System treatment method for oil field oily sludge

A technology of landing oil sludge and treatment methods, which is applied in the direction of combustion methods, combustion types, incinerators, etc., and can solve problems such as poor effect, secondary pollution, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

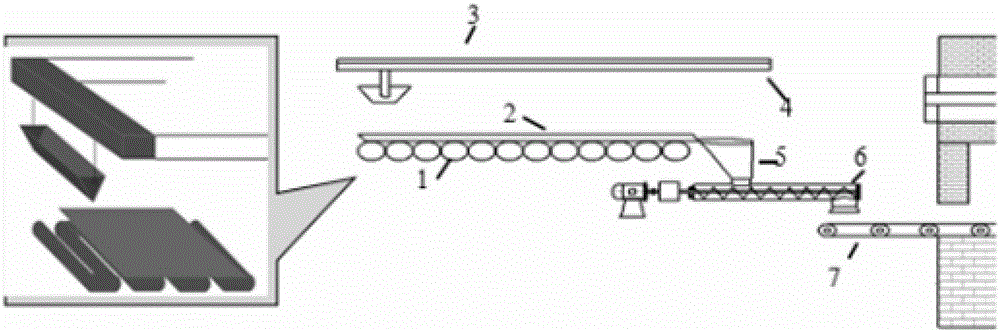

[0018] The present invention will be further described below in conjunction with accompanying drawing:

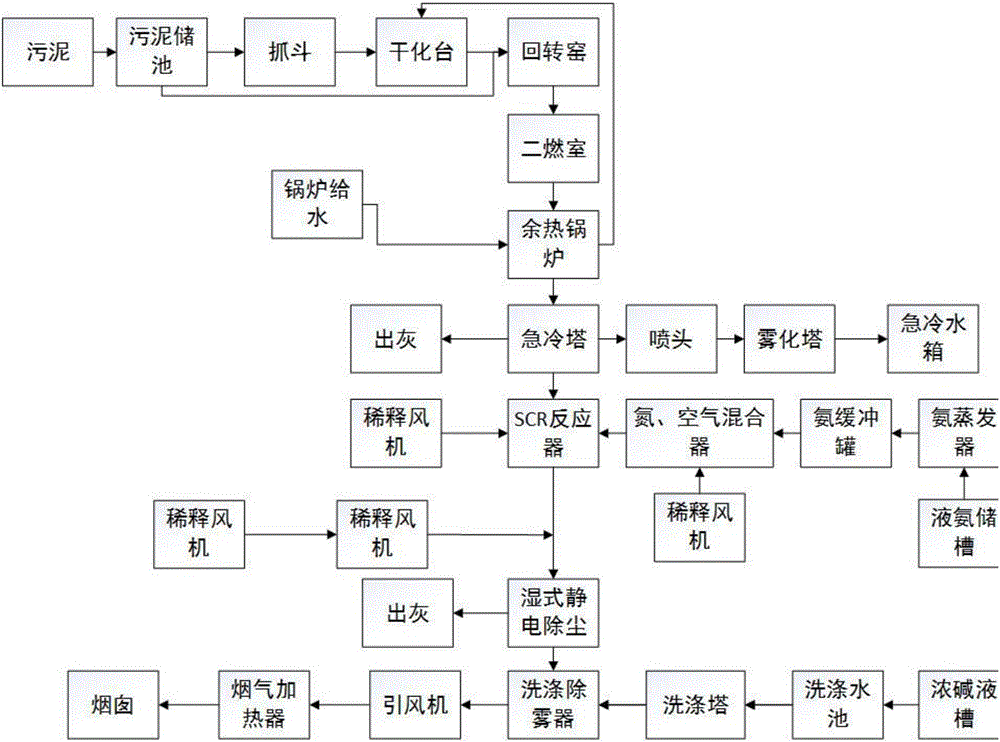

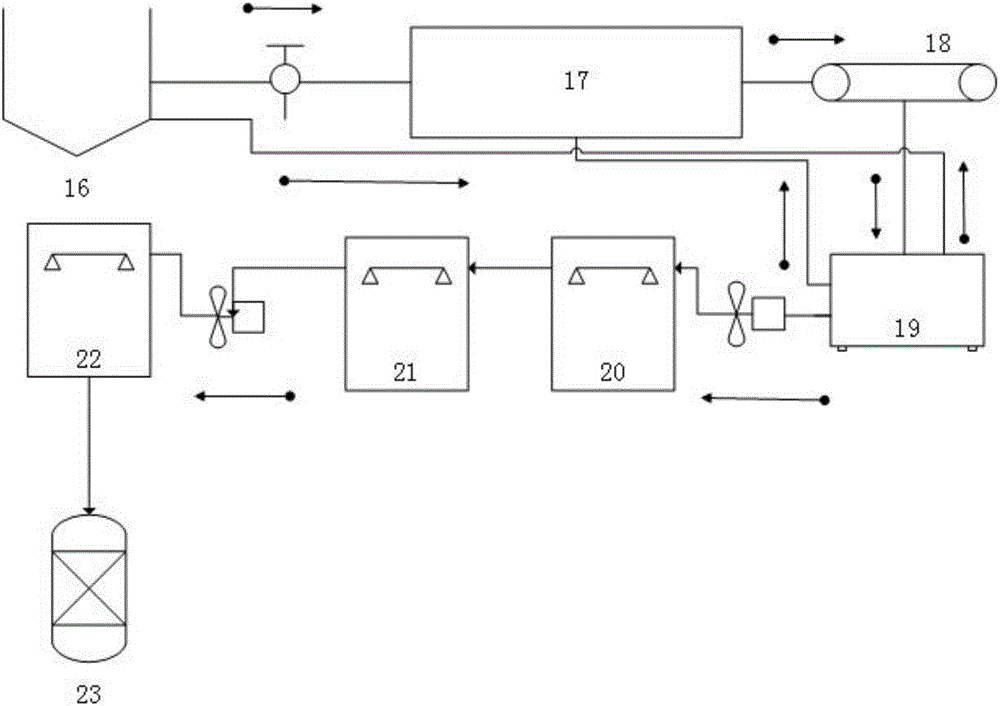

[0019] Depend on Figure 1 to Figure 4 As shown, the systematic treatment method of this kind of oilfield oil sludge consists of the following steps:

[0020] In the first step, the sludge is sieved through the drum screen, and the material with a particle size larger than 300mm is directly sent to the rotary kiln for incineration, and the rest of the sludge is sent to the geothermal drying table for drying at 70-80°C After treatment, the oil is recovered through the oil collection system, and the moisture content of the sludge after drying is controlled below 40%;

[0021] In the second step, the sludge dried in the first step is collected and then enters the rotary kiln through a screw conveying system with a weighing system according to the weight ratio of gas and fuel. Natural gas is used as auxiliary fuel, and the incineration temperature is controlled at 900 ° C to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com