A kind of highly anti-oxidation minimal lubrication cutting oil and its preparation method and application

A technology of micro-lubrication and cutting oil, which is applied in the field of lubricating oil, can solve problems such as poor control system action, filter clogging, and performance degradation, and achieve good anti-oxidation effect, excellent service life, and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

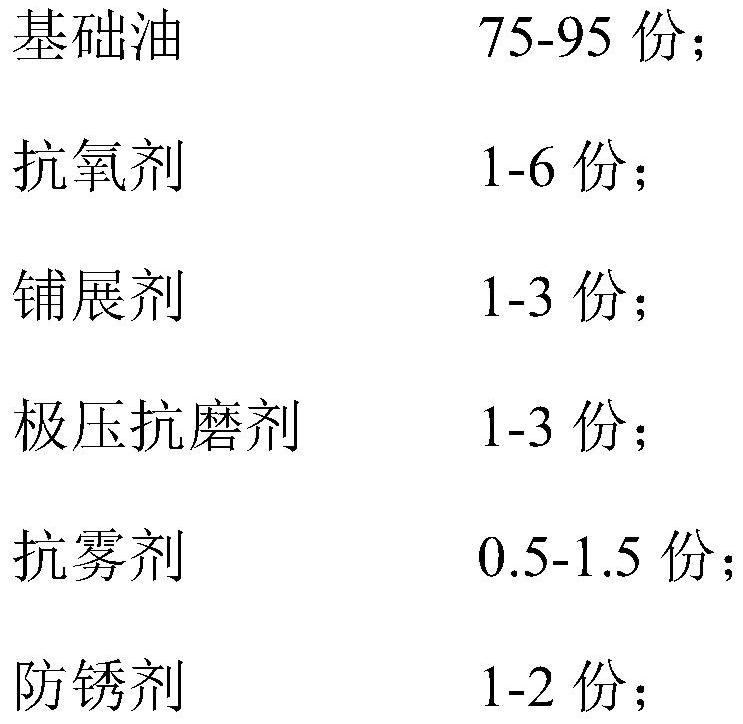

[0031] A kind of high anti-oxidation minimal lubrication cutting oil, in parts by weight, comprises the following components:

[0032]

[0033]

[0034] Wherein, the base oil is a mixture of straight-chain alkanes and rapeseed oil with a carbon number of 12, and the mixing mass ratio is 80:5;

[0035] The antioxidant is composed of shielded phenolic antioxidant, aromatic amine antioxidant and phenolamine antioxidant with a mass ratio of 1:1:1, of which the shielded phenolic antioxidant is 2,6-di tert-butyl-p-cresol, aromatic amine antioxidant is phenyl-α naphthalene, phenolic amine antioxidant is 2-hydroxy-4-n-octyloxy-benzophenone;

[0036] Spreading agent is Guerbet alcohol;

[0037] The extreme pressure antiwear agent is di-n-butyl phosphite;

[0038] The antifogging agent is ethylene propylene copolymer with a molecular weight of 15000;

[0039] The antirust agent is a mixture of calcium sulfonate and benzotriazole with a base value of 400TBN, and the mixing mass ...

Embodiment 2

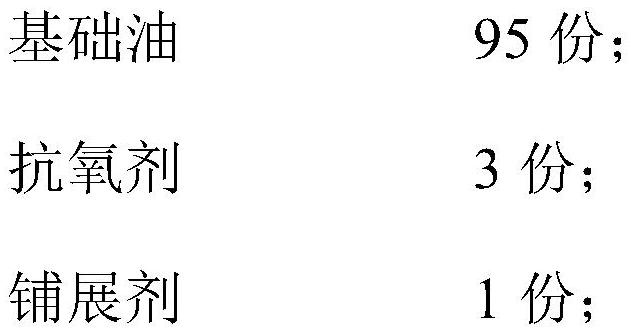

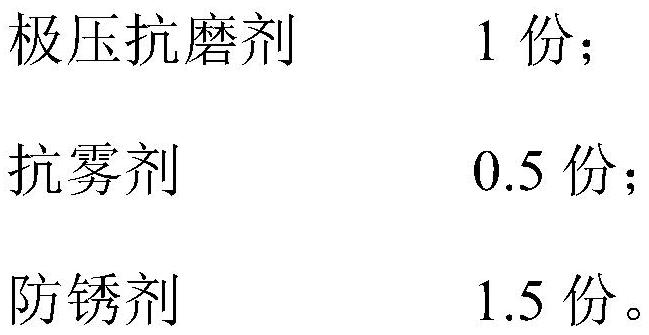

[0042] A kind of high anti-oxidation minimal lubrication cutting oil, in parts by weight, comprises the following components:

[0043]

[0044]

[0045] Wherein, the base oil is a mixture of straight-chain alkanes and rapeseed oil with a carbon number of 13, and the mixing mass ratio is 85:6;

[0046] The antioxidant is composed of shielded phenolic antioxidant, aromatic amine antioxidant and phenolamine antioxidant with a mass ratio of 1:3:3, and the shielded phenolic antioxidant is 2,6-di tert-butylamino-p-cresol, arylamine-type antioxidant is phenyl-α naphthalene, phenolamine-type antioxidant is 2-hydroxy-4-n-octyloxy-benzophenone;

[0047] Spreading agent is Guerbet alcohol;

[0048] The extreme pressure antiwear agent is di-n-butyl phosphite;

[0049] The anti-fogging agent is polyisobutylene with a molecular weight of 15000;

[0050] Rust inhibitor is methyl benzotriazole.

[0051] A preparation method of high oxidation resistance micro-lubricating cutting oil,...

Embodiment 3

[0053] A kind of highly antioxidative minimal quantity lubricating cutting oil, is basically the same as embodiment 1, and its difference is that the shielding phenol type antioxidant in the described antioxidant consists of 2,6-di-tert-butyl p-cresol and 2, 6-Di-tert-butylamino-p-cresol is compounded, and the compounding mass ratio is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com