PVC (polyvinyl chloride) hose

A technology of hoses and raw materials, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of loss of sexual characteristics, disorder of sex hormones, short male reproductive organs, etc., to prolong service life and resist iron damage. The effect of strong aging and improvement of physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

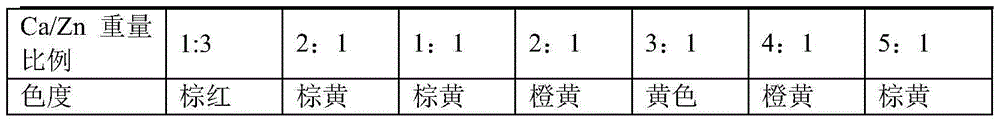

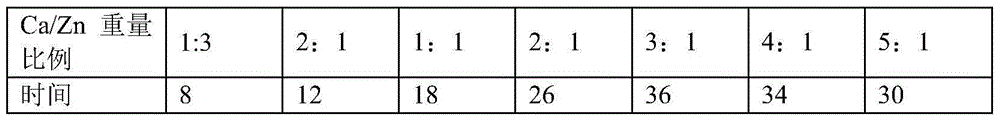

[0039] S1. 100 parts of SG-3PVC resin, 40 parts of tributyl citrate, 8 parts of epoxy soybean oil, 16 parts of dioctyl terephthalate, 0.9 parts of Ca / Zn composite stabilizer, and 0.1 part of stearic acid , 4 parts of carbonamide, 1 part of sodium alkylbenzene sulfonate and 1 part of potassium sorbate were put into a high-speed mixer, kneaded until the temperature reached 105°C and discharged, put into a low-speed cooling mixer and cooled to normal temperature to obtain a mixed powder; S2 . Put the mixed powder into the hopper of the extruder. The hopper is equipped with a forced feeding device to prevent the powder from bridging, and the hopper seat strengthens the water cooling device to prevent the powder from being heated and stuck; S3. The extruded pipe adopts a Φ90 extruder with a screw The length-to-diameter ratio is 1:28, the screw type is BM type (separate type), and the temperature control is (five-zone heating of the fuselage): 140°C in the first zone, 150°C in the se...

Embodiment 2

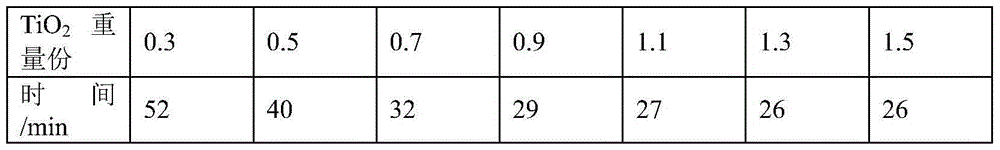

[0041]S1. 100 parts of SG-3PVC resin, 50 parts of tributyl citrate, 5 parts of epoxy soybean oil, 11 parts of dioctyl terephthalate, 1.3 parts of Ca / Zn composite stabilizer, and 0.1 part of stearic acid , 0.02 parts of whitening agent, 0.02 parts of ultramarine blue, 1.5 parts of ACR resin, 1.5 parts of titanium dioxide, 8 parts of carbonamide, 2 parts of sodium alkylbenzene sulfonate and 2.3 parts of potassium sorbate were put into the high-speed mixer and kneaded until the temperature reached 105 ℃ discharge the material, put it into a low-speed cooling mixer to cool to normal temperature, and obtain the mixed powder; S2, put the mixed powder into the hopper of the extruder, the hopper is equipped with a forced feeding device to prevent the powder from bridging, and the hopper seat strengthens The water-cooling device prevents the powder from sticking when heated; S3, the extruded pipe adopts a Φ90 extruder, the screw length-to-diameter ratio is 1:28, the screw type is BM typ...

Embodiment 3

[0043] S1, 100 parts of SG-3PVC resin, 45 parts of acetyl tributyl citrate, 7 parts of epoxy soybean oil, 14 parts of dioctyl terephthalate, 1.1 parts of Ca / Zn composite stabilizer, 0.1 parts of stearic acid 0.01 part of whitening agent, 0.01 part of ultramarine blue, 0.8 part of ACR resin, 0.8 part of titanium dioxide, 6 parts of carbonamide, 1.5 parts of sodium alkylbenzene sulfonate and 1.6 parts of potassium sorbate are put into the high-speed mixer and kneaded until the temperature reaches Discharge at 105°C, put it into a low-speed cooling mixer and cool to normal temperature to obtain mixed powder; S2, put the mixed powder into the hopper of the extruder, the hopper is equipped with a forced feeding device to prevent powder bridging, and the hopper seat is strengthened The power water cooling device prevents the powder from sticking when heated; S3, the extruded pipe adopts Φ90 extruder, the screw length-to-diameter ratio is 1:28, the screw type is BM type (separate type...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com