Soak-off gel and preparation method thereof

A technology of nail polish and active diluent, which is applied in manicure, pedicure, pharmaceutical formulations, etc. It can solve the problems of inconvenient production and use of nail polish, and achieve good peeling effect, high gloss and high toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

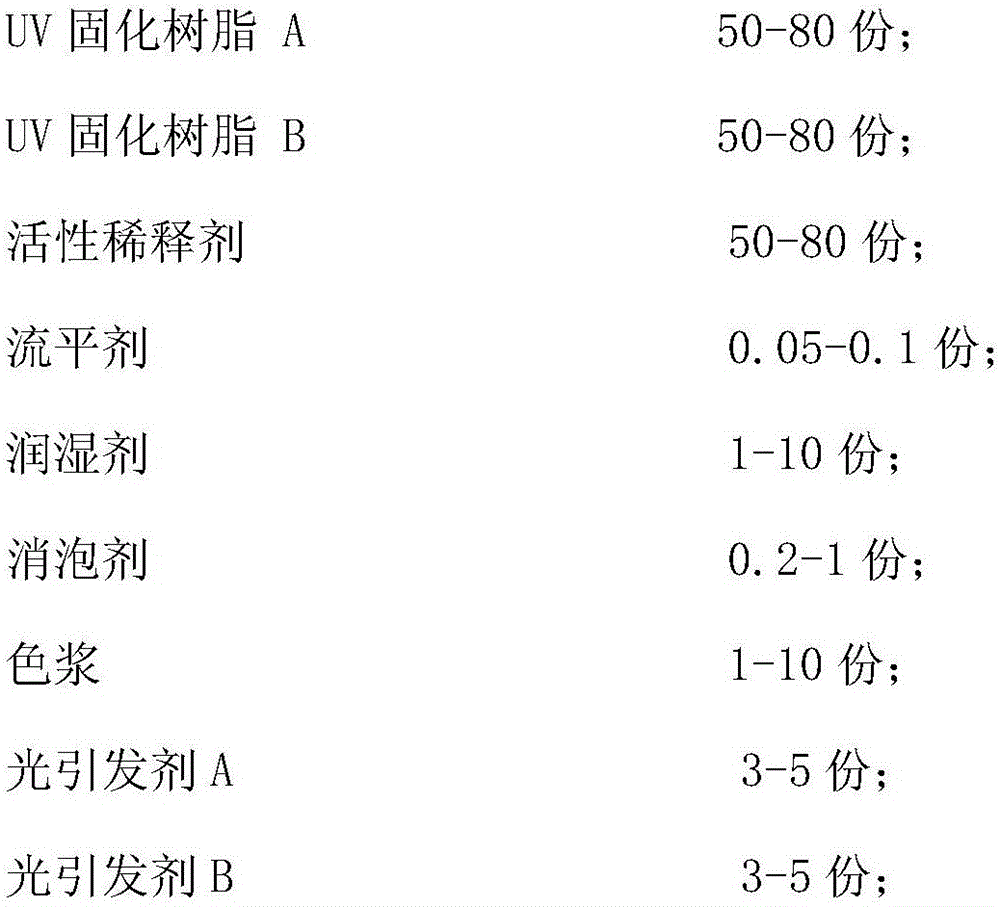

[0040] A peelable nail polish, calculated in parts by weight, its raw material composition and content are as follows:

[0041]

