Double-sphere type suspension filler

A suspended filler, spherical technology, applied in the field of water treatment, can solve the problems of inconvenient installation, maintenance and replacement, high requirements on the uniformity of water distribution and air distribution, poor microbial adhesion performance, etc., and achieves good water conservancy conditions and good metabolism. , the effect of good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

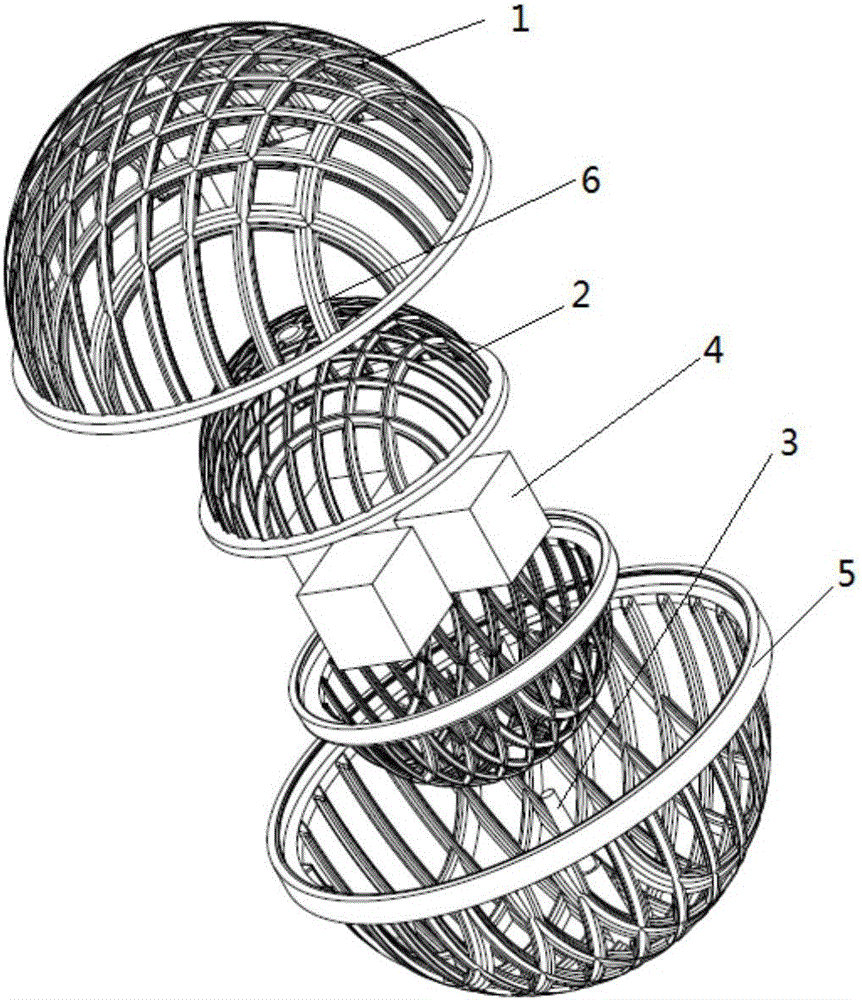

[0029] The present embodiment provides a double-spherical suspension filler, comprising a first spheroid 1 and a second spheroid 2, the diameter of the first spheroid 1 is 8-12 cm, which is 10 cm in this embodiment, and the diameter of the second spheroid 2 is 4-6cm, 6cm in this embodiment, the first sphere 1 is sleeved outside the second sphere 2, the first sphere 1 and the second sphere 2 are concentric, the first sphere 1 is connected with the second sphere 2 through a connecting rod 3; the second sphere 2 is filled with a filling sponge 4; the first sphere 1 and the second sphere 2 are respectively composed of criss-cross partition bars 6, Mesh holes are formed between the partition bars 6, and the number of the mesh holes on the first sphere 1 and the second sphere 2 is not less than 160, and the surface of the partition bar 6 is provided with grooves for The specific gravity of the filler is reduced, the strength of the separator 6 is improved, and the specific surface a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com