology, applied in the field of materials, can solve problems such as unpublished reports, and achieve the effect of improving protective performance, wide application range, and strong chemical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

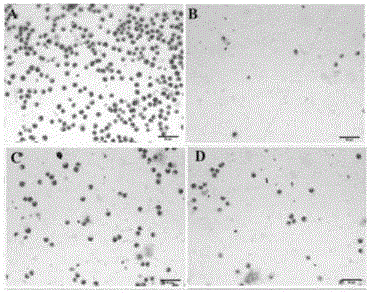

Image

Examples

Embodiment 1

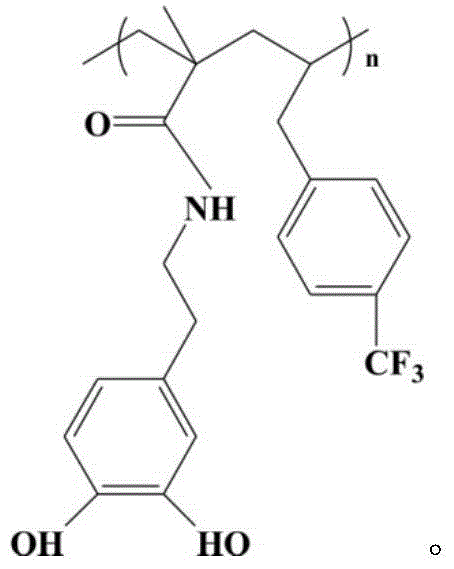

[0026] N-(3,4-dihydroxyphenyl) ethyl-methacrylamide copolymer, the structural formula of the copolymer is:

[0027]

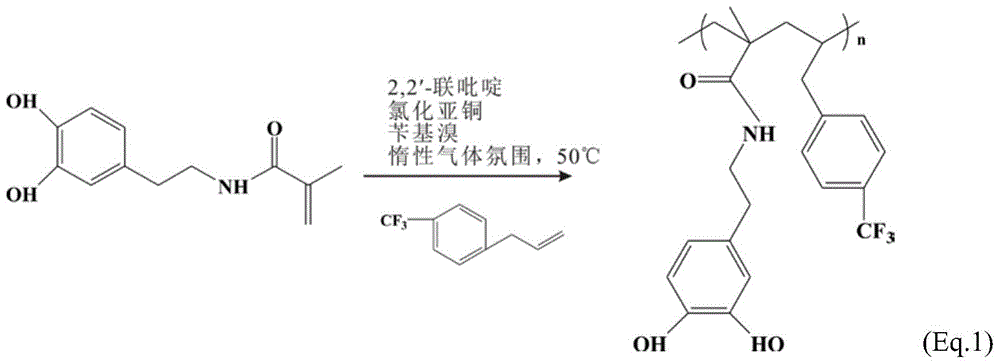

[0028] N-(3,4-dihydroxyphenyl) ethyl-methacrylamide copolymer is prepared by the following method: ① In parts by weight, weigh 3 parts of 1-allyl-4-(tri Fluoromethyl)benzene, 0.2 parts of N-(3,4-dihydroxyphenyl)ethyl-methacrylamide, 0.03 parts of cuprous chloride, 0.4 parts of 2,2′-bipyridyl, 0.03 parts of benzyl bromide ; ② take the toluene that has been dried in advance, and pass it into argon for 15 minutes; add the materials prepared in step ① into the toluene, and stir and react for 6 hours under the protection of argon at a temperature of 50 ° C; the reaction equation is as Eq .1 shown. ③ Evaporate the solution after the reaction in step ②, and then wash it with methanol and acetone for 4 times to remove the solvent attached to the surface of the precipitate to obtain the product. Each part by weight is 10 g.

[0029]

[0030] The reaction mechan...

Embodiment 2

[0033] The difference from Example 1 is that the N-(3,4-dihydroxyphenyl) ethyl-methacrylamide copolymer is prepared by the following method: ① In parts by weight, weigh 4 parts of 1- Allyl-4-(trifluoromethyl)benzene, 0.3 parts of N-(3,4-dihydroxyphenyl)ethyl-methacrylamide, 0.06 parts of cuprous chloride, 0.1 parts of 2,2′- Bipyridine, 0.04 parts of benzyl bromide; ②Take the pre-dried toluene and blow it with argon for 5 minutes; add the materials prepared in step ① into toluene, and stir for 8 hours under the protection of an inert gas atmosphere and at a temperature of 60°C . ③ Evaporate the solution after the reaction in step ②, and then wash it twice with methanol and acetone respectively to remove the solvent attached to the surface of the precipitate to obtain the product.

[0034] The preparation method of the functional protective surface material with good adhesion properties comprises the following steps: ① Weigh an appropriate amount of N-(3,4-dihydroxyphenyl) ethy...

Embodiment 3

[0036] The difference from Example 1 is that the N-(3,4-dihydroxyphenyl) ethyl-methacrylamide copolymer is prepared by the following method: ① In parts by weight, weigh 5 parts of 1- Allyl-4-(trifluoromethyl)benzene, 0.4 parts of N-(3,4-dihydroxyphenyl)ethyl-methacrylamide, 0.01 parts of cuprous chloride, 0.2 parts of 2,2′- Bipyridine, 0.05 parts of benzyl bromide; ② Take the pre-dried toluene and blow it with argon for 10 minutes; add the materials prepared in step ① to toluene, and stir for 1 hour under the protection of an inert gas atmosphere and at a temperature of 70°C . ③ Evaporate the solution after the reaction in step ②, and then wash it three times with methanol and acetone respectively to remove the solvent attached to the surface of the precipitate to obtain the product.

[0037] The preparation method of the functional protective surface material with good adhesion properties comprises the following steps: ① Weigh an appropriate amount of N-(3,4-dihydroxyphenyl)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com