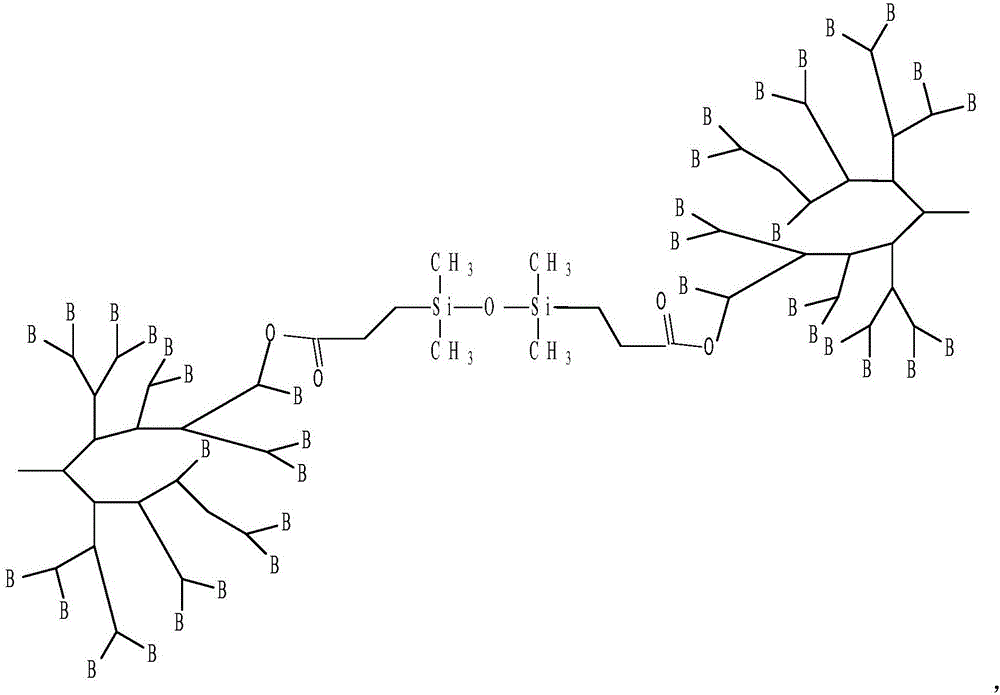

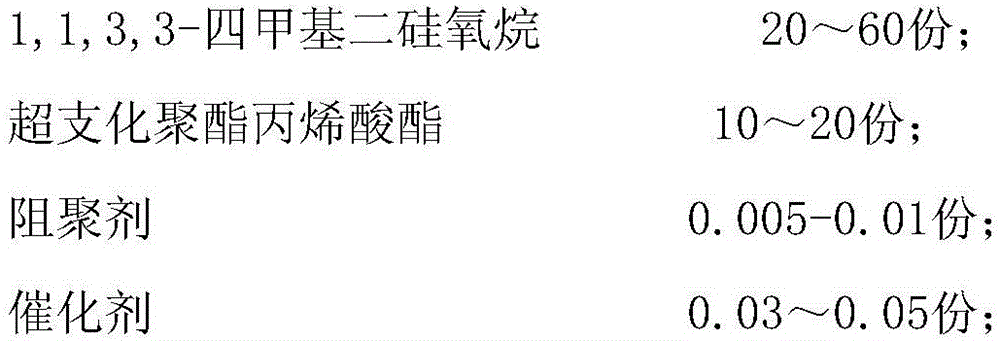

[0042] Wherein said UV curable resin A is calculated in parts by weight, and its composition and content are as follows:

[0043]

[0044] Described UV curing resin A is prepared as follows:

[0045] Add 20 parts of methylphenyl hydrogen-containing silicone oil and 10 parts of hyperbranched polyester acrylate into a 500ml three-necked flask, then add 0.005 of a polymerization inhibitor, pass in a protective gas, stir and heat, and raise the temperature to 60°C. Add 0.03 part of catalyst, keep stirring for 3 hours, stop heating, wait until the temperature of the flask drops to room temperature, and obtain UV curable resin A.

[0046] UV curing resin B is a hyperbranched polyester acrylate prepolymer;

[0047] The reactive diluent is a mixture composed of dipentaerythritol hexaacrylate, diethylene glycol diacrylate, tetrahydrofuran acrylate, a...

Embodiment 2

[0061] A peelable nail polish, calculated in parts by weight, its raw material composition and content are as follows:

[0062]

[0063]

[0064] Wherein said UV curable resin A is calculated in parts by weight, and its composition and content are as follows:

[0065]

[0066] Described UV curing resin A is prepared as follows:

[0067] Add 60 parts of methylphenyl hydrogen-containing silicone oil and 20 parts of hyperbranched polyester acrylate into a 500ml three-necked flask, then add 0.01 part of polymerization inhibitor, pass in protective gas, stir and heat, and raise the temperature to 80°C. Add 0.05 parts of catalyst, keep stirring for 5 hours, stop heating, wait until the temperature of the flask drops to room temperature, and obtain UV curable resin A.

[0068] UV curing resin B is a hyperbranched polyester acrylate prepolymer;

[0069] The reactive diluent is a mixture of dipentaerythritol hexaacrylate, diethylene glycol diacrylate, tetrahydrofuran acrylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap