Carbonate-based slurry fracturing with solid acid for unconventional reservoir

An unconventional, solid acid technology, applied in the field of hydraulic fracturing fluid, which can solve the problems of high consumption and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

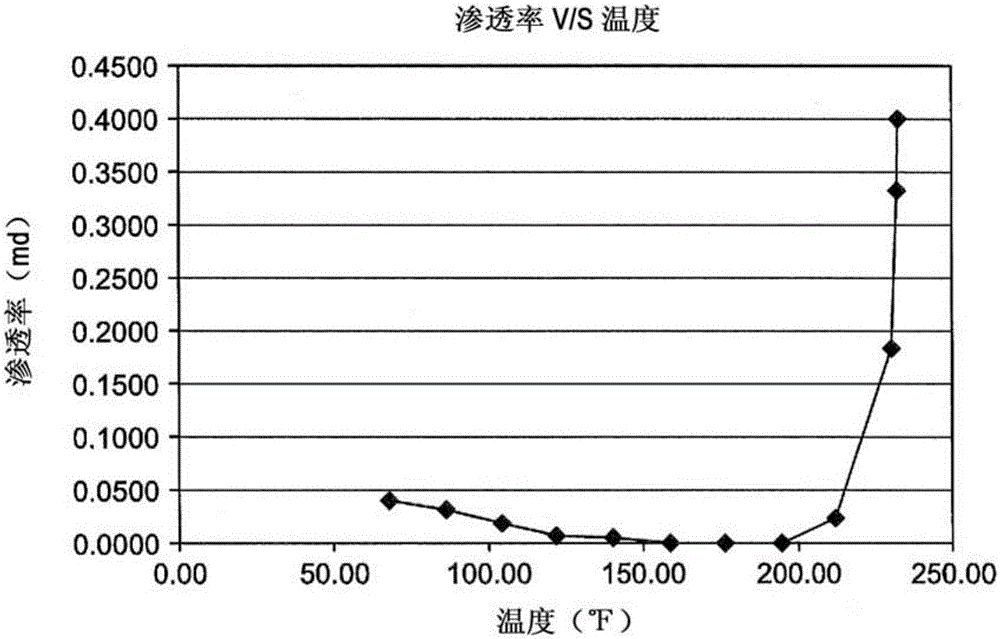

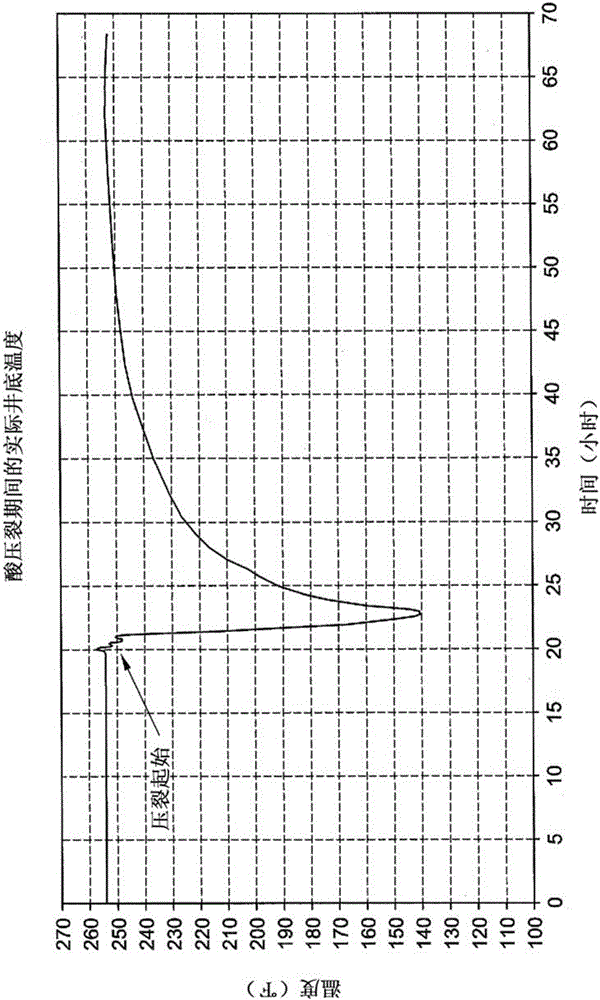

[0031] A laboratory simulation was performed using a slurry fracturing fluid according to an embodiment of the present invention. A slurry fracturing fluid was prepared using 30 g of calcium carbonate, 25 g of Portland cement, 20 g of solid acid (carboxylic acid), 15 g of sand, and 10 g of bentonite. Sufficient water is added thereto as slurry water to form a slurry-like fracturing fluid. Slurry fracturing fluid is dropped into plugs and loaded into core flooding rigs. Apply reservoir level pressure. The pressure applied on the sample was 2000 psi, the upstream pressure was 1000 psi and the downstream pressure (back pressure) was 500 psi. The permeability of the plug samples was measured while the temperature was raised from room temperature to reservoir condition 111°C (231°F). Permeability was measured according to the chemical formula shown in Table 1.

