Intestine moistening and bowel relaxing yogurt drink and preparation method thereof

A technology for laxative and yogurt, applied in the direction of milk preparations, other dairy products, bacteria used in food preparation, etc. content, improve the effect of laxative health care, better taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

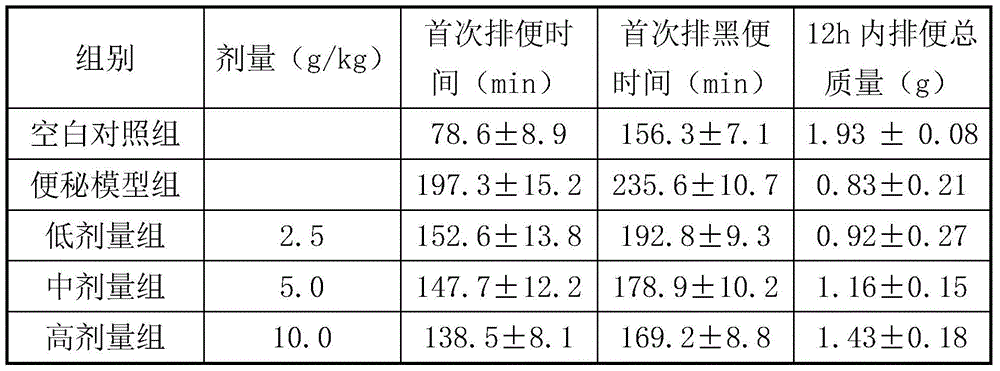

Method used

Image

Examples

Embodiment 1

[0021] The ratio of raw materials is: in every 500ml, by weight, it includes: 3g of pitaya peel soluble fiber powder, 2g of superfine powder of banana peel, 2g of superfine powder of mango peel, 2g of superfine powder of dietary fiber from carrot pomace, 1g of superfine powder of dietary fiber from apple pomace, Celery dregs dietary fiber superfine powder 1g, cucumber dregs dietary fiber superfine powder 1g, fructooligosaccharide 0.5g, green sugarcane juice 1g, kiwi fruit juice 2g, low-fat milk powder 10g, white sugar 2g, honey 1g, xanthan gum 0.2g, the rest for water.

[0022] The preparation process is:

[0023] A. Pitaya peel is dried and crushed, passed through a 100-mesh sieve, adding water 80 times the dry powder weight, adding 0.1% dry powder weight pectinase + cellulase mixed enzyme (mixing ratio is 1:2) for hydrolysis, and heating to 90 Inactivate the enzyme at ℃, filter and concentrate in a vacuum three-effect concentrator, precipitate with 95% ethanol alcohol, sepa...

Embodiment 2

[0028] In every 500ml, by weight, it includes: pitaya peel soluble fiber powder 5g, banana peel superfine powder 3g, mango peel superfine powder 5g, carrot pomace dietary fiber superfine powder 5g, apple pomace dietary fiber superfine powder 1g, celery pomace dietary fiber superfine powder Micropowder 1g, cucumber dregs dietary fiber superfine powder 1g, fructooligosaccharide 0.5g, green sugarcane juice 2g, kiwi fruit juice 2g, low-fat milk powder 10g, white sugar 2g, honey 3g, xanthan gum 0.2g, and the rest is water.

[0029] The preparation process is:

[0030] A. Pitaya peel is dried and pulverized, passed through 80 mesh sieve, adding water 50 times of dry powder weight, adding 0.05% of dry powder weight pectinase + cellulase mixed enzyme (mixing ratio is 1:2) after hydrolysis, heated to 90 Inactivate the enzyme at ℃, filter and concentrate in a vacuum three-effect concentrator, precipitate with 95% ethanol alcohol, separate and filter, take the precipitate and dry it to o...

Embodiment 3

[0035] Raw material ratio is: pitaya peel soluble fiber powder 8g, banana peel ultrafine powder 7g, mango peel ultrafine powder 5g, carrot residue dietary fiber ultrafine powder 5g, apple pomace dietary fiber ultrafine powder 3g, celery residue dietary fiber ultrafine powder 3g, cucumber residue Dietary fiber superfine powder 2g, fructooligosaccharide 3g, green sugarcane juice 5g, kiwi fruit juice 5g, low-fat milk powder 25g, white sugar 3g, honey 5g, xanthan gum 0.05g, and the rest is water.

[0036] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com