Modified manganese slag compound fertilizer production system

A production system and compound fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of polluting the environment, no grass in abandoned dumps, etc., and achieve the effect of making full use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

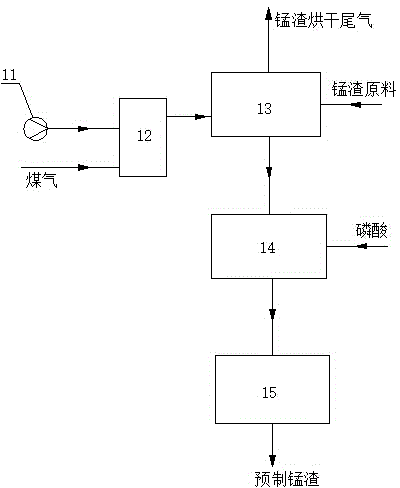

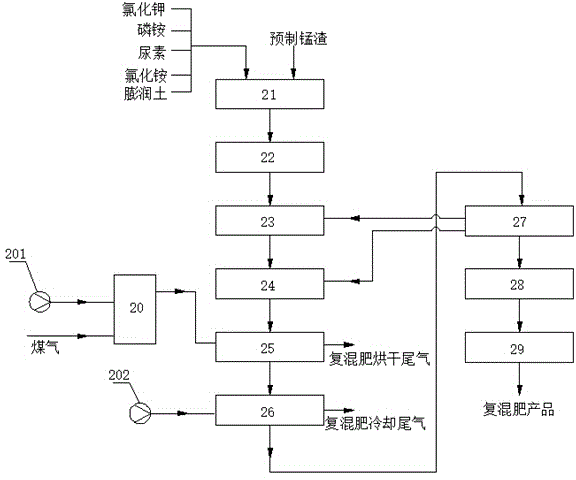

[0027] The modified manganese slag compound fertilizer production system of the present invention includes a manganese slag prefabrication system and a compound fertilizer production system.

[0028] figure 1 It is a structural schematic diagram of the manganese slag prefabrication system. As shown in the figure, the manganese slag prefabrication system includes a combustion furnace induced draft fan I11, a combustion furnace I12, a manganese slag dryer 13, an acidification modifier 14 and a neutralization reactor 15. The combustion The furnace I12 is connected to the gas pipeline, the air outlet pipe of the induced draft fan I11 of the combustion furnace is connected to the combustion furnace I12, the hot air outlet pipe of the combustion furnace I12 is connected to the manganese slag dryer 13, and the manganese slag dryer The dry mangane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com