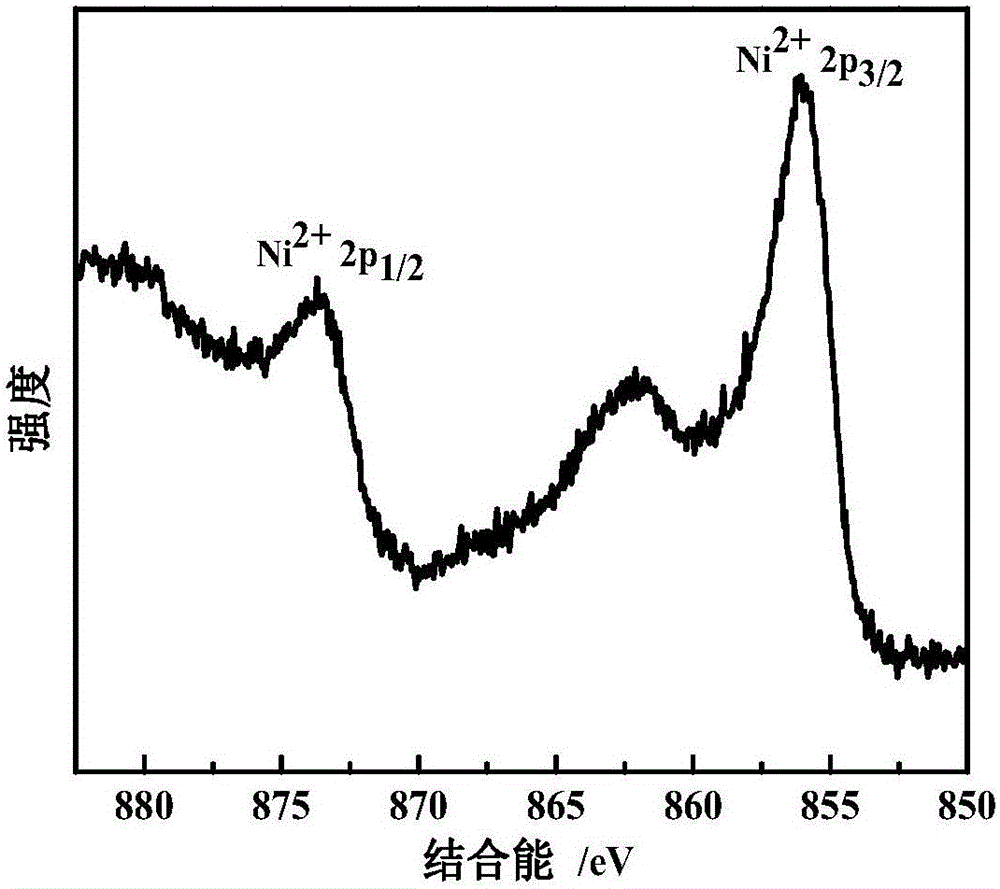

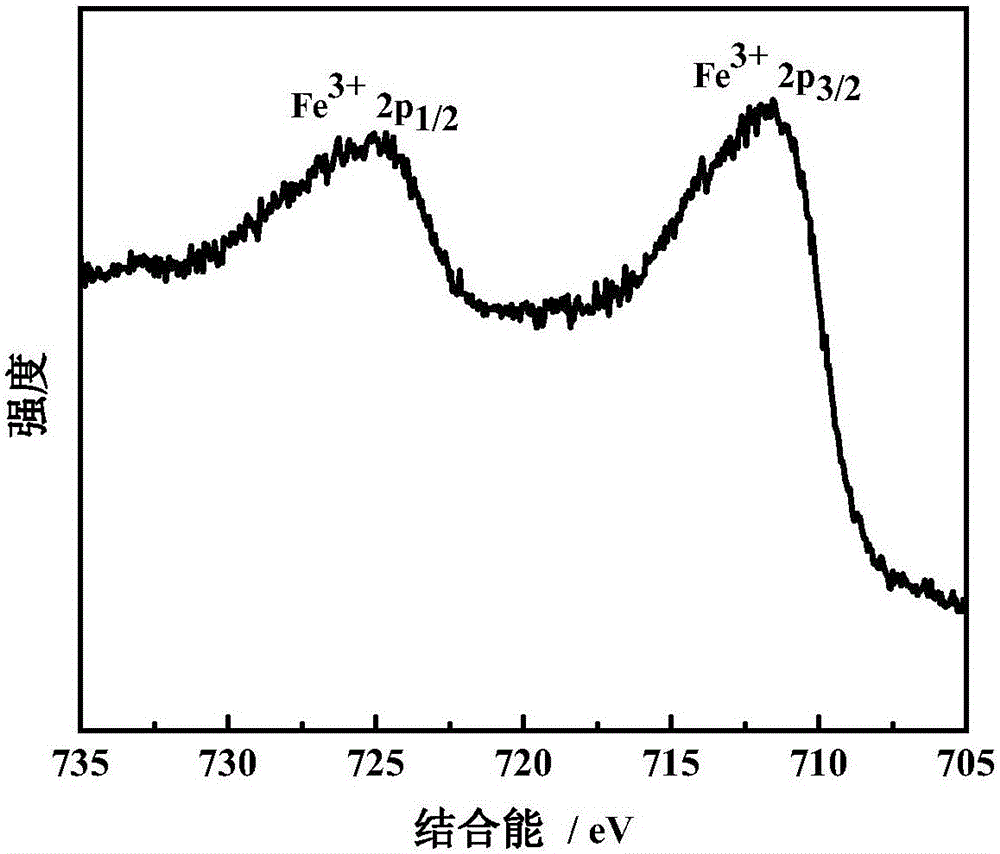

Method for preparing Ni-Fe hydroxide nanometer films through electrodeposition

A technology of hydroxide and nano-film, applied in the direction of nano-technology, electrolytic inorganic material coating, etc., can solve the problems of difficult electrochemical research and poor conductivity, so as to improve the efficiency of electrodeposition, improve the conductivity, and increase the catalytic specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of inverse quaternary ionic liquid microemulsion

[0034] The raw materials composed of the following mass percentages were ultrasonically mixed to prepare an inverse quaternary ionic liquid microemulsion:

[0035]

[0036] The above dissolved Ni(NO 3 ) 2 and Fe(NO 3 ) 3 Ni(NO 3 ) 2 and Fe(NO 3 ) 3 The concentration is 0.75mol / L, that is, the Ni(NO 3 ) 2 and Fe(NO 3 ) 3 The molar ratio is 5:5.

[0037] 2. Electrodeposition of Ni-Fe hydroxide nano film

[0038] After the copper sheet is polished, it is ultrasonically cleaned with dilute sulfuric acid, ethanol, and twice distilled water for 5 minutes. The copper sheet after cleaning is used as the working electrode, and two platinum electrodes are used as the counter electrode and the reference electrode respectively, and are put into the reverse phase quaternary ionic liquid microemulsion prepared in step 1, and the deposition potential is controlled to be -1.5V, and the deposition time is ...

