Green tea extract-ferroferric oxide composite catalyst and application thereof

A technology of composite catalyst and ferroferric oxide, which is applied in the field of water treatment to achieve the effects of easy recycling, strong reducibility, and improved catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

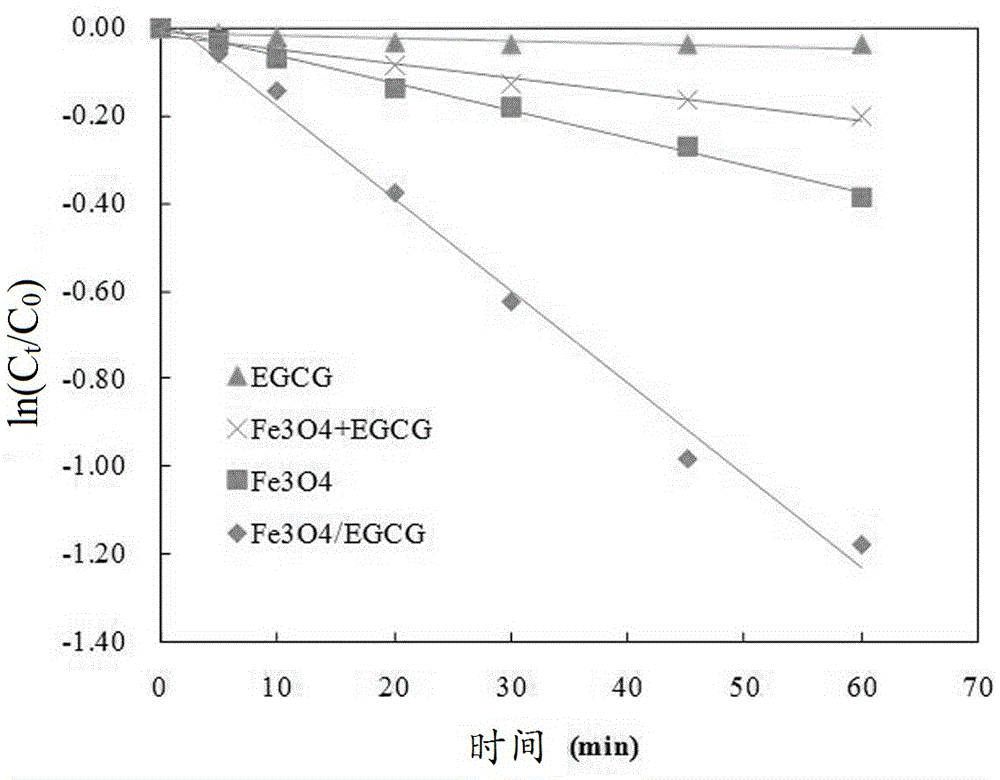

[0028] This embodiment provides a green tea extract-ferric oxide composite catalyst and a method for removing emerging organic pollutants in water by combining the composite catalyst with persulfate.

[0029] The preparation method of composite catalyst is as follows: 1) take by weighing 2.7gFeCl 3 ·6H 2 O, 7.2g NaAc, 2.0g polyethylene glycol 4000, dissolved in 80mL ethylene glycol. The mixed solution was magnetically stirred for 30 minutes to fully dissolve it, then added to a 100mL stainless steel autoclave lined with polytetrafluoroethylene, put the autoclave into an oven, raise the temperature to 200°C and keep it for 8-72 hours, then Naturally cool to room temperature.

[0030] 2) The obtained black solid was repeatedly washed several times with ethanol and ultrapure water, and placed in a vacuum oven at 60° C. for 12 hours to obtain ferric oxide powder.

[0031] 3) Weigh ferric iron tetroxide and green tea extract, put them in ultrapure water, ultrasonically disperse ...

Embodiment 2

[0037]The difference between this embodiment and Example 1 is that the dosage of the composite catalyst is 60 mg, and the removal rate of diuron reaches 89% after shaking for 60 minutes.

Embodiment 3

[0039] The difference between this embodiment and Example 1 is that the initial concentration of potassium hydrogen persulfate is 2.0 mM, and the removal rate of diuron reaches 82% after shaking for 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com