[0032] Table 1.

[0033]

[0034] Permeability results in figure 1 shown in . Such as figure 1 As shown, the p...

Embodiment 2

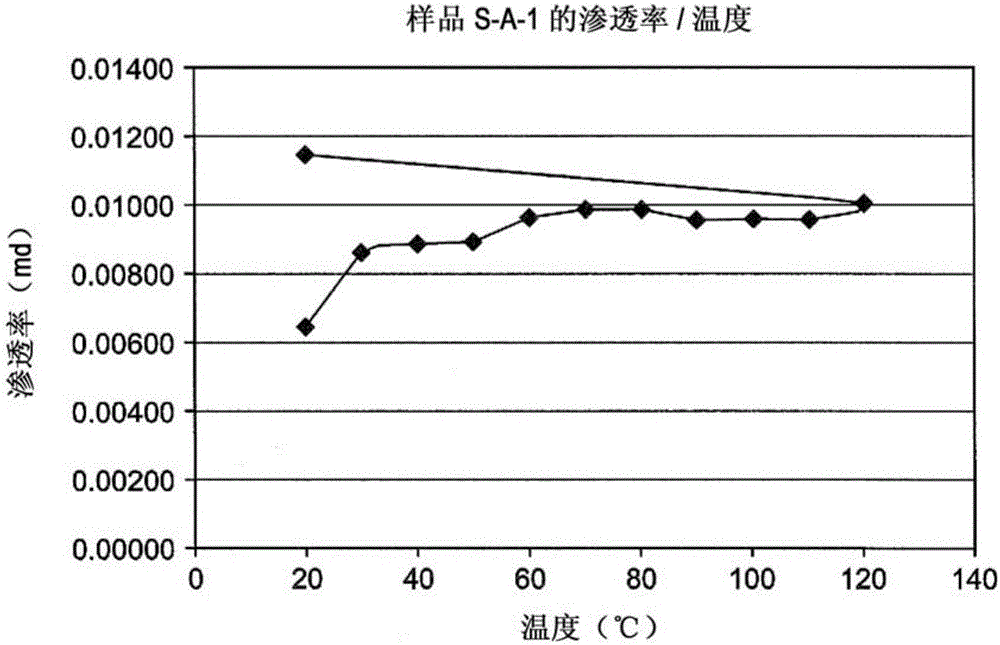

[0040] Same as in Example 1, the laboratory simulation is carried out using slurry fracturing fluid. A second slurry fracturing fluid was prepared using 40 g of calcium carbonate, 25 g of Portland cement, 20 g of solid acid (carboxylic acid), and 15 g of sand. Sufficient water is added to it to create a slurry-like fracturing fluid. Slurry fracturing fluid is dropped into the plug and loaded into the core drive unit. Apply reservoir level pressure. The pressure applied on the sample was 2000 psi, the upstream pressure was 1000 psi and the downstream pressure (back pressure) was 500 psi. The permeability of the plug samples was measured while the temperature was raised from room temperature to reservoir condition 111°C (231°F). Permeability was measured according to the chemical formula shown in Table 2. The results are shown in Table 3.

[0041] table 3

[0042] temperature

[0043] Such as Figure 4 As shown, the permeability increases when the temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com