Engines with Oil Filter Coolers

A technology for engine oil cooling and engine application in the direction of machine/engine, engine components, engine lubrication, etc., which can solve the problems of complex structure of water-cooled oil cooler, difficulty in ensuring the temperature of engine oil, increasing load of the oil pump, etc., to achieve improved compactness , Increased power, improved viscosity-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

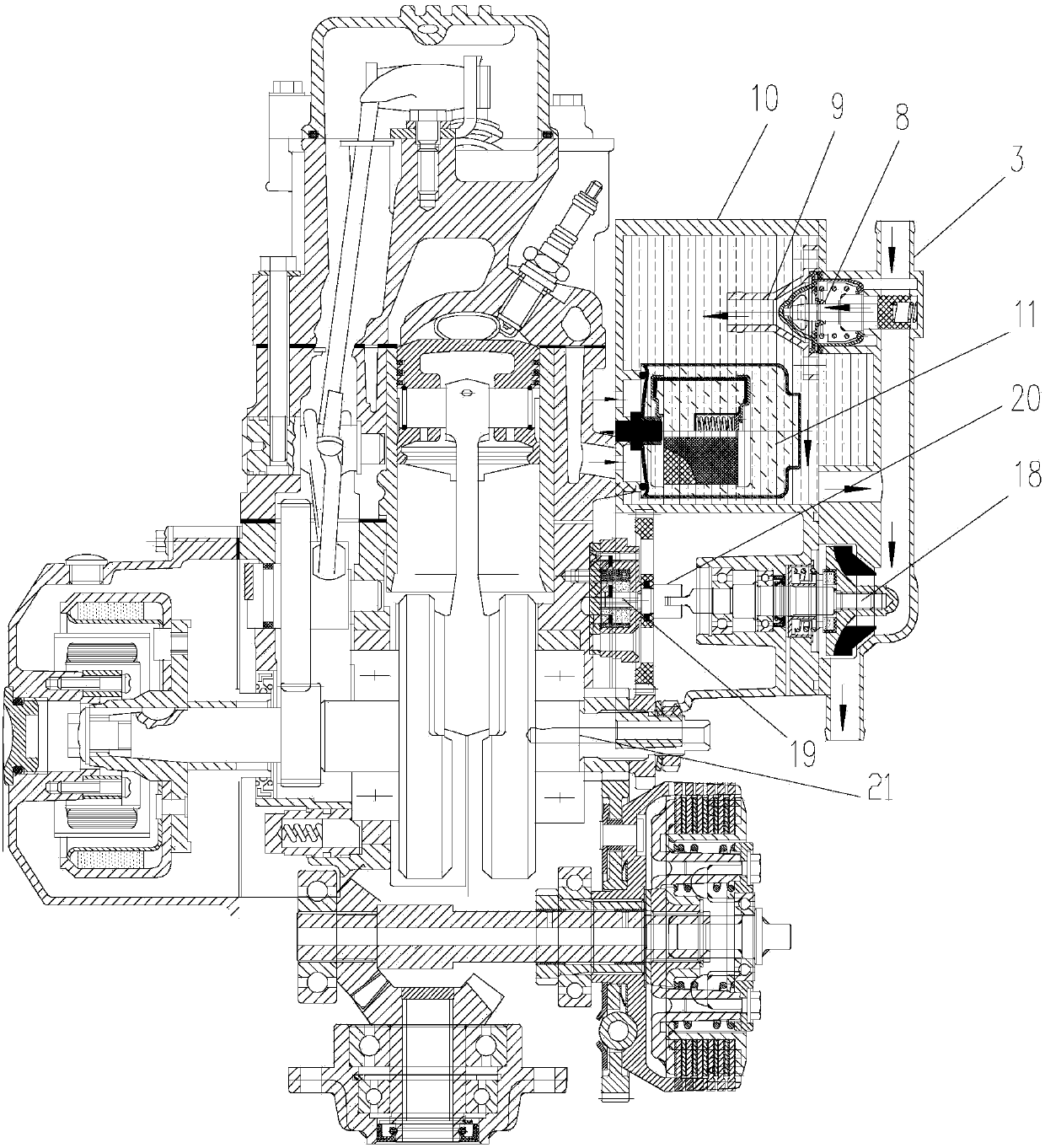

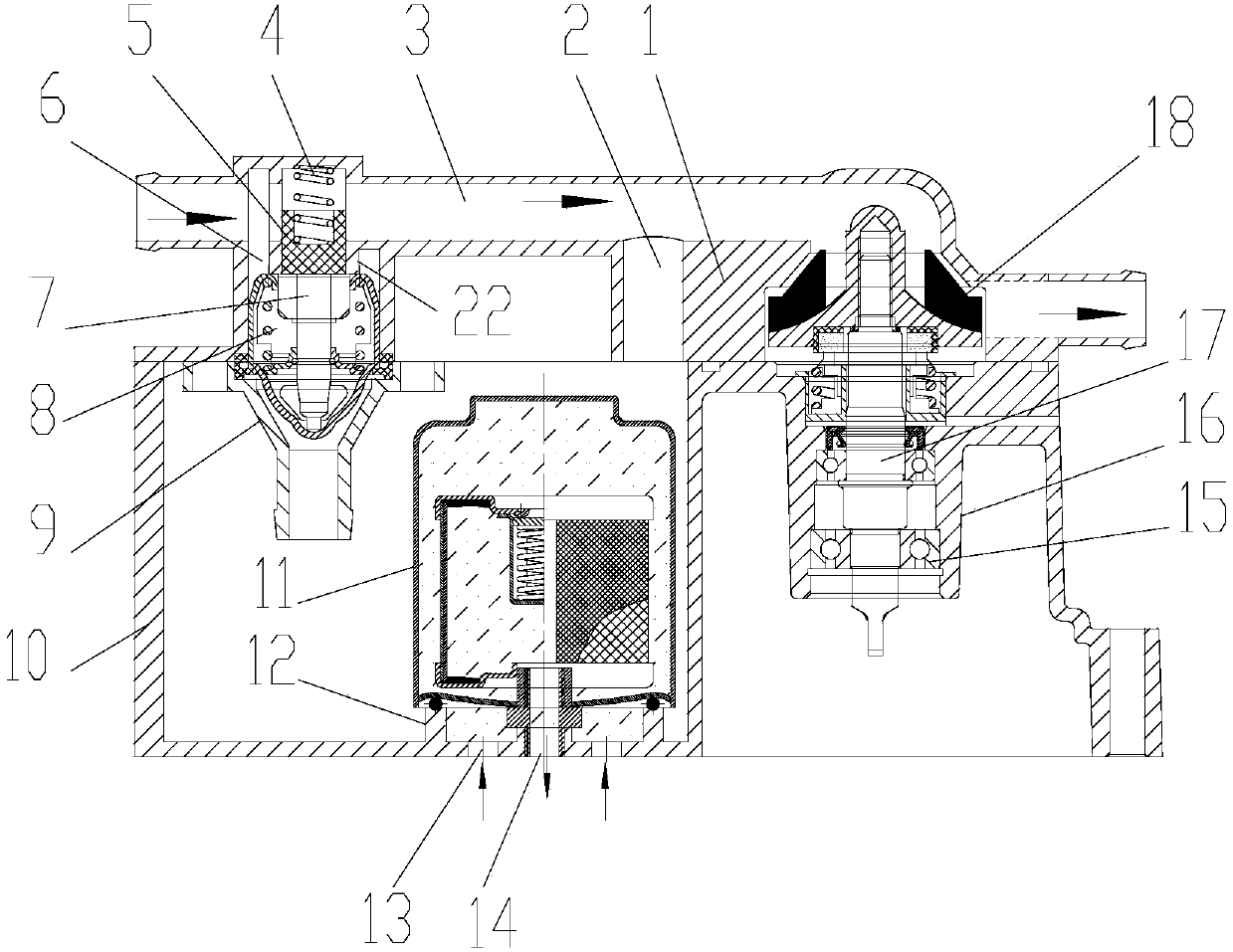

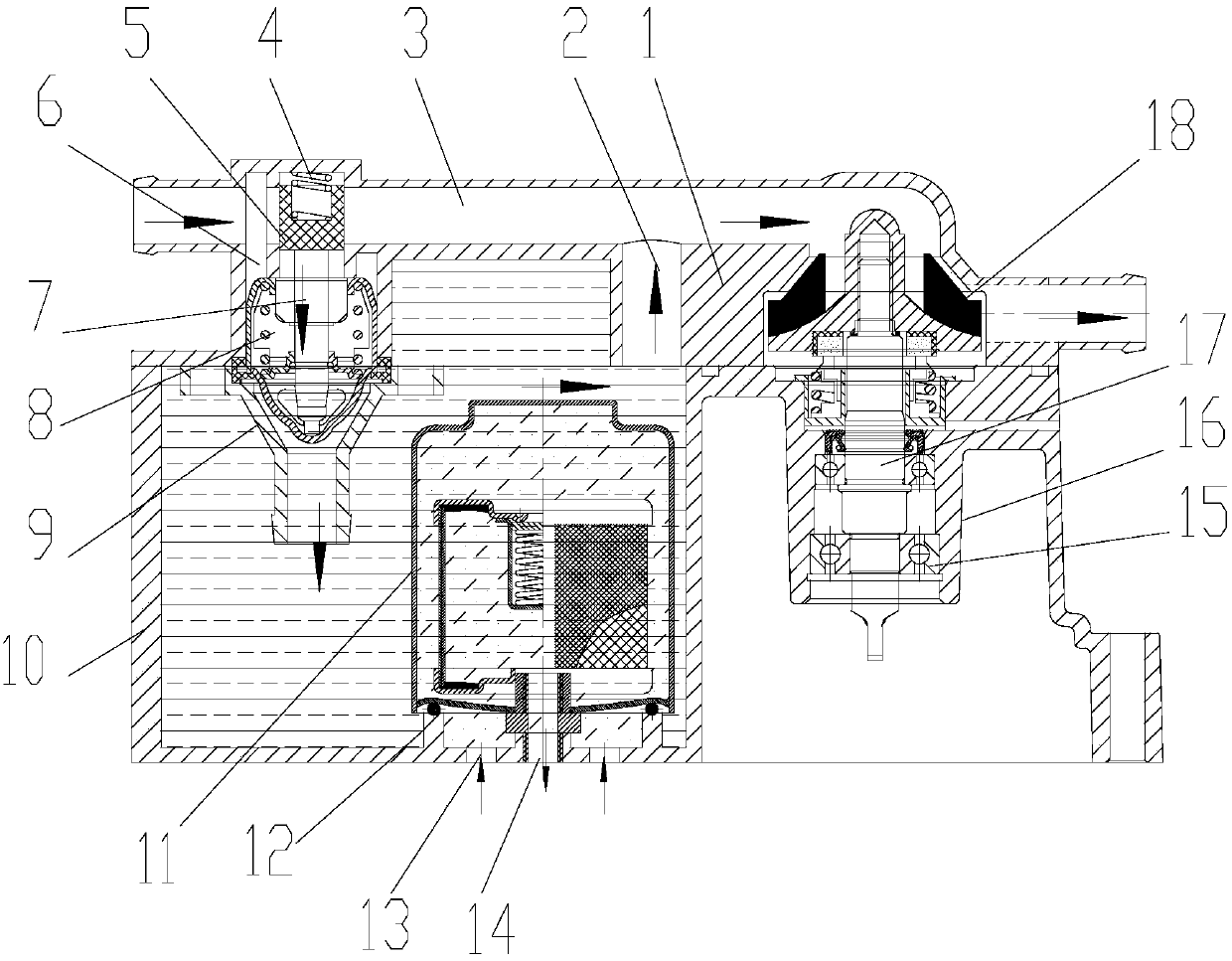

[0019] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of the flow of cooling water in the closed state of the thermostat valve 8 of the present invention; image 3 It is a schematic diagram of the cooling water flow when the thermostat valve 8 of the present invention is opened, as shown in the figure: the engine with the oil filter cooler of the present embodiment includes the engine body and the cooling water passage 3 communicated with the water jacket of the engine body , an oil cooling water tank communicated with the cooling water channel 3 through a bypass, an oil filter 11 that is connected to the lubricating oil circuit of the engine body and arranged in the oil cooling water tank, and is used to control the entry of cooling water from the cooling water channel 3 The control valve of the oil cooling water tank; the engine with the oil filter cooler of the present embodiment, the oil filter is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com