Preparation method of water-soluble green fluorescent silicon quantum dot

A technology of green fluorescence and silicon quantum dots, applied in chemical instruments and methods, luminescent materials, silicon compounds, etc., can solve the problems of complex reaction process, low quantum yield, poor water solubility, etc., and achieve simplified process flow, quantum The effect of high productivity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

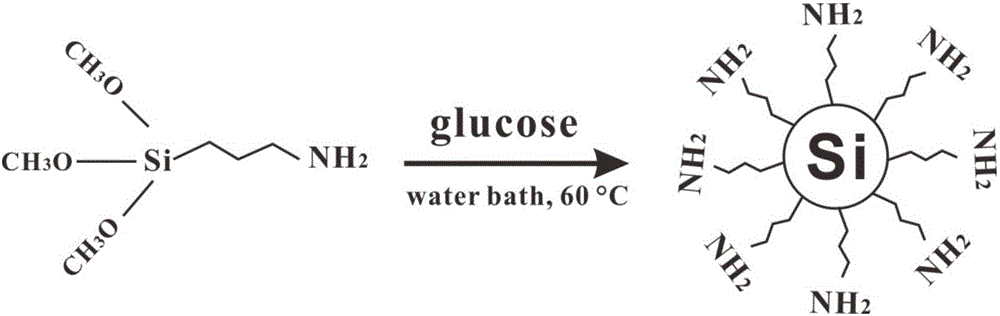

[0025] A preparation method of water-soluble green fluorescent silicon quantum dots, the steps are:

[0026] 1) Add 0.768g of glucose and 8mL of deionized water to the flask, continuously feed nitrogen into the flask, stir to dissolve the glucose completely, then inject 2.5mL of 3-aminopropyltrimethoxysilane into the flask, stir to make 3 - Aminopropyltrimethoxysilane is completely dissolved, then add 100 μL 1mol / L sodium hydroxide solution to the flask, adjust the pH to 11, continue stirring for 10 minutes, stop feeding nitrogen, then place the flask in a constant temperature water bath, and heat After the constant temperature water bath reaches 60°C, continue to stir and react for 30 minutes, and quench the solution obtained after the reaction to room temperature (25±2), to obtain crude water-soluble green fluorescent silicon quantum dots;

[0027] 2) Place a dialysis bag with a molecular weight cut-off of 1000 in a mixed solution with a concentration of NaHCO3 of 2% w / v (g / ...

Embodiment 2

[0044] A preparation method of water-soluble green fluorescent silicon quantum dots, the steps are:

[0045] 1) Add 0.768g of glucose and 8mL of deionized water into the flask, continuously feed nitrogen into the flask, stir to dissolve the glucose completely, then inject 2.5mL of 3-aminopropyltriethoxysilane into the flask, stir to make 3-Aminopropyltrimethoxysilane is completely dissolved, then add 1mol / L sodium hydroxide solution to the flask, adjust the pH to about 11, make the system in a strong alkaline environment, continue to stir for 10min, stop feeding nitrogen , and then placed the flask in a constant temperature water bath, heated the constant temperature water bath to 60°C, continued to stir for 30 minutes, and quenched the solution obtained after the reaction to room temperature (25 ± 2), to obtain the crude product of water-soluble green fluorescent silicon quantum dots;

[0046] 2) Place a dialysis bag with a molecular weight cut-off of 1000 in a mixed solution...

Embodiment 3

[0049] A preparation method of water-soluble green fluorescent silicon quantum dots, the steps are:

[0050] 1) Add 0.682g of sodium ascorbate and 8mL of deionized water into the flask, feed nitrogen into the flask, stir until the sodium ascorbate is completely dissolved, then inject 2.5mL of 3-aminopropyltrimethoxysilane into the flask, and stir until 3- Aminopropyltrimethoxysilane is completely dissolved, nitrogen gas is continuously introduced, and then 1mol / L sodium hydroxide solution is added to the flask to adjust the pH to about 11, so that the system is in a strong alkaline environment, and continue to stir for 10 minutes , stop feeding nitrogen, then put the flask into a constant temperature water bath, heat the constant temperature water bath to 60°C, continue to stir for 30 minutes, and quench the solution obtained after the reaction to room temperature (25 ± 2), to obtain water-soluble green fluorescence Crude silicon quantum dots;

[0051] 2) Place a dialysis bag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com