A kind of hydrocracking catalyst carrier and its preparation method

A catalyst carrier, hydrocracking technology, applied in the direction of catalyst carrier, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of reducing catalyst selectivity, affecting the diffusion of reactants, etc., to achieve good hydrothermal stability and process flow. Simple, high silicon-to-aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

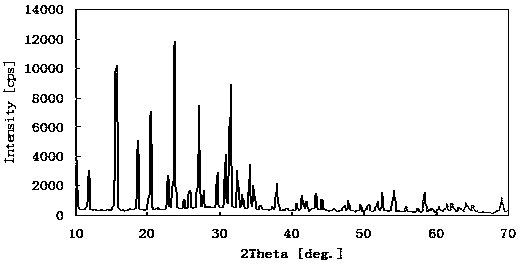

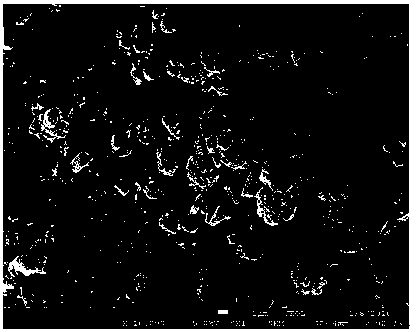

Image

Examples

preparation example Construction

[0043] In the preparation process of the modified Y-type molecular sieve used in the present invention, in the preparation method of the large-grain NaY-type molecular sieve in step (1), Na in the high-alkali sodium metaaluminate solution 2 O content is 260~320g / L, Al 2 o 3 The content is 30~50g / L, and it can be prepared by conventional methods. Na in low alkali sodium metaaluminate solution 2 O content is 100~130g / L, Al 2 o 3 The content is 60~90g / L, and it can be prepared by conventional methods. Al in aluminum sulfate solution 2 o 3 The content is 80~100g / L. SiO in water glass 2 The content is 200~300g / L, and the modulus is 2.8~3.5.

[0044] In the preparation process of the modified Y-type molecular sieve used in the present invention, the preparation method of the large-grain NaY-type molecular sieve in step (1) specifically includes the following steps:

[0045] I. According to Na 2 O: Al 2 o 3 : SiO 2 :H 2 O=10~15:1:10~20:500~600 molar ratio, at 20°C~40°C...

Embodiment 1

[0060] In this example, large-grain NaY molecular sieves were prepared by the method of the present invention.

[0061] Preparation of Y-1

[0062] (1) Preparation of gel: Slowly add 165mL of water glass to 63mL of high alkali sodium metaaluminate solution under stirring condition at a temperature of 25°C. After mixing evenly, add 42.5mL of aluminum sulfate solution and 35.6mL of low Alkaline sodium metaaluminate solution, stirred at constant temperature for 0.5 hours, and then aging the obtained synthetic solution at the above temperature for 1 hour to obtain a gel;

[0063] (2) Crystallization: Under stirring conditions, raise the gel in the synthesis kettle to 100°C at a heating rate of 2.5°C / min, stir and crystallize at a constant temperature for 16 hours, after the crystallization is completed, quickly cool down with cold water, and open the The synthesized molecular sieve was taken out from the synthesis kettle, and the product LY-1 was obtained after filtering, washing...

Embodiment 2

[0078] Firstly, ammonium exchange is carried out on the raw material large-grain NaY molecular sieve LY-1. Prepare 10 liters of 0.5 mol / L ammonium nitrate aqueous solution. Weigh 2,000 grams of small-grain NaY molecular sieves, dissolve them in 10 liters of prepared ammonium nitrate aqueous solution, stir at 90°C for 1 hour at a constant temperature of 300 rpm, then filter the molecular sieves, and leave a small sample to analyze Na 2 O content; repeat the above operation until Na in the molecular sieve 2 The O content reaches 2.5-5.0wt%, and the sample number obtained after drying is LYN-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com