Machining method for etching quartz glass through ultrasonic-assisted laser plasma back wet etching method

A quartz glass, ultrasonic-assisted technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of severe residual stress and microcracks in the recast layer, affecting the quality of quartz glass surface processing, etc., and achieve good processing results , low cost, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

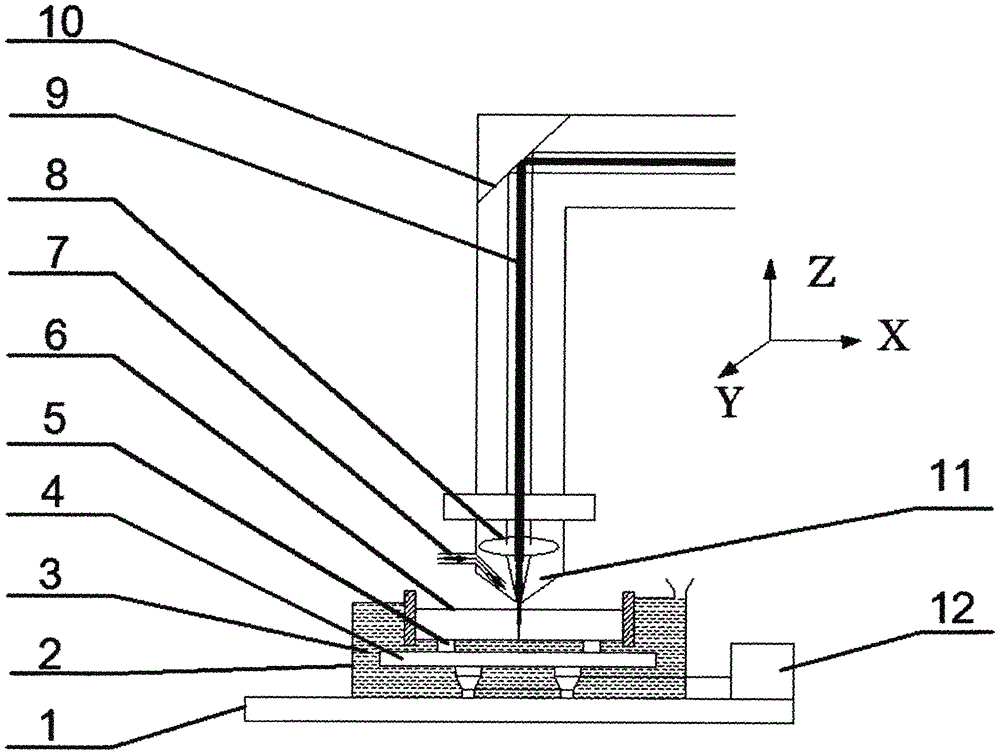

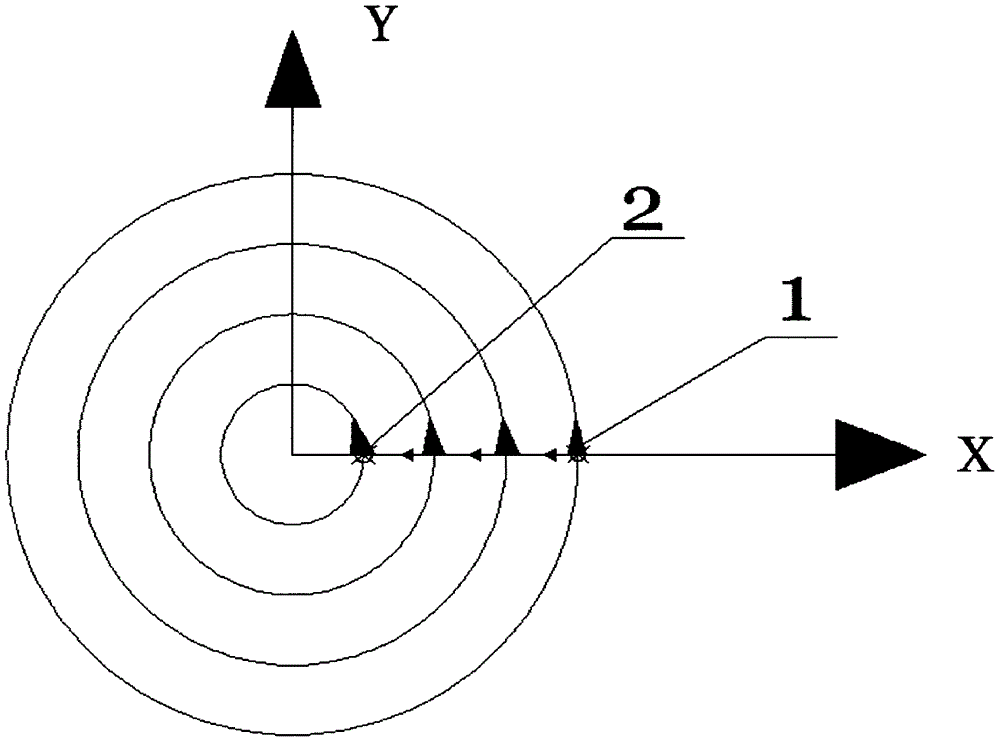

[0028] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below by selecting reasonable laser system process parameters and ultrasonic system process parameters in conjunction with the accompanying drawings.

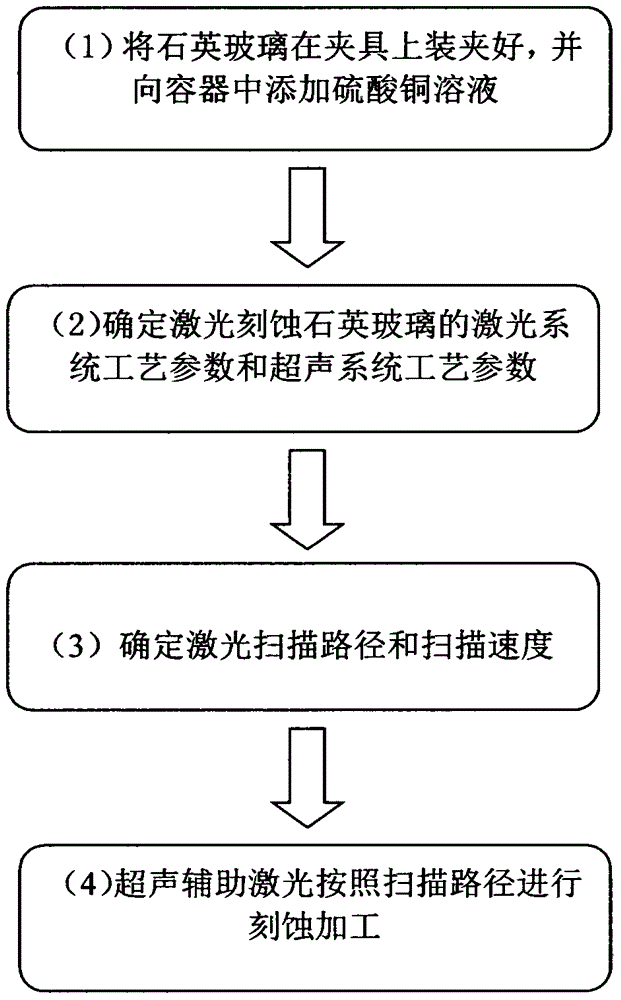

[0029] see figure 2 , a processing method for etching quartz glass by ultrasonic-assisted laser plasma back wet etching, comprising:

[0030] (1) Fix the quartz glass on the fixture, and add copper sulfate solution to the container:

[0031] The size of the quartz glass sheet is 50x50x3mm. Fix the quartz glass at a reasonable position on the workbench so that the processing position is exactly the center of the quartz glass sheet, and add copper sulfate solution to the container until the container is full of solution.

[0032] (2) Determine the laser system process parameters and ultrasonic system process parameters for laser etching quartz glass:

[0033] Start the air switch and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com