Embodiment 2

[0040] In this example, the raw materials composed of the following mass percentages were ultrasonically mixed uniformly to prepare a reversed-phase quaternary ionic liquid microemulsion:

[0041]

[0042] The above dissolved Ni(NO 3 ) 2 and Fe(NO 3 ) 3 Ni(NO 3 ) 2 and Fe(NO 3 ) 3The concentration is 0.75mol / L, that is, the Ni(NO 3 ) 2 and Fe(NO 3 ) 3 The molar ratio is 5:5.

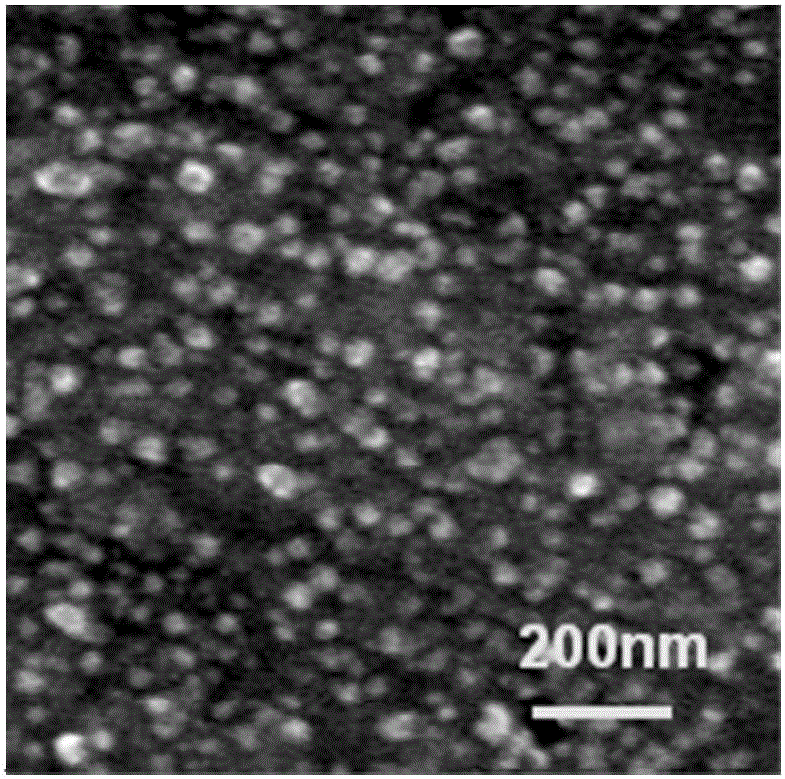

[0043] Other steps are identical with embodiment 1, deposit one deck Ni-Fe hydroxide nano film on copper sheet, the particle diameter of Ni-Fe hydroxide is 25nm (see Figure 4 ).

Embodiment 3

[0045] In this example, the raw materials composed of the following mass percentages were ultrasonically mixed uniformly to prepare a reversed-phase quaternary ionic liquid microemulsion:

[0046]

[0047] The above dissolved Ni(NO 3 ) 2 and Fe(NO 3 ) 3 Ni(NO 3 ) 2 and Fe(NO 3 ) 3 The concentration is 0.75mol / L, that is, the Ni(NO 3 ) 2 and Fe(NO 3 ) 3 The molar ratio is 5:5.

[0048] Other steps are identical with embodiment 1, deposit one deck Ni-Fe hydroxide nano film on copper sheet, the particle diameter of Ni-Fe hydroxide is 40nm (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com