Incombustible dual-component polyurethane foam sealant, preparation method thereof, and canned sealant

A technology of two-component polyurethane and foam caulking agent, which is applied in its preparation and the field of polyurethane-containing caulking agent, which can solve problems such as propellant explosion, and achieve the effect of fast curing speed and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Two-component polyurethane non-combustible grade foam caulk

[0034] The caulking agent is composed of component A and component B. The preparation of component A: take polyester polyol SKR-240B (manufactured by Skerui Polyurethane Material Co., Ltd., hydroxyl value 240±10) at a room temperature of 20°C 100 parts by mass, 30 parts by mass of fluorodichloroethane, 15 parts by mass of DMMP, 25 parts by mass of TCEP, 2 parts by mass of silicone oil, 10.6 parts by mass of catalyst PC-4, 0.9 parts by mass of catalyst DMP-30, 0.3 parts by mass of pentamethyldiethylenetriamine After mixing at high speed for 1 minute at 1500 rpm, 80 parts by mass of potassium silicate (solid content above 98%) and 13 parts by mass of chlorinated paraffin were added, and stirred at high speed for 30 minutes.

[0035] B component: isocyanate PM-200.

Embodiment 2

[0036] Example 2: Caulk in a Jar

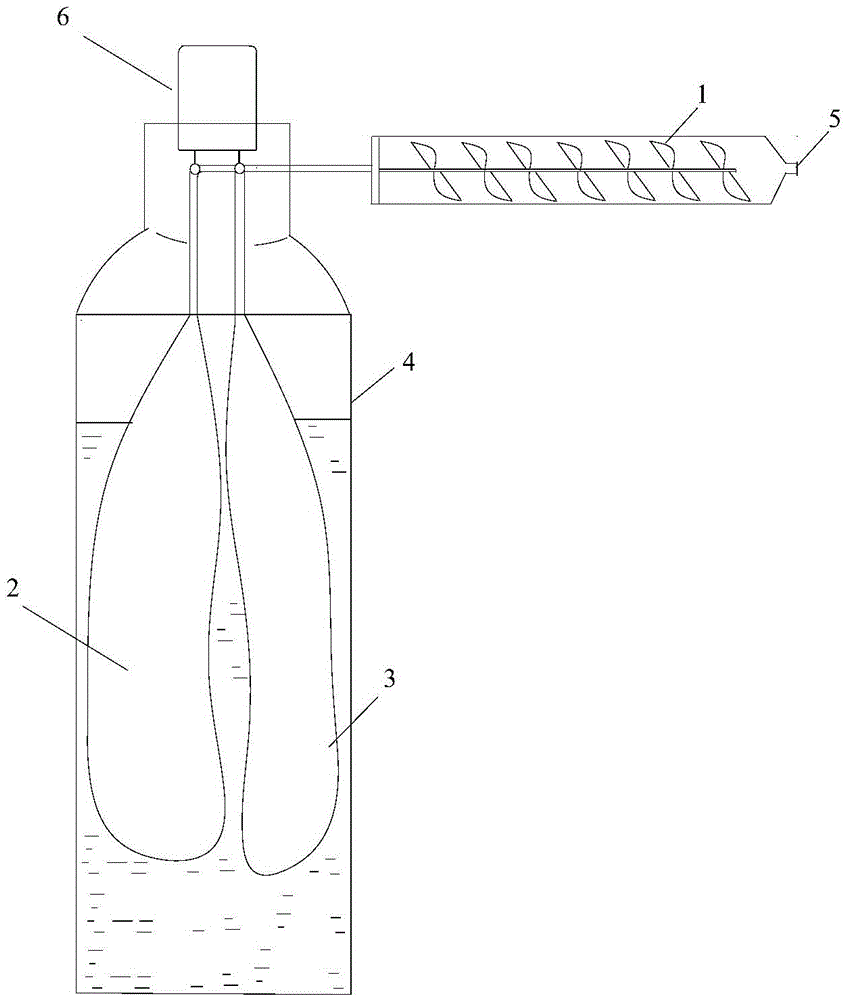

[0037] For the tank structure used see figure 1 .

[0038] Put the caulking agent prepared in Example 1 in a 900mL metal tank 4 (aluminum alloy tank), put A component in A capsule 2, put B component in B capsule 3, and connect the outlets of A capsule and B capsule to the outlet pipe , the outlet pipeline is provided with a push-type valve 6; 130mL propane butane is installed in the metal tank wall, A capsule and B capsule.

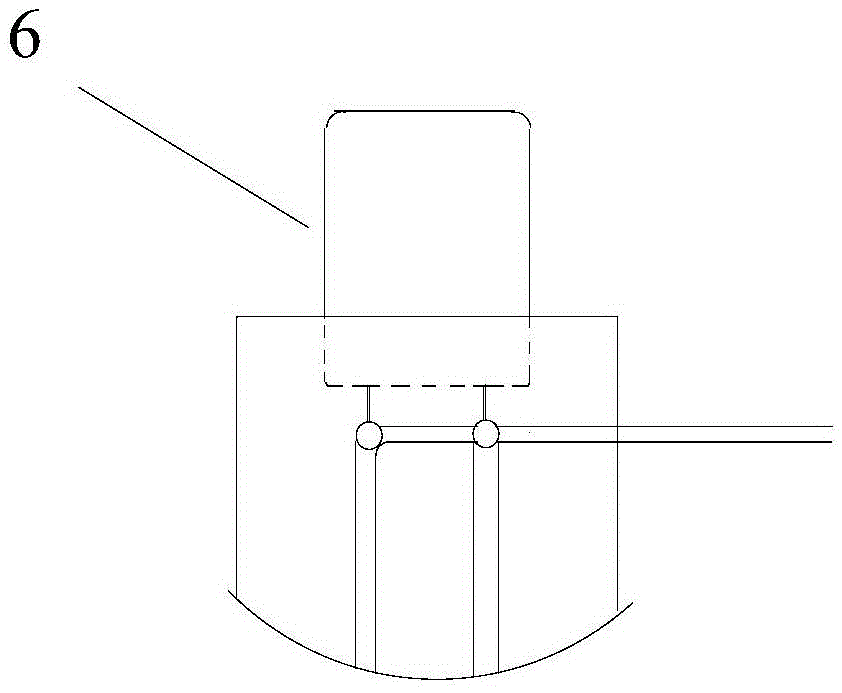

[0039] See figure 2 , two spheres are filled in the outlet of A capsule and the outlet of B capsule respectively in the push-type valve 6 . Press the valve to spray out component A and component B at the same time (propane butane does not spray out, it plays the role of squeezing the capsule).

[0040] Capsule A and Capsule B are soft capsules made of nitrile rubber.

[0041] Wherein, the outlet aperture of capsule A is 1 mm, and the outlet aperture of capsule B is 1.8 mm, which are respectively connected to two in...

Embodiment 3

[0044] The joint filler prepared in Example 2 was sprayed on the surface of the cement base material, and immediately foamed in 3 seconds, rapidly increased in size, solidified in 10 minutes, and reached working hardness in 4 hours, and then the performance test could be performed. Spray the caulking agent on the surface of wood and metal products, and test the performance of caulking after drying respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap