Method for preparing InBO3:Eu<3+> luminescent material by adopting boric acid melting process

A technology of boric acid melting method and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of mild reaction conditions, easy availability of raw materials, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 0.097g (0.35mmol) indium oxide, 0.33g (5.25mmol) boric acid, 0.0037g (0.0105mmol) Eu 2 o 3 , 0.63mL (35mmol) H 2 O mixed evenly, the resulting mixture was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and reacted at 220°C for 72 hours. Dry in oven for 24 hours to obtain spherical InBO 3 :Eu 3+ Luminescent material.

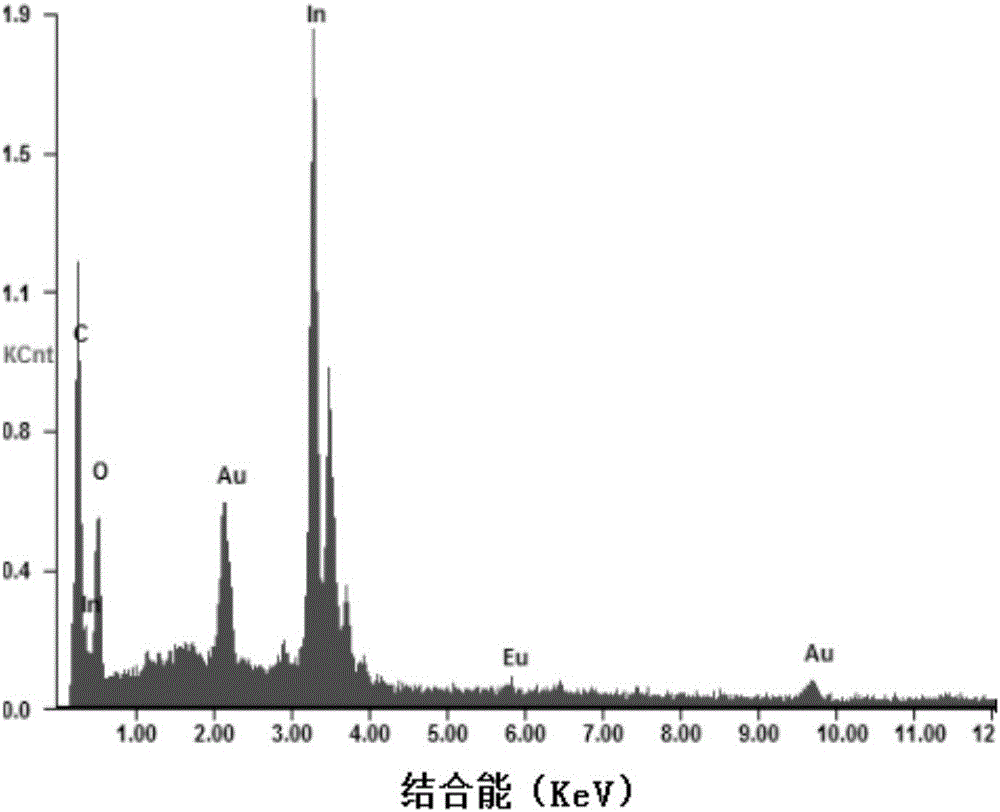

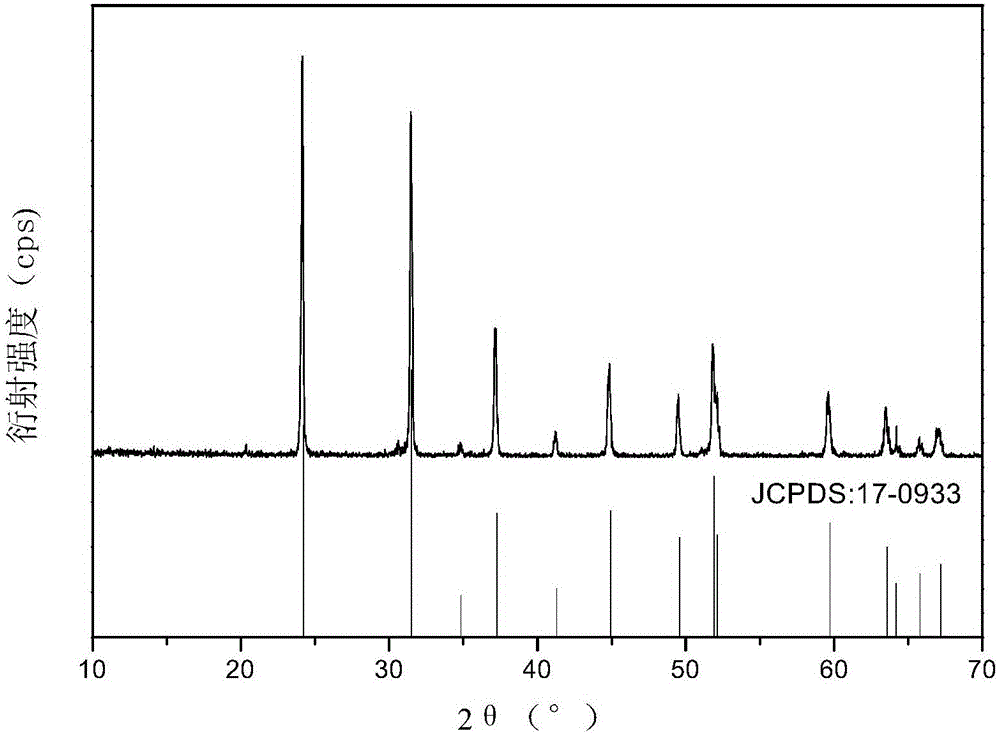

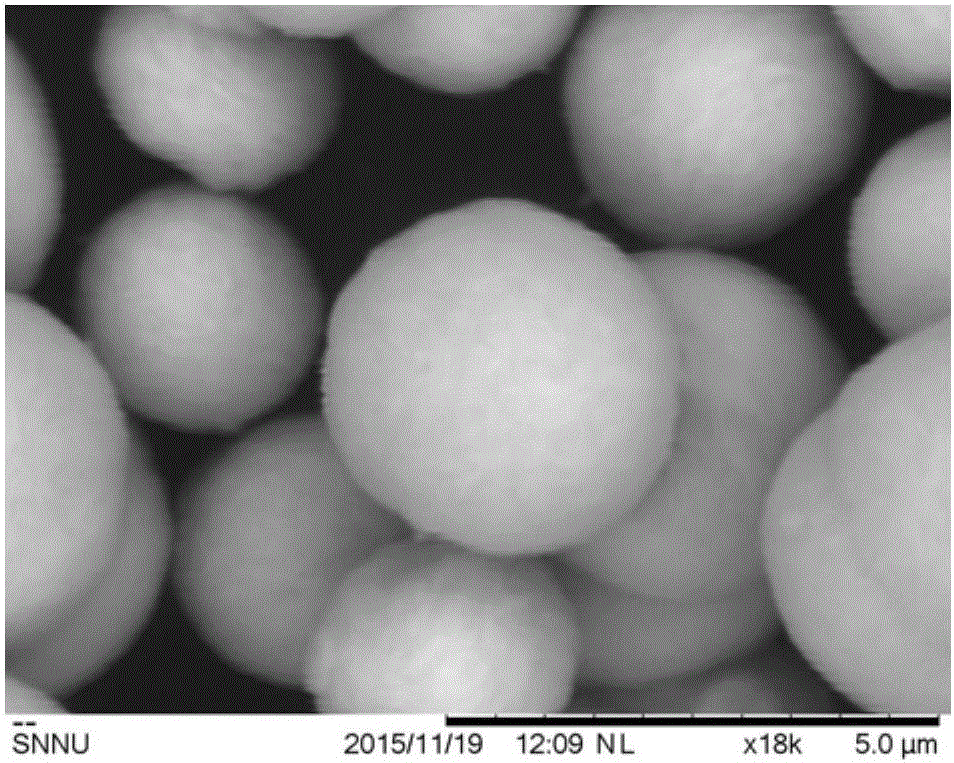

[0027] RigakuD / MAX-IIIC X-ray powder diffractometer (working conditions: Cu target Ka line, graphite filter, tube voltage 40kV, current 30mA, step size 0.02° / s, scan range: 10°~70°), Quanta200 type X-ray energy dispersive spectrometer, Quanta200 type scanning electron microscope, F-7000 type fluorescence spectrophotometer (excitation slit width and emission slit width are all 0.5 and 0.5nm. Voltage is 500V, excitation wavelength is λex= 237nm) to characterize the obtained luminescent material, the results are shown in Figure 1~4 . Depend on figure 1 It can be seen that the obtained luminescent material contains In, ...

Embodiment 2

[0029] 0.097g (0.34mmol) indium oxide, 0.35g (5.13mmol) boron oxide, 0.0060g (0.017mmol) Eu 2 o 3 , 0.70mL (39mmol) H 2 O mixed evenly, the resulting mixture was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and reacted at 240°C for 72 hours. Dry in oven for 24 hours to obtain spherical InBO 3 :Eu 3+ Luminescent material (see Figure 5 ), whose luminous intensities at wavelengths of 591nm and 613nm are 2536au and 358au, respectively.

Embodiment 3

[0031] 0.21g (0.70mmol) indium nitrate, 0.65g (10.5mmol) boric acid, 0.0074g (0.021mmol) Eu 2 o 3 , 1mL (56mmol) H 2 O mixed evenly, the resulting mixture was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and reacted at 200°C for 60 hours. Dry in oven for 24 hours to obtain spherical InBO 3 :Eu 3+ Luminescent material (see Figure 6 ), whose luminous intensities at wavelengths of 591 and 613nm are 1017au and 1326au, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light intensity | aaaaa | aaaaa |

| Light intensity | aaaaa | aaaaa |

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com