Method for preparing agarose cross-linked gel microspheres

A cross-linked gel and agarose technology, applied in the field of polymers, can solve the problems of unfavorable column operation, high back pressure of chromatography column, and limited application, and achieve the effect of good mechanical strength, simple equipment, and uniform ball size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

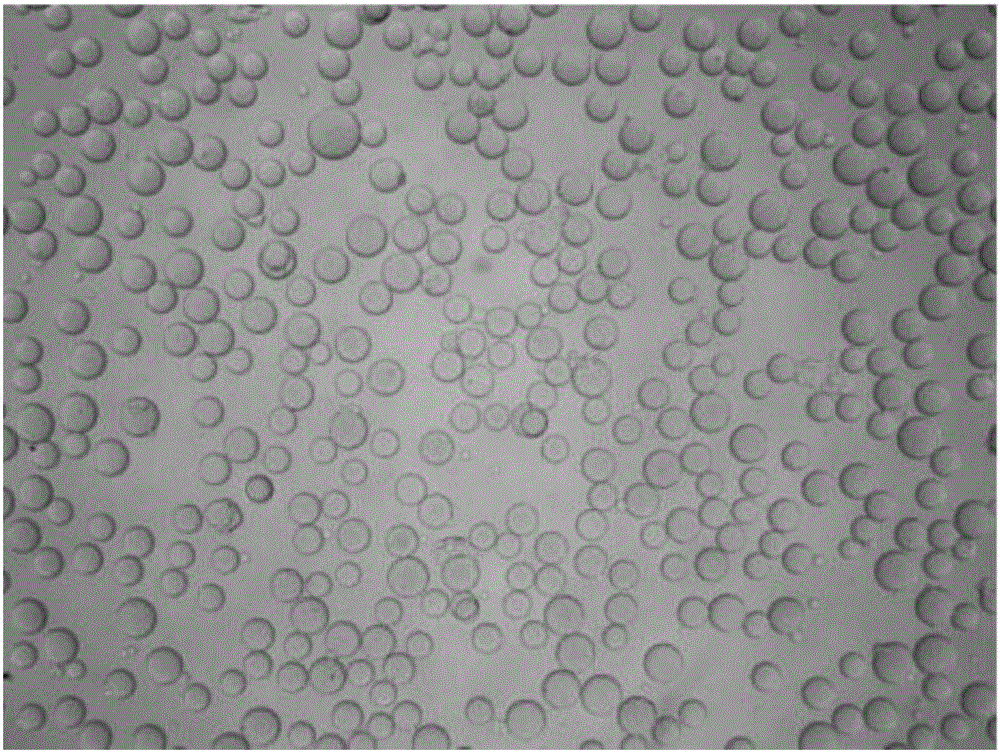

[0040] Take 7.5 g of agarose in 250 mL of water (concentration of agarose aqueous solution is 3%), stir at room temperature for 1 h, add 0.12 g of KCl and continue stirring for 0.5 h, then heat until the agarose boils and the solution becomes transparent. Prepare 1.5L toluene solution, add 23.49g polyvinyl acetate and 2.349g oleic acid. Stir the organic phase at a constant temperature at 70° C. until uniformly mixed, pour the boiling agarose aqueous solution into the organic phase, and stir for 1 hour to disperse and emulsify the agarose. Add 22.5g of epichlorohydrin at one time, add 20mL of 50% NaOH solution dropwise, and complete the dropwise addition within 1 hour. Stir and solidify for 3 hours before condensing, and control the cooling rate at 2°C / min until the temperature is cooled below 10°C. Agarose gel microspheres with a particle size of 100-300 meshes are prepared after repeated washing.

Embodiment 2

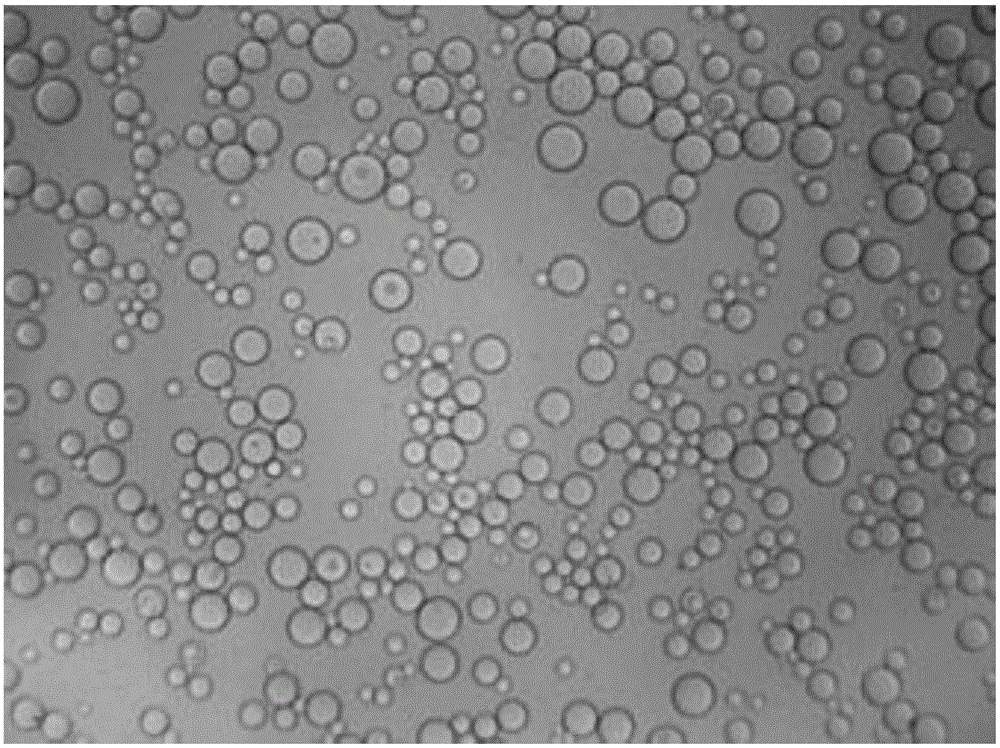

[0042] Take 10 g of agarose in 250 mL of water (the concentration of the agarose aqueous solution is 4%), stir at room temperature for 1 h, add 0.2 g of KCl and continue stirring for 0.5 h, then heat until the agarose boils and the solution becomes transparent. Prepare 1.75L toluene solution, add 30.45g polyvinyl acetate and 3.045g oleic acid. Stir the organic phase at a constant temperature at 70° C. until uniformly mixed, pour the boiling agarose aqueous solution into the organic phase, and stir for 1 hour to disperse and emulsify the agarose. Add 30g of epichlorohydrin at one time, and add 25mL of 50% NaOH solution dropwise, and the dropwise addition is completed within 1 hour. Stir and solidify for 3 hours before condensing, and control the cooling rate at 2°C / min until the temperature is cooled below 10°C. Agarose gel microspheres with a particle size of 100-300 meshes are prepared after repeated washing.

Embodiment 3

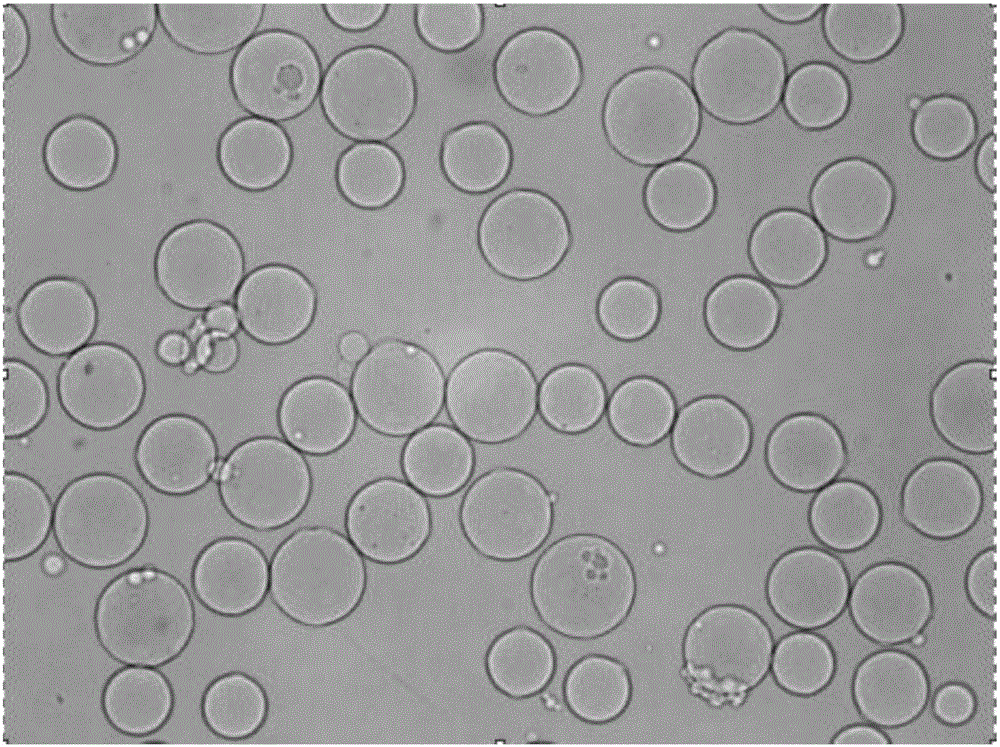

[0044] Take 15 g of agarose in 250 mL of water (concentration of agarose aqueous solution is 6%), stir at room temperature for 1 h, add 0.375 g of KCl and continue stirring for 0.5 h, then heat until the agarose boils and the solution becomes transparent. Prepare 1.625L toluene solution, add 35.3g polyvinyl acetate and 3.53g oleic acid. Stir the organic phase at a constant temperature at 70° C. until uniformly mixed, pour the boiling agarose aqueous solution into the organic phase, and stir for 1 hour to disperse and emulsify the agarose. Add 45g of epichlorohydrin at one time, and add 38mL of 50% NaOH solution dropwise, and the dropwise addition is completed within 1 hour. Stir and solidify for 3 hours before condensing, and control the cooling rate at 2°C / min until the temperature is cooled below 10°C. Agarose gel microspheres with a particle size of 100-300 meshes are prepared after repeated washing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com