Metal matte granulating system and operation method thereof

An operation method and metal matte technology, applied in the direction of drum furnace, crucible furnace, furnace, etc., can solve the problems of poor quality of matte, high failure rate of equipment operation, shortened equipment life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

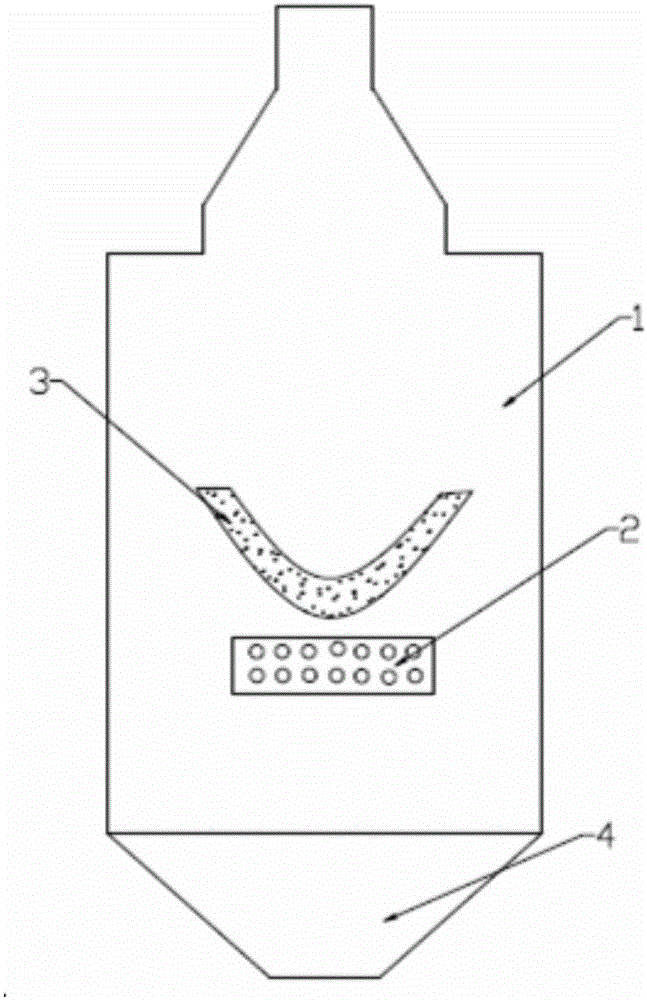

[0056] A granulator and a cooling water nozzle are arranged inside the granulation tower, and the cooling water nozzle is arranged directly below the granulator. The bottom of the granulation tower is provided with a sedimentation tank and a transportation device, and one end of the transportation device is placed on the in the sedimentation tank;

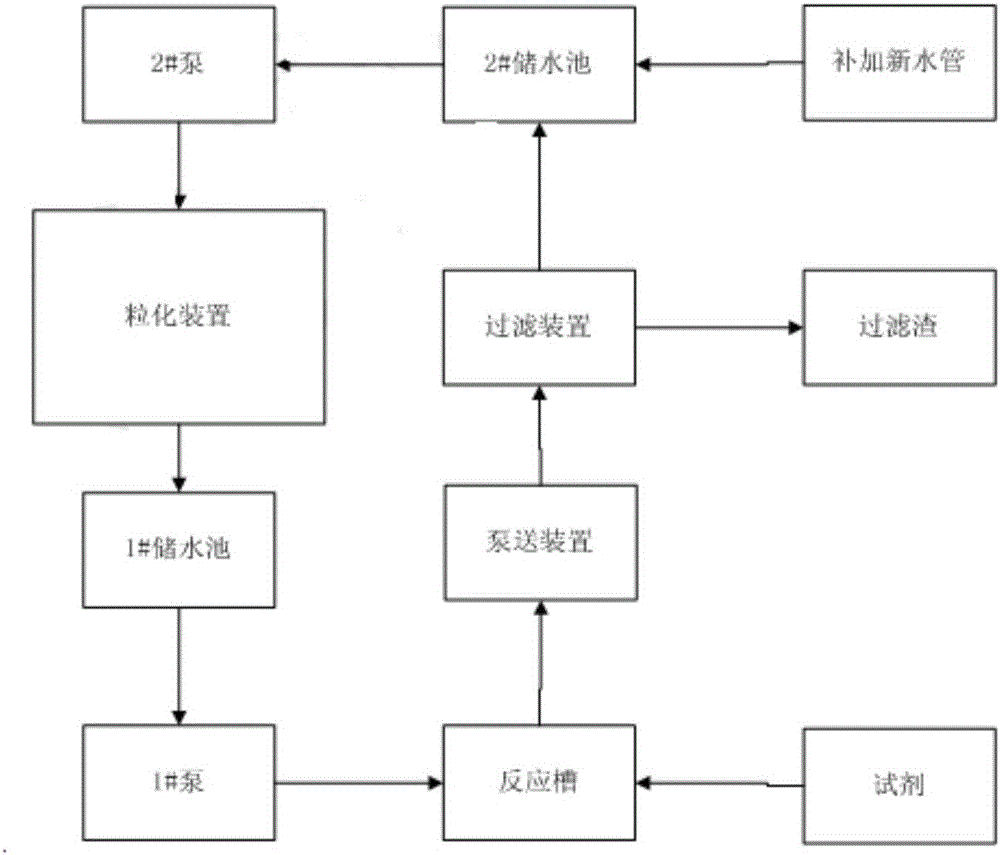

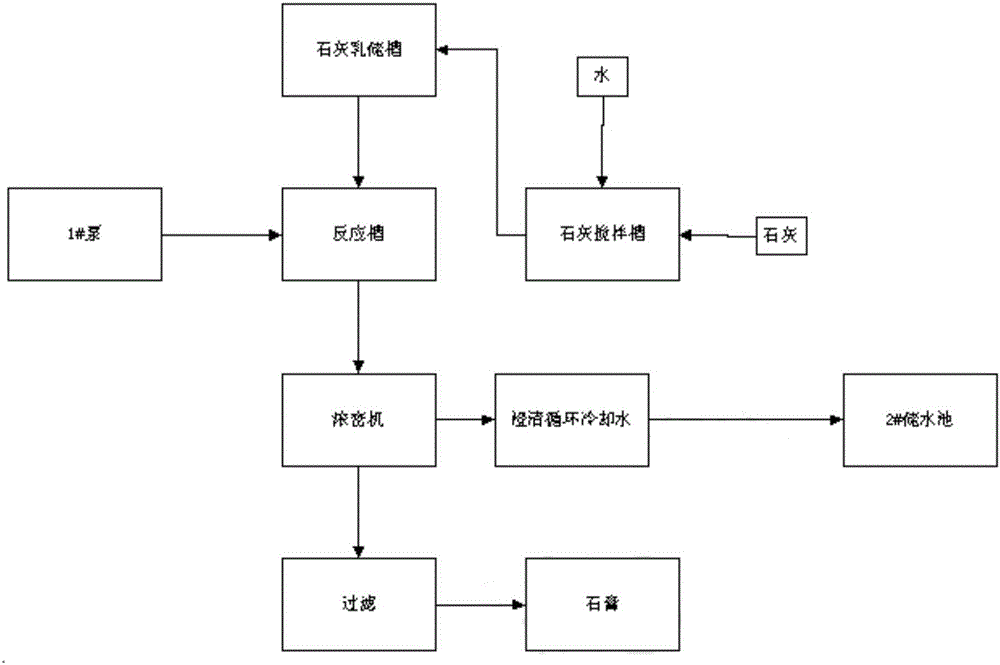

[0057] The outlet of the sedimentation tank is connected to the inlet of the 1# water storage tank, the 1# pump is arranged in the inside of the 1# water storage tank, and the outlet of the 1# pump is connected to an inlet of the reaction tank, and the milk of lime storage tank The outlet is connected to the other inlet of the reaction tank, the outlet of the lime stirring tank is connected to the inlet of the milk of lime storage tank, the outlet of the reaction tank is connected to the inlet of the pumping device, and the outlet of the pumping device is connected to the inlet of the filtering device connected, the outlet of the f...

Embodiment 2

[0059] Lime milk preparation: The prepared lime milk contains Ca(HO) 2 20kg / m 3 , that is, weigh 20kg (90%) of calcium oxide, put it into a reaction vessel, add 1000kg of water, and stir evenly.

[0060] Metal matte granulation: Metal matte is discharged from the smelting furnace and enters the granulator in the granulation tower. The metal matte is granulated by the granulator and becomes molten droplets. The molten droplets are cooled by the cooling water sprayed from the cooling water nozzle. Metal matte particles, metal matte particles and cooling water enter the sedimentation tank at the bottom of the granulation tower together, after sedimentation, the conveyor belt takes the metal matte particles out of the granulation tower and separates them from the cooling water, and the cooling water enters the first In the water storage tank, part of the cooling water in the first water storage tank overflows into the second water storage tank, and the 1# pump pumps the remaining...

Embodiment 3

[0065] The preparation process of milk of lime is the same as that of Example 2 with the granulation process of metal matte, the difference is: the process of removing sodium sulfite and sodium sulfate: the cooling water contains SO 4 2- and SO 3 2- When the concentration is 0.5mol / L, inject 10m into the reaction tank 3 Cool water, then slowly add 19m 3 Lime milk, and keep stirring for 30min.

[0066] After stirring and reacting, the reacted solution was pumped to a filter press by 1# pump for filtration.

[0067] After filtering through a filter press, the filtrate (SO 4 2- and SO 3 2- The concentration is 0.01mol / L) and filter residue (gypsum), and the filtrate enters the storage tank as cooling